Preparation equipment and preparation method of solid electrolyte membrane

A technology of solid electrolyte membrane and solid electrolyte, which is applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems of low strength of solid electrolyte membrane, high hardware investment, high cost, etc. The effect of improving control and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

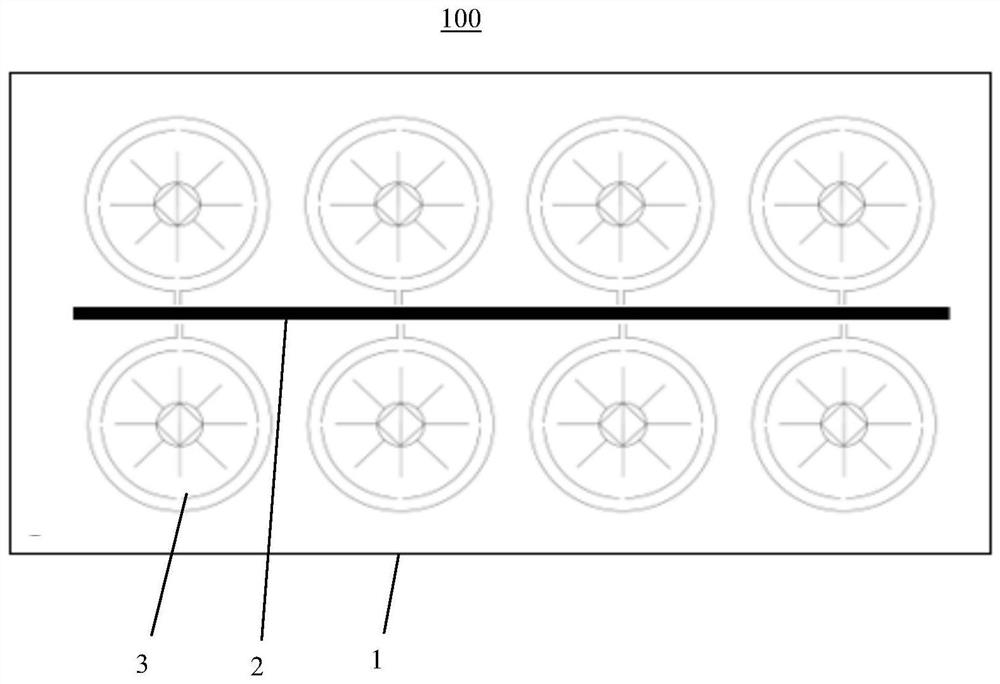

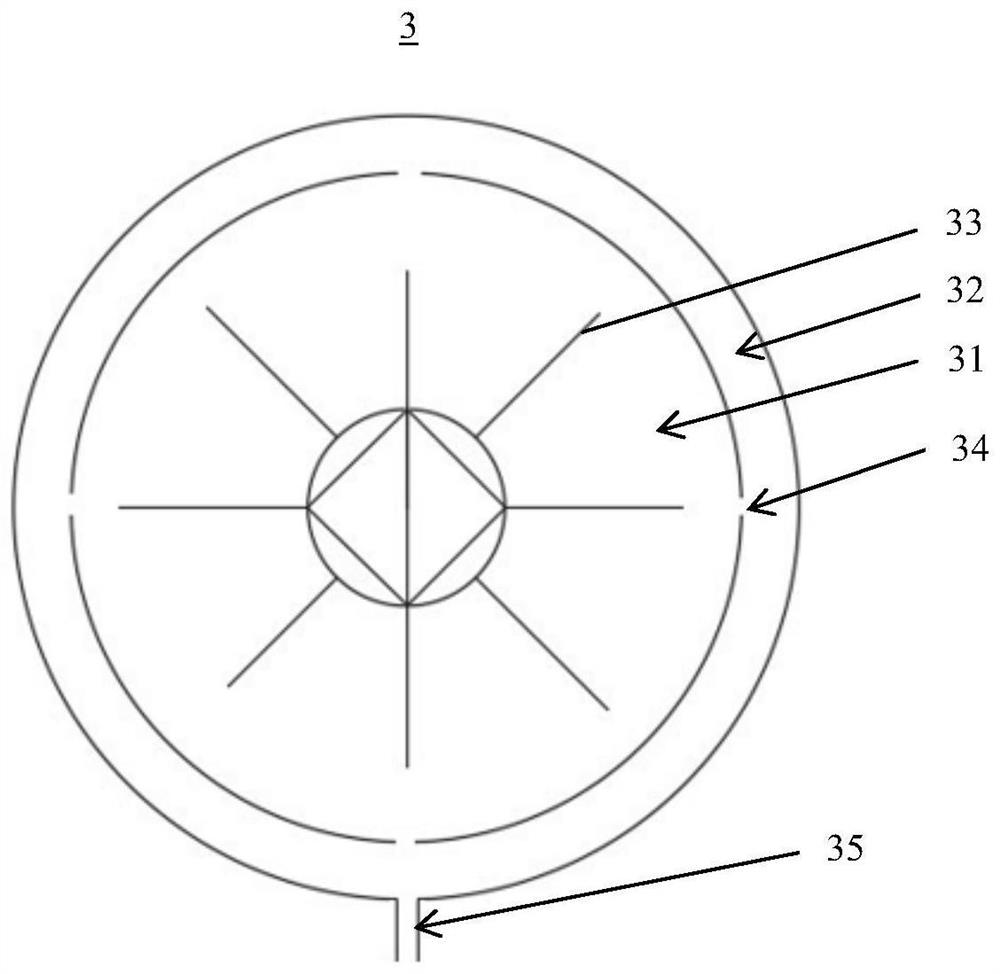

[0025] The preparation equipment 100 for the solid electrolyte membrane will be described below.

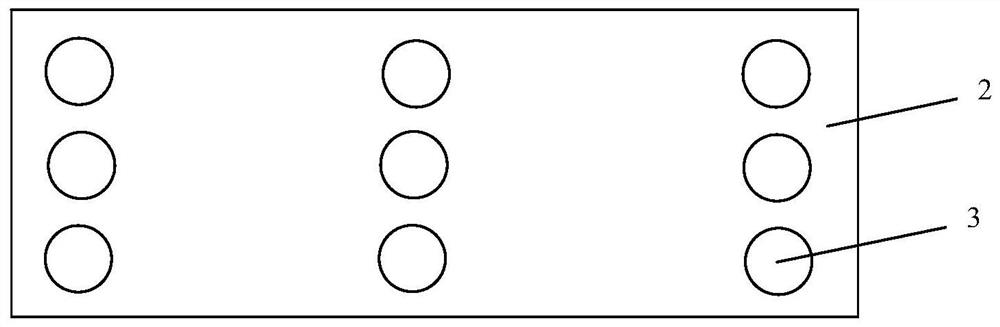

[0026] Such as Figure 1~2 As shown, the manufacturing equipment 100 of the solid electrolyte membrane includes a baking device 1 , several rotating shower heads 3 and a substrate 2 . The rotary spray head 3 is used to pressurize the solid electrolyte and spray it on the substrate 2, and the baking device 1 is used to dry the substrate 2 coated with the solid electrolyte, thereby forming a solid electrolyte film. A number of rotating spray heads 3 are installed in the baking device 1, and the substrate 2 passes through the baking device 1 and is continuously transported in the baking device 1, so that spraying and drying can be carried out simultaneously, and can be continuously sprayed and dried, improving the efficiency of spraying and drying. Dry efficiency, thereby effectively improving the preparation efficiency of solid electrolyte membranes. A number of rotating nozzles ...

Embodiment 1

[0040] The temperature of the baking device 1 is 100°C, the substrate 2 is polyethylene terephthalate PET, and the solid electrolyte material is polyethylene oxide (PEO). Figure 5 An example of the relationship between the transmission speed of different substrates 2 and the thickness of the solid electrolyte membrane is shown. As the transmission speed of the substrate 2 increases, the thickness of the solid electrolyte membrane decreases. Such as Figure 5 shown.

Embodiment 2

[0042] The temperature of the baking device 1 is 120°C, the substrate 2 is polyethylene terephthalate PET, and the solid electrolyte material is polyethylene oxide (PEO). Image 6 An example of the relationship between the transmission speed of different substrates 2 and the thickness of the solid electrolyte film is shown. As the transmission speed of the substrate 2 increases, the thickness of the solid electrolyte film decreases, as shown in Image 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com