Method and device for purifying dicyclopentadiene

A technology of dicyclopentadiene and materials, applied in the field of purification of dicyclopentadiene, can solve the problems of low yield of dicyclopentadiene, poor product quality and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

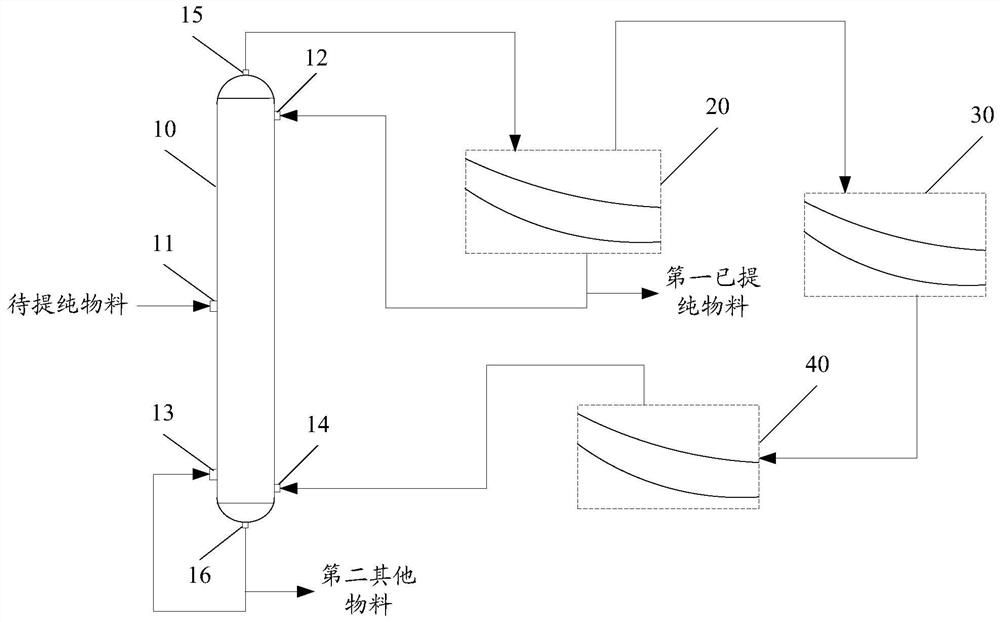

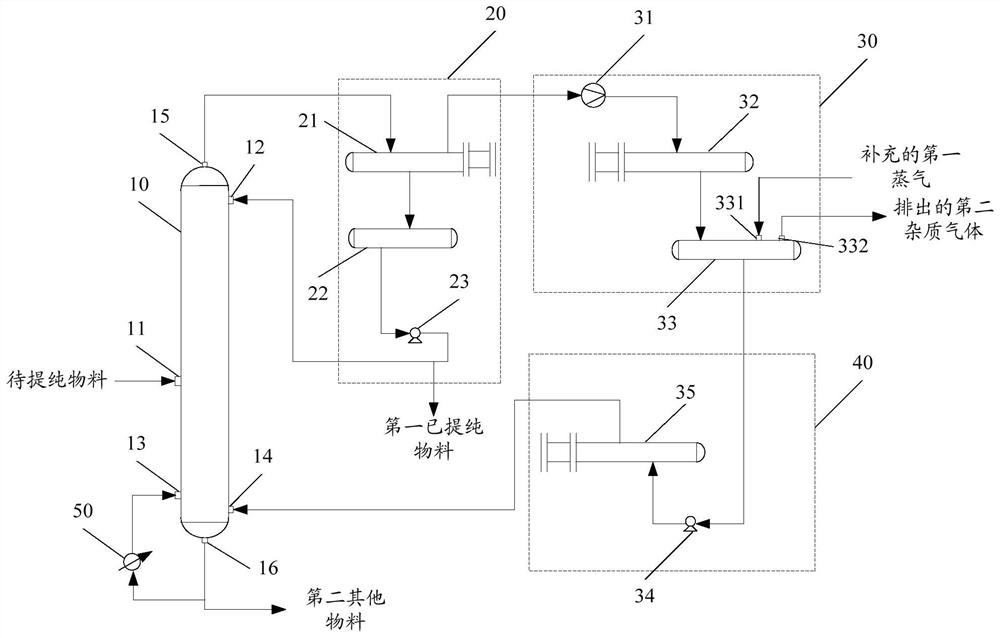

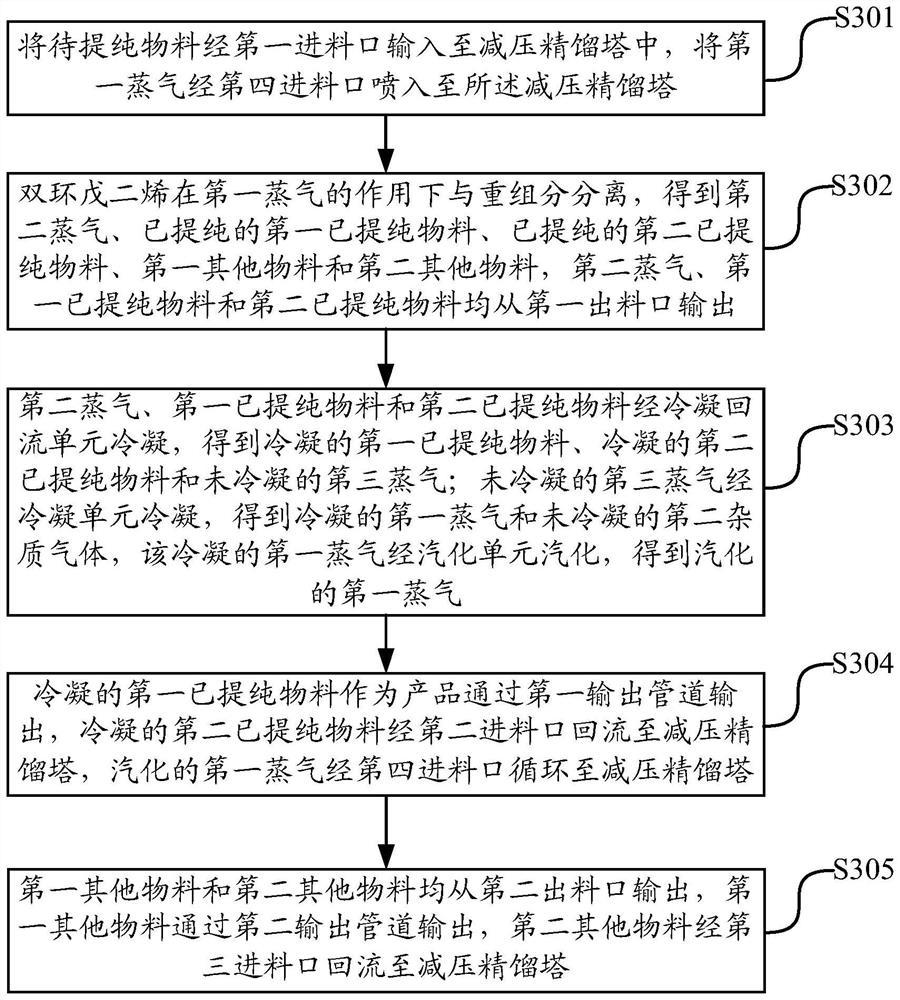

Image

Examples

Embodiment 1

[0120] The feed rate of the material to be purified is 2500t / h, including: 2% C6 fraction, 0.3% cyclopentadiene, 60.8% dicyclopentadiene, 8.8% heavy component and 28.1% other components.

[0121] According to the dicyclopentadiene purification device provided by the embodiment of the present invention, 50 kg / h of n-pentane vapor is injected, and the yield of dicyclopentadiene is 82.5%.

Embodiment 2

[0123] The feed rate of the material to be purified is 2500t / h, including: 2% C6 fraction, 0.3% cyclopentadiene, 60.8% dicyclopentadiene, 8.8% heavy component and 28.1% other components.

[0124] According to the dicyclopentadiene purification device provided by the embodiment of the present invention, 60 kg / h of n-butane vapor is injected, and the yield of dicyclopentadiene is 85%.

Embodiment 3

[0126] The feed rate of the material to be purified is 2500t / h, including: 2% C6 fraction, 0.3% cyclopentadiene, 60.8% dicyclopentadiene, 8.8% heavy component and 28.1% other components.

[0127] According to the dicyclopentadiene purification device provided by the embodiment of the present invention, 50 kg / h of mixed steam of n-pentane, isopentane and cyclopentane was injected, and the yield of dicyclopentadiene was 81%.

[0128] In the dicyclopentadiene purification device provided by the related art, the maximum yield of dicyclopentadiene is 75%. And according to above-mentioned embodiment 1~3 as can be known, the purification device of dicyclopentadiene provided by the present invention is by injecting light hydrocarbon steam, the yield of dicyclopentadiene is maximum 85%, illustrates that dicyclopentadiene provided by the present invention The purification device can improve the yield of dicyclopentadiene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com