Millimeter-wave high-gain and high-radiation-efficiency slot antenna array based on ridge gap waveguide

A technology of gap waveguide and millimeter wave, which is applied in the direction of antenna array, antenna, radiation element structure, etc., can solve the problems of increased processing cost and high processing precision requirements, and achieve the goal of reducing processing cost, reducing weight and high radiation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

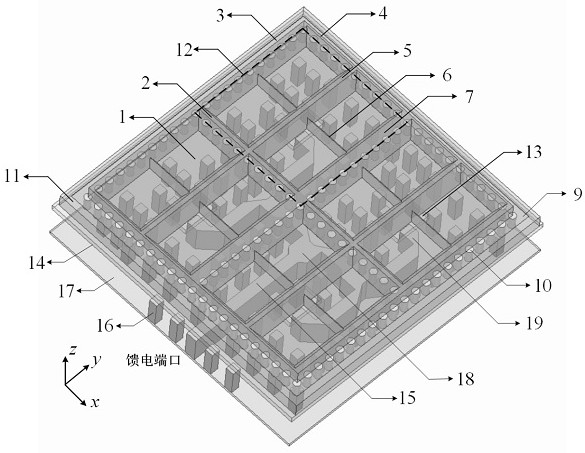

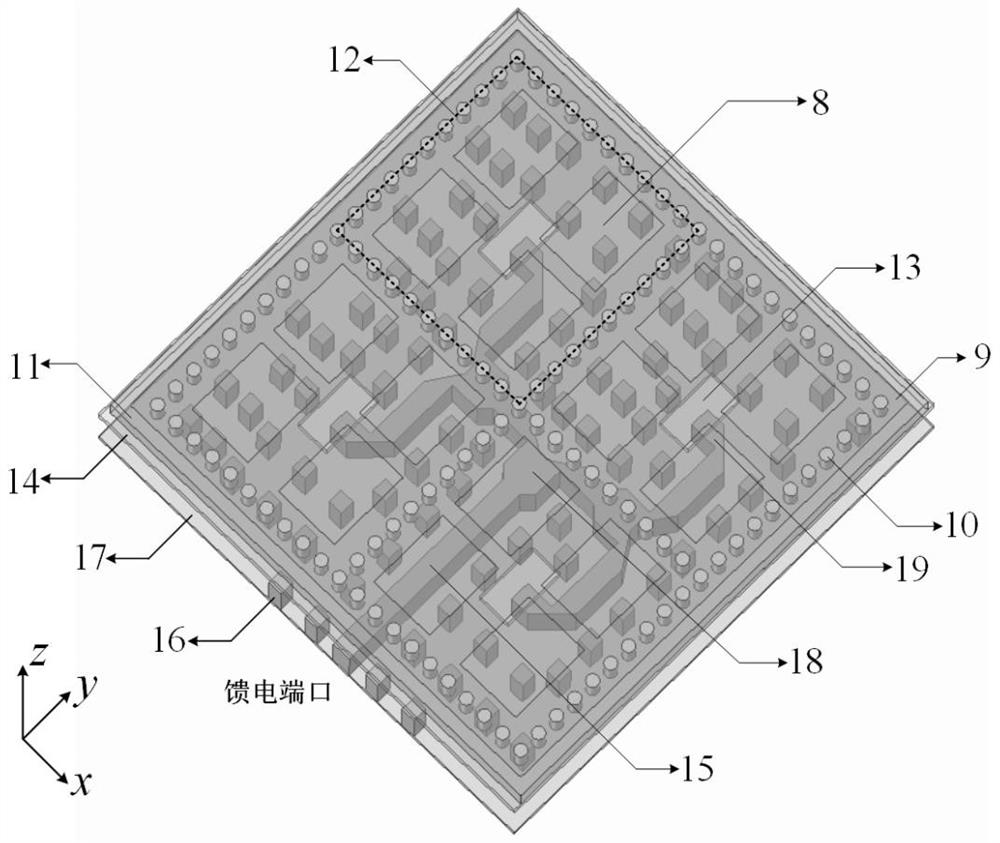

[0021] As shown in Figure 1(a), the millimeter-wave high-gain and high-radiation-efficiency slot antenna array based on the ridge-gap waveguide of the present invention includes an upper, middle and lower three-layer structure, as shown in Figure 1(b) and (c):

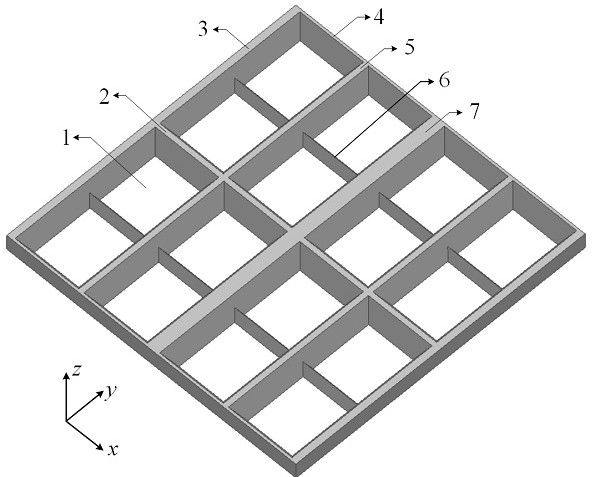

[0022] The uppermost layer is the radiating unit layer, which contains 16 radiating units 1 with inverted trapezoidal grooves of the same size, and metal strips 2, 3, 4, 5, 6, 7 periodically separate the 16 radiating units 1 with inverted trapezoidal grooves. The middle layer is a substrate integrated waveguide high-order mode resonant cavity feed layer processed by multi-layer printed circuit board technology. It consists of a three-layer planar structure from top to bottom, and the metal plate, dielectric substrate and metal printing surface are closely spaced. Fitting; on the top is a metal printing surface 9 with 16 rectangular slits 8, and the 16 rectangular slits 8 are aligned with the bottom surface of the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com