Preparation method of phlebopus portentosus polysaccharide

A technology of boletus and polysaccharides, which is applied in the field of preparation of boletus bursa polysaccharides, can solve the problems of difficult structure and composition research, low polysaccharide purity, etc., to improve yield and purity, reduce volume, and facilitate centrifugal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

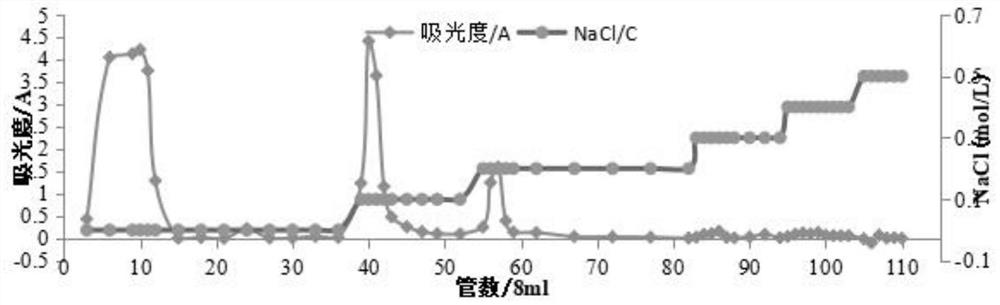

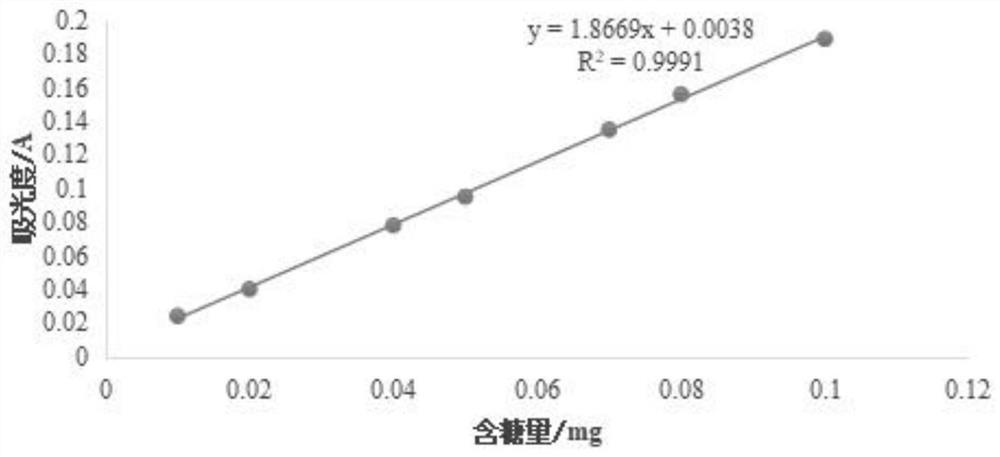

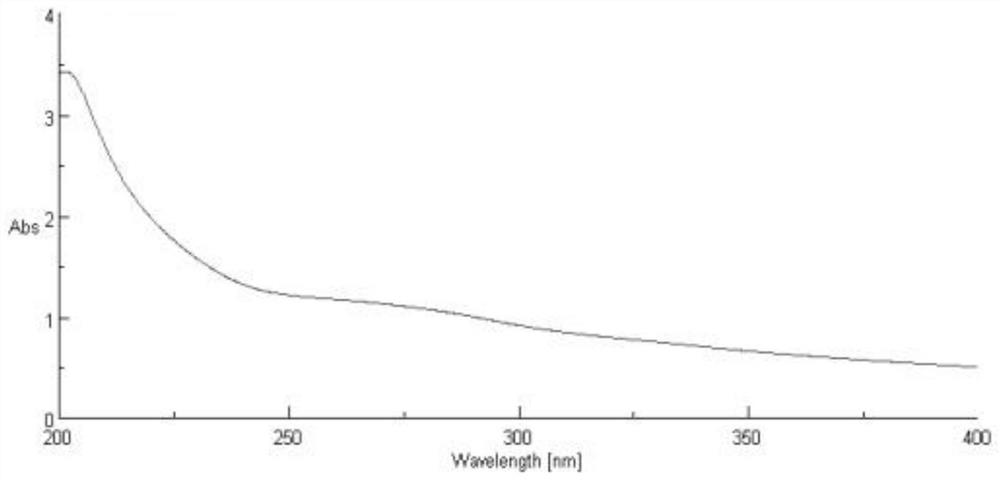

[0042] Extraction and pretreatment of polysaccharides

[0043] Under sterility conditions, a punch having a diameter of 10 mm is punched on a pneumatic dish of the dark brownwheld. The pentarami is inoculated with a five-strand of five strains inoculated in 200 ml of liquid fermentation medium. In a triangular bottle, 25 ° C, 100R / min constant temperature culture 10d, after removal of the filament, combined with the fermentation liquid at 0.08 MPa, 60 ° C for 10 min. The quantitative decorate shank boletus fermentation liquid (6L, each time there are multiple 200 ml fermentation medium while fermenting, totaling 4 batches), concentrated at 0.08 MPa, 60 ° C for 10 min, concentrate, first centrifugal treatment, The supernatant was combined, and then put three times of volume ethanol on the magnetic stirrer, sealing the fresh film, and placed in a refrigerator to precipitate 24 h. After alcohol sink, the centrifugation of the centrifugation was 8000 rpm, 15 min, and after centrifug...

Embodiment 2

[0054] Extraction and pretreatment of polysaccharides

[0055] Under sterility conditions, a punch having a diameter of 10 mm is punched on a pneumatic dish of the dark brownwheld. The pentarami is inoculated with a five-strand of five strains inoculated in 200 ml of liquid fermentation medium. In a triangular bottle, 32 ° C, 200R / min constant temperature culture 15d, after removal, filtrate, mixed with fermentation, concentrated at 0.09 mPa, 40 ° C. The quantitative is taking a dark brown pair of boletus fermentation liquid (6L, each time there are multiple 200 ml fermentation medium, and 4 batches have been completed, concentrated in 0.09 MPa, 40 ° C for 20 min, and concentrate. Centrifugal treatment. The supernatant was combined, and then a 5x volume ethanol was placed on a magnetic stirrer, sealed with a plastic film, and placed in a refrigerator precipitate 24 h. After alcohol sink, the centrifugation was carried out by 8000 rpm, 15 min; after centrifugal ethanol precipitat...

Embodiment 3

[0066] Extraction and pretreatment of polysaccharides

[0067] Under sterility conditions, a punch having a diameter of 10 mm is punched on a pneumatic dish of the dark brownwheld. The pentarami is inoculated with a five-strand of five strains inoculated in 200 ml of liquid fermentation medium. In a triangular bottle, 28 ° C, 150 r / min constant temperature culture was removed, and then filtered off the bacteria, and then the fermentation liquid was mixed at 0.085 MPa, 50 ° C for 15 min. The quantity was taking a fermentation of boletus (6L, each time with a plurality of 200 ml of fermentation medium while fermenting, a total of 4 batches), concentrated in 0.085 MPa, 50 ° C, concentrated to centrifugal treatment, The supernatant was combined, and 4x volume ethanol was placed on a magnetic stirrer, sealed with a fresh film, and placed in a refrigerator precipitate 24 h. After centrifugation, centrifugation was carried out after alcohol, and the centrifugation was 8000 rpm, centrif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average relative molecular weight | aaaaa | aaaaa |

| Relative molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com