Lysostaphin and chitosan composite antibacterial film spraying agent

A lysostaphin and compound antibacterial technology, applied in the direction of enzyme, peptidase, hydrolase, etc., can solve the problems of poor fit of the wound, secondary infection of the wound, and film shedding, so as to prevent the secondary infection of external bacteria. Infection, no irritation to the skin, and the effect of not easy to remove the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

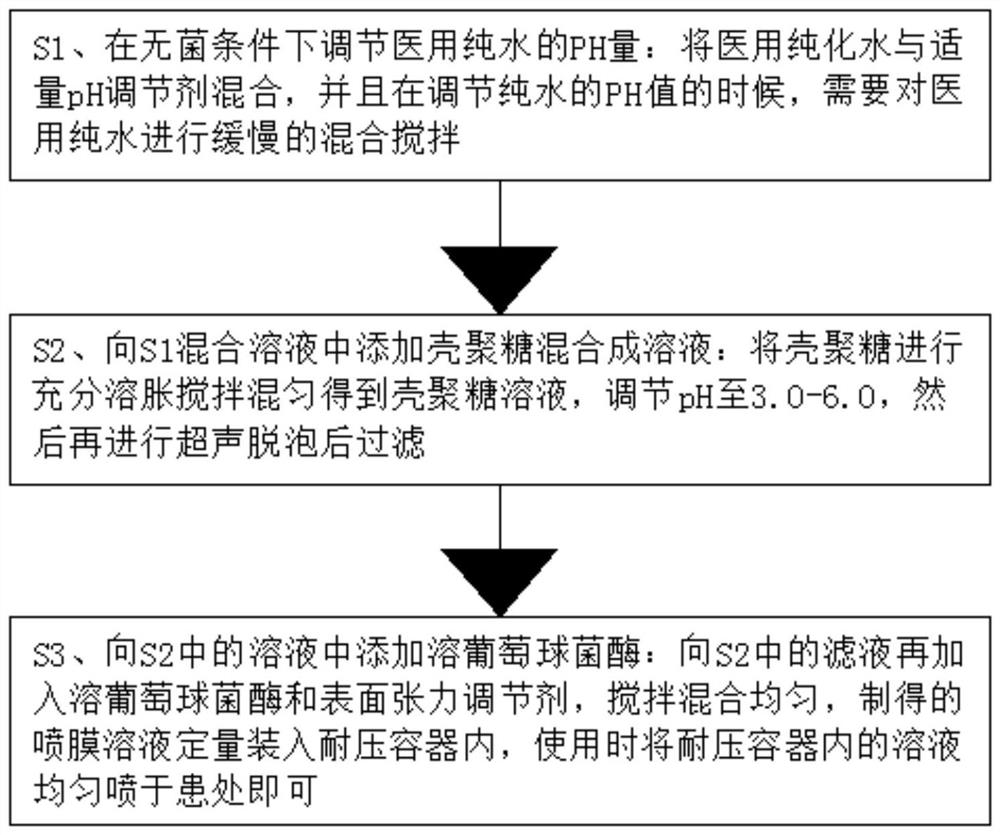

Method used

Image

Examples

Embodiment 1

[0027] A lysostaphin and chitosan composite antibacterial spray film agent, the raw materials for preparing the composite gel, in terms of mass volume percentage, include 1% lysostaphin, 0.5% chitosan, and 0.1% surface tension regulator , pH regulator 0.6%, medical purified water balance.

[0028] In order to make the molecules small enough so that the formed film can form a breathable film, the compound antibacterial spray film can effectively kill Gram-positive and Gram-negative bacteria, and can promote wound healing and tissue repair without irritation to the skin Properties, in the present embodiment, preferably, described chitosan molecular weight is 10000, and deacetylation degree 80%.

[0029] In order to form tension on the surface of the film without causing the film to fall off, or to prevent the skin from being pulled and injured again, the compound antibacterial spray film can effectively and quickly form a water-insoluble protective film on the wound surface, and...

Embodiment 2

[0041] A lysostaphin and chitosan composite antibacterial spray film agent, the raw material for preparing the composite gel, in terms of mass volume percentage, includes 5% lysostaphin, 2% chitosan, and 2% surface tension regulator , pH regulator 0.9%, medical purified water balance.

[0042] In order to make the molecules small enough so that the formed film can form a breathable film, the compound antibacterial spray film can effectively kill Gram-positive and Gram-negative bacteria, and can promote wound healing and tissue repair without irritation to the skin Properties, in the present embodiment, preferably, described chitosan molecular weight is 500000, and deacetylation degree 85%.

[0043] In order to form tension on the surface of the film without causing the film to fall off, or to prevent the skin from being pulled and injured again, the compound antibacterial spray film can effectively and quickly form a water-insoluble protective film on the wound surface, and the ...

Embodiment 3

[0055] Under sterile conditions, use medical purified water and hydrochloric acid to prepare a hydrochloric acid solution with a concentration of 1% (by mass volume percentage), and add 3% (by mass volume percentage) of chitosan with a molecular weight of 200,000 and a deacetylation degree of 90%. Stir to make it fully swell to obtain a chitosan solution, adjust the pH to 3.0-6.0, filter after ultrasonic degassing, add 10% (mass volume percentage) lysostaphin and 4% (mass volume percentage) surface tension to the filtrate Regulator, stir and mix evenly, put the prepared spray film solution quantitatively into a pressure-resistant container, and spray the solution in the pressure-resistant container evenly on the affected part when in use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com