A kind of hydrophilic film and preparation method thereof

A hydrophilic membrane and hydrophobic technology, applied in the field of hydrophilic membrane and its preparation, can solve the problems of improved anti-pollution ability, unsatisfactory protein retention rate, large proportion of cellulose acetate added, etc., to achieve pure water flux and protein retention rate increase, improve filtration performance and anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

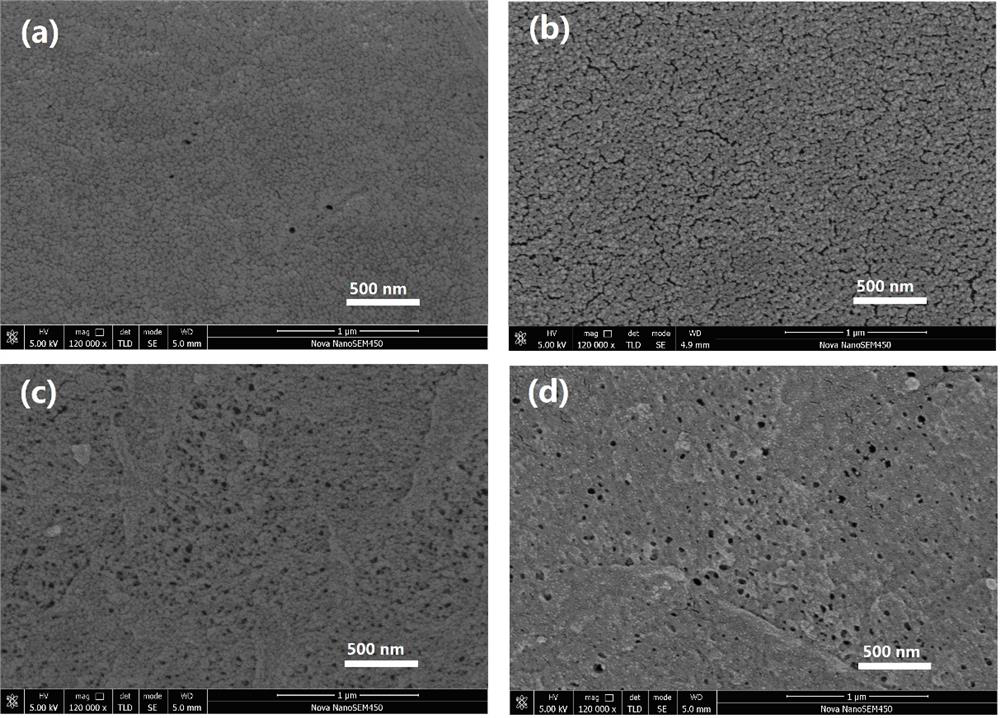

Image

Examples

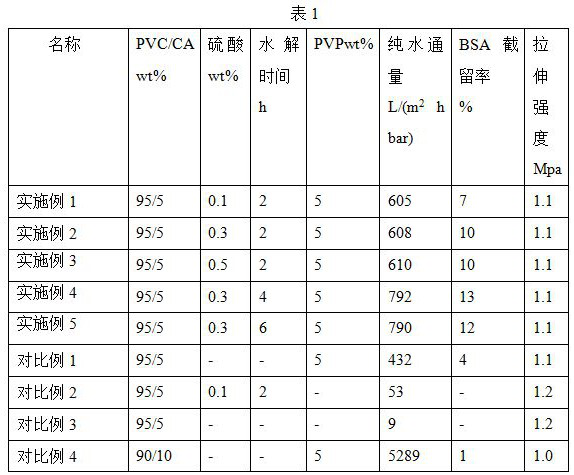

Embodiment 1

[0021] (1) Dissolve 50 grams of PVC and 25 grams of PVP in 425 grams of DMAc to obtain a PVC (10wt%) solution. 50 g of CA and 25 g of PVP were dissolved in 425 g of DMAc to obtain a CA (10 wt%) solution.

[0022] (2) Mix the PVC solution and the CA solution at a ratio of 95 / 5wt% to obtain a PVC / CA blend solution.

[0023] (3) Apply the PVC / CA blended solution on a clean glass plate with an adjustable film applicator, and then immerse it in water for 4 hours, during which time the water is changed every 10 minutes. The blended membrane was peeled off from the glass plate and cleaned with deionized water to obtain a hydrophilic PVC / CA filter membrane.

[0024] (4) Immerse the PVC / CA film obtained by the above method in 0.1g / L dilute sulfuric acid aqueous solution, and hydrolyze it at 60°C for 2 hours. Then the membrane was taken out and cleaned with deionized water to obtain a hydrolytically modified PVC / CA blend membrane.

[0025] (5) According to the experimental method, th...

Embodiment 2

[0027] (1) Dissolve 50 grams of PVC and 25 grams of PVP in 425 grams of DMAc to obtain a PVC (10wt%) solution. 50 g of CA and 25 g of PVP were dissolved in 425 g of DMAc to obtain a CA (10 wt%) solution.

[0028] (2) Mix the PVC solution and the CA solution at a ratio of 95 / 5wt% to obtain a PVC / CA blend solution.

[0029] (3) Apply the PVC / CA blended solution on a clean glass plate with an adjustable film applicator, and then immerse it in water for 4 hours, during which time the water is changed every 10 minutes. The blended membrane was peeled off from the glass plate and cleaned with deionized water to obtain a hydrophilic PVC / CA filter membrane.

[0030] (4) Immerse the PVC / CA film obtained by the above method in 0.3g / L dilute sulfuric acid aqueous solution, and hydrolyze it at 60°C for 2 hours. Then the membrane was taken out and cleaned with deionized water to obtain a hydrolytically modified PVC / CA blend membrane.

[0031] (5) According to the experimental method, th...

Embodiment 3

[0033] (1) Dissolve 50 grams of PVC and 25 grams of PVP in 425 grams of DMAc to obtain a PVC (10wt%) solution. 50 g of CA and 25 g of PVP were dissolved in 425 g of DMAc to obtain a CA (10 wt%) solution.

[0034] (2) Mix the PVC solution and the CA solution at a ratio of 95 / 5wt% to obtain a PVC / CA blend solution.

[0035] (3) Apply the PVC / CA blended solution on a clean glass plate with an adjustable film applicator, and then immerse it in water for 4 hours, during which time the water is changed every 10 minutes. The blended membrane was peeled off from the glass plate and cleaned with deionized water to obtain a hydrophilic PVC / CA filter membrane.

[0036] (4) Immerse the PVC / CA film obtained by the above method in 0.5g / L dilute sulfuric acid aqueous solution, and hydrolyze it at 60°C for 2 hours. Then the membrane was taken out and cleaned with deionized water to obtain a hydrolytically modified PVC / CA blend membrane.

[0037] (5) According to the experimental method, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com