Anti-aging EVA (Ethylene Vinyl Acetate) hot melt adhesive film and preparation method thereof

A hot-melt adhesive film and anti-aging technology, which is applied in the field of EVA hot-melt adhesive, can solve the problems of EVA adhesive film falling off, and achieve the effect of improving bonding strength and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

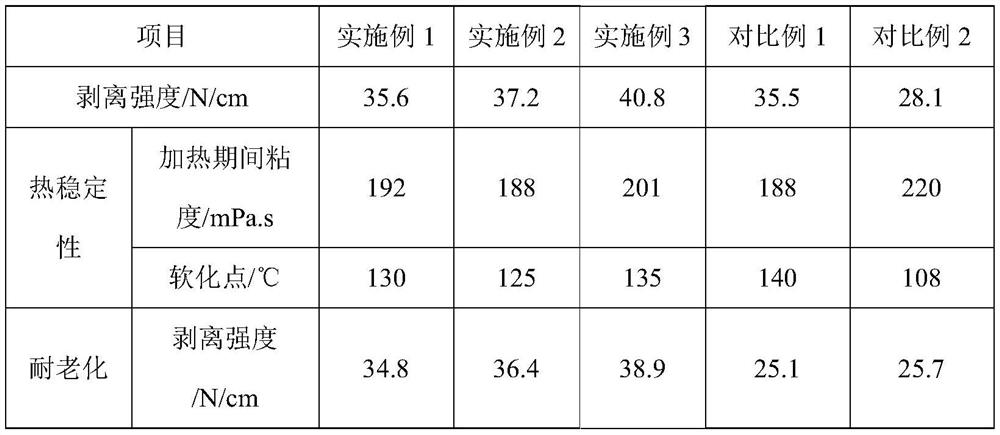

Examples

Embodiment 1

[0027] An aging-resistant EVA hot-melt adhesive film, comprising the following components by weight:

[0028] 40 parts of EVA main resin; 1 part of epichlorohydrin rubber elastomer; 10 parts of polyisocyanate compound with urethane bond; 3 parts of tackifier; 0.1 part of initiator; 0.01 part of antioxidant.

[0029] The preparation method of this aging-resistant EVA hot-melt adhesive film comprises following preparation steps:

[0030] S1: Add EVA main resin, epichlorohydrin rubber elastomer, polyisocyanate compound with urethane bond, tackifier, initiator and antioxidant into a high-speed mixer and mix evenly to obtain a mixed material;

[0031] S2: Put the mixed material into a screw extruder and melt and extrude at 140°C, and then go through the steps of spreading, cooling, drawing and winding to obtain an EVA hot-melt adhesive film with high water vapor barrier property.

Embodiment 2

[0033] An aging-resistant EVA hot-melt adhesive film, comprising the following components by weight:

[0034] 50 parts of EVA main resin; 3 parts of epichlorohydrin rubber elastomer; 12 parts of polyisocyanate compound with urethane bond; 7 parts of tackifier; 0.5 part of initiator; 0.5 part of antioxidant.

[0035] The preparation method of this aging-resistant EVA hot-melt adhesive film comprises following preparation steps:

[0036] S1: Add EVA main resin, epichlorohydrin rubber elastomer, polyisocyanate compound with urethane bond, tackifier, initiator and antioxidant into a high-speed mixer and mix evenly to obtain a mixed material;

[0037] S2: Put the mixed material into a screw extruder and melt and extrude at 140°C, and then go through the steps of spreading, cooling, drawing and winding to obtain an EVA hot-melt adhesive film with high water vapor barrier property.

Embodiment 3

[0039] An aging-resistant EVA hot-melt adhesive film, comprising the following components by weight:

[0040] 60 parts of EVA main resin; 5 parts of epichlorohydrin rubber elastomer; 15 parts of polyisocyanate compound with urethane bond; 10 parts of tackifier; 1 part of initiator; 1 part of antioxidant.

[0041] The preparation method of this aging-resistant EVA hot-melt adhesive film comprises following preparation steps:

[0042] S1: Add EVA main resin, epichlorohydrin rubber elastomer, polyisocyanate compound with urethane bond, tackifier, initiator and antioxidant into a high-speed mixer and mix evenly to obtain a mixed material;

[0043] S2: Put the mixed material into a screw extruder and melt and extrude at 140°C, and then go through the steps of spreading, cooling, drawing and winding to obtain an EVA hot-melt adhesive film with high water vapor barrier property.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com