Preparation method of nano-assembly with AIE effect

A nano-assembly and effect technology, applied in the fields of sulfonate preparation, chemical instruments and methods, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

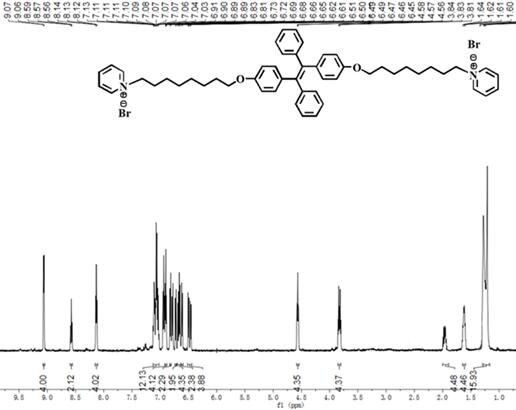

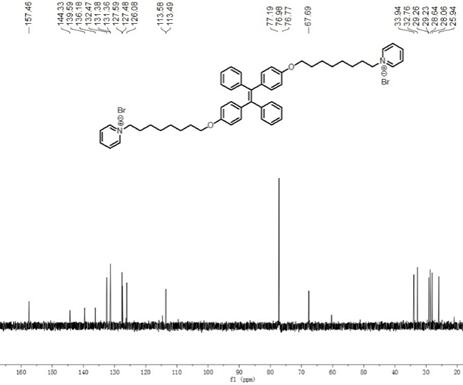

Image

Examples

Embodiment 2

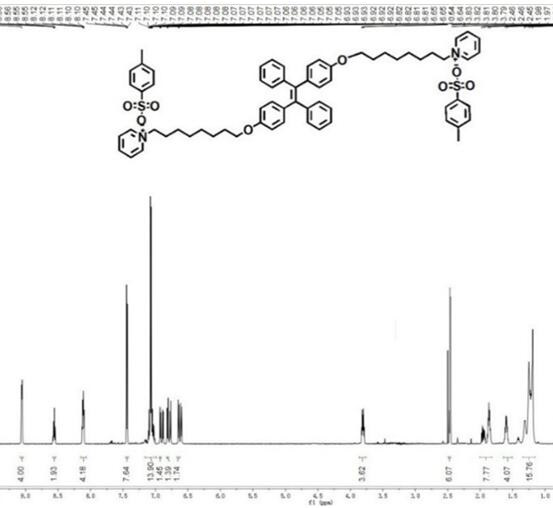

[0066] Synthesis of Example 2 TPE-ONS

[0067] Dissolve TPE-ON (0.18g, 0.1mol) in 3mL of methanol solution, dissolve sodium p-toluenesulfonate (0.15g, 0.2mol) in 3mL of deionized water, mix the two solutions, and stir at room temperature After 12 hours, after the reaction was complete, the reaction solution was poured into water, the reaction system was extracted with dichloromethane, washed three times with saturated brine, the organic phases were combined, dried and filtered with anhydrous magnesium sulfate, the filtrate was spin-dried, passed It was separated and purified by column chromatography to obtain a light yellow oily solid with a yield of 62%.

[0068] 1 H NMR (600 MHz, DMSO- d 6 ) δ 9.06 (d, J = 2.1 Hz, 4H), 8.58 – 8.55 (m,2H), 8.13 – 8.08 (m, 4H), 7.45 – 7.43 (m, 8H), 7.11 – 7.02 (m, 4H), 6.94 –6.91 (m, 8H ), 6.83 – 6.80 (m, 2H), 6.66 – 6.62 (m, 4H), 3.81 (dt, J = 12.4,6.4 Hz, 4H), 2.46 (d, J = 1.9 Hz, 6H), 1.98 – 1.82 (m, 4H), 1.63 – 1.56 (m,8H), 1.28 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com