ABS composite material as well as preparation method and application thereof

A composite material and ABS resin technology, applied in the field of modified plastics, can solve the problems of stress whitening and poor chemical resistance, achieve low stress whitening, improve processing fluidity, and reduce the probability of stress whitening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

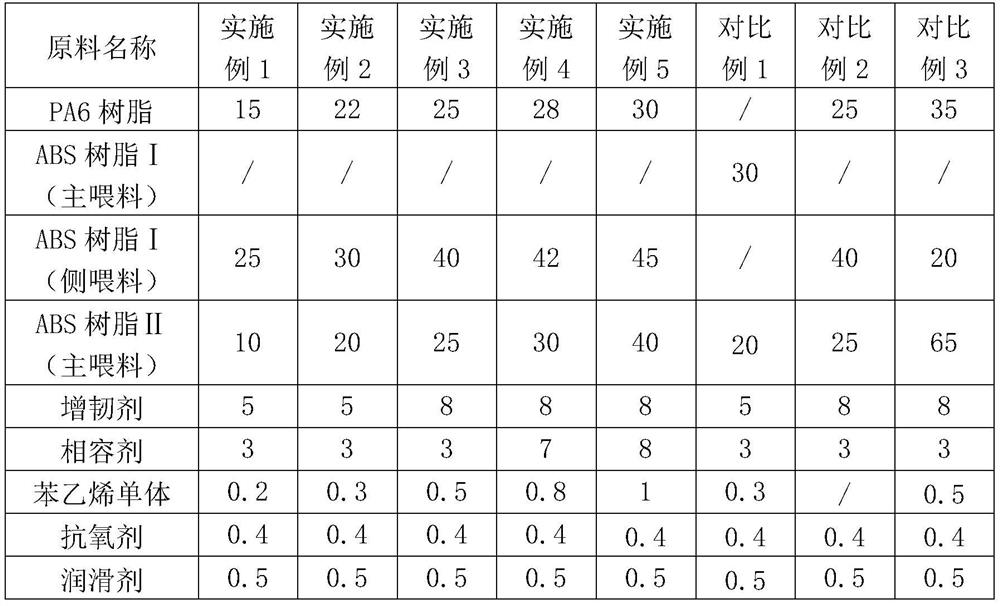

[0045] A kind of ABS composite material with low stress whitening and excellent chemical resistance, its raw material formula is as shown in table 1, and its preparation method comprises the following steps:

[0046] Mix the above-mentioned raw materials except ABS resin Ⅰ evenly, and then feed them from the main feeding port of the extruder. The ABS resin Ⅰ is weighed by side feeding, and then fed into the barrel of the extruder; the raw materials are melted in the extruder , extrusion and granulation to obtain ABS composite materials with low stress whitening and excellent chemical resistance.

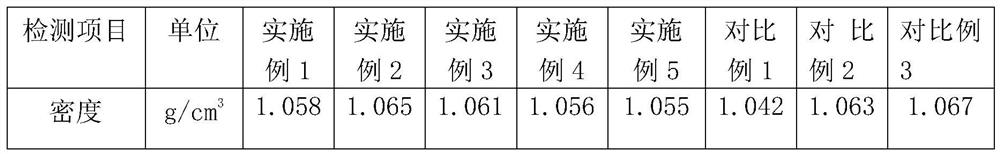

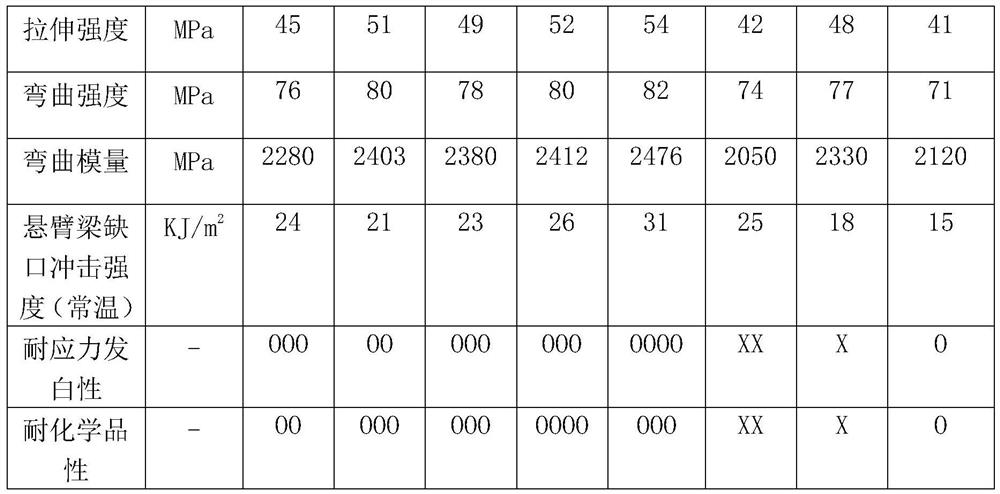

[0047] The pellets were injection molded into corresponding samples for testing, and the test results are shown in Table 2.

Embodiment 3

[0058] Compared with Comparative Example 2, Example 3 added styrene monomer, and the stress whitening resistance of the ABS composite material obtained in Example 3 was significantly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com