Motor components, air blowers, home appliances and electric vehicles

A technology of motor components and components, applied in the direction of electric components, electric vehicles, electromechanical devices, etc., can solve the problems of large space occupation, insufficient integration, and many heating power devices, so as to reduce the occupied space, save PCB space, Enhance the effect of interior space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

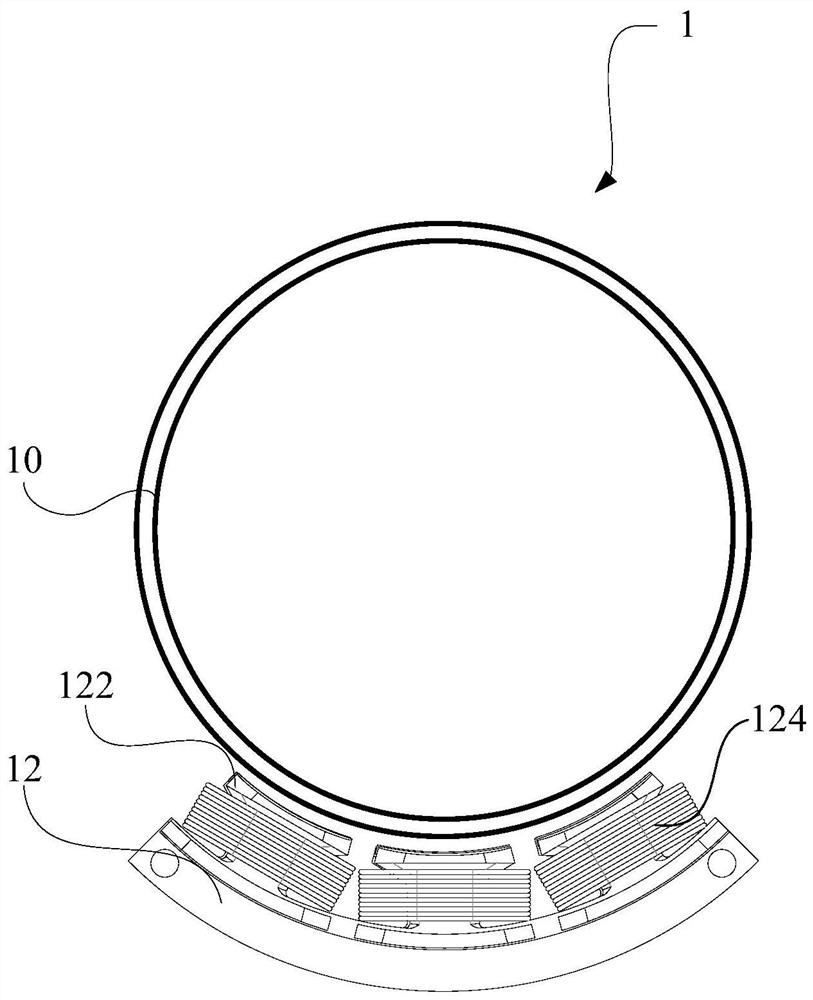

[0056] A motor assembly such as figure 1 As shown, including: motor 1 and control device.

[0057] The motor 1 includes: a rotor assembly 10; a stator assembly 12, the stator assembly 12 has a mating surface matched with the rotor assembly 10, and the mating surface is opposite to a part of the outer peripheral surface of the rotor assembly 10, so that the rotor assembly 10 can follow the diameter of the rotor assembly 10. The stator assembly 12 is separated from the stator assembly 12 in the axial direction and / or the axial direction; the stator assembly 12 includes: a stator iron core with stator teeth 122 thereon; at least two stator windings 124, respectively disposed on the stator teeth 122, any adjacent two The polarities of the stator windings 124 are different.

[0058] The control device is connected to the motor 1 , and is configured to detect the electrical signal of the motor 1 , determine the position of the rotor assembly 10 according to the electrical signal, a...

Embodiment 2

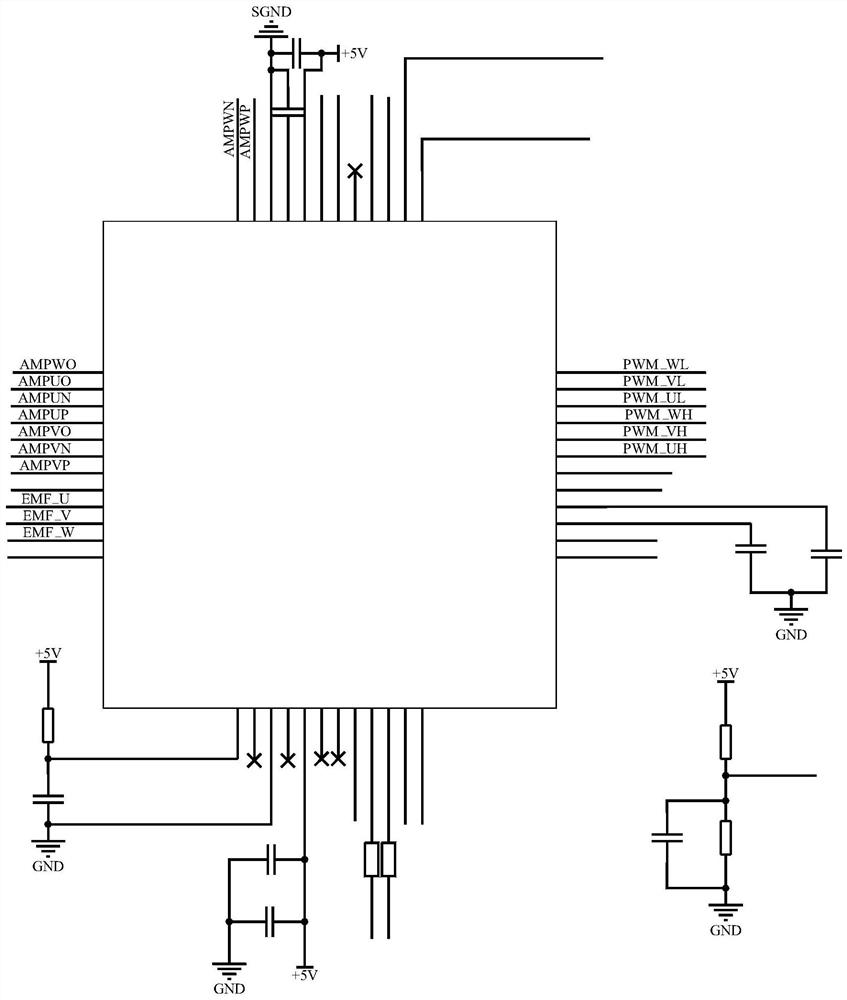

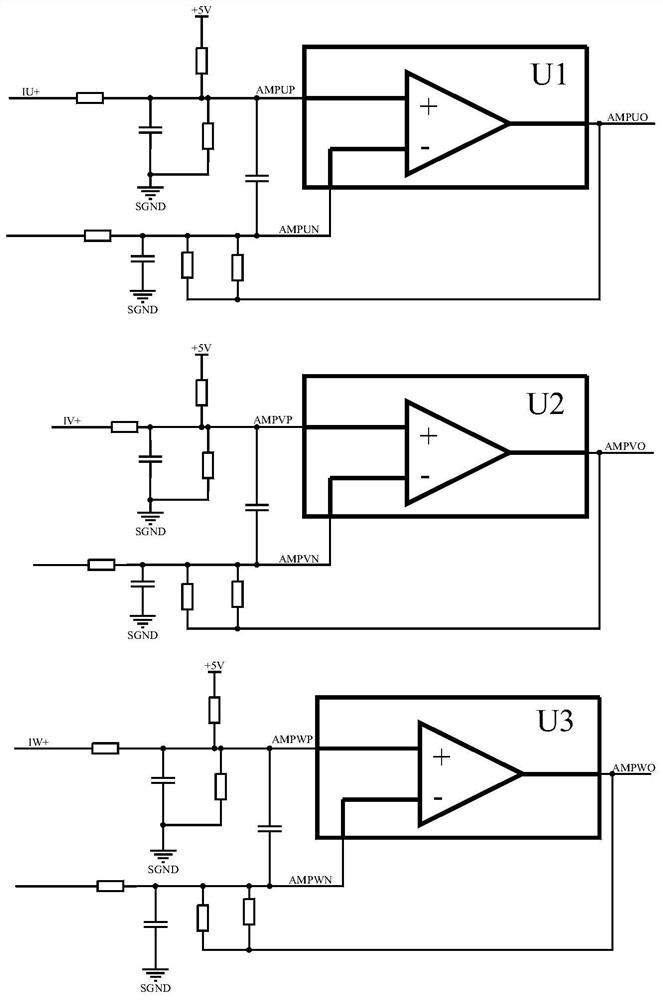

[0067] In the above embodiment, as figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, the motor assembly includes a motor assembly and a control device, and the control device includes: a phase current detection circuit, a phase voltage detection circuit, a control circuit and a zero-crossing detection circuit; the phase current detection circuit is configured to obtain the motor based on the zero-crossing time of the electrical signal. The phase current of the motor; the phase voltage detection circuit is configured to obtain the phase voltage of the motor based on the zero-crossing moment; the control circuit is connected with the phase current detection circuit and the phase voltage detection circuit, and the control circuit is configured to be adapted to determine according to the phase current and the phase voltage the position of the rotor, and generate a control signal according to the position of the rotor to control the stator assembly to drive the...

Embodiment 3

[0080] In an embodiment of the present invention, the control device further includes: a motor drive circuit connected to the control circuit, the motor drive circuit is configured to generate a corresponding drive current according to the control signal, and control the stator assembly to drive the rotor assembly through the drive current .

[0081] In this embodiment, the control device includes a motor drive circuit, the motor drive circuit is connected to the control circuit, the motor drive circuit generates a corresponding drive current according to the control signal, the motor drive circuit outputs the drive current to the stator assembly, and controls the drive rotor The rotational state of the component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com