Device and treatment method for deep purification treatment of mine water for production

A technology of deep purification and purification equipment, which is applied in the direction of mining wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of destroying the ecosystem, waste of water resources, and treatment standards that do not meet production requirements, and reduce labor intensity , save processing cost, improve the effect of primary purification quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

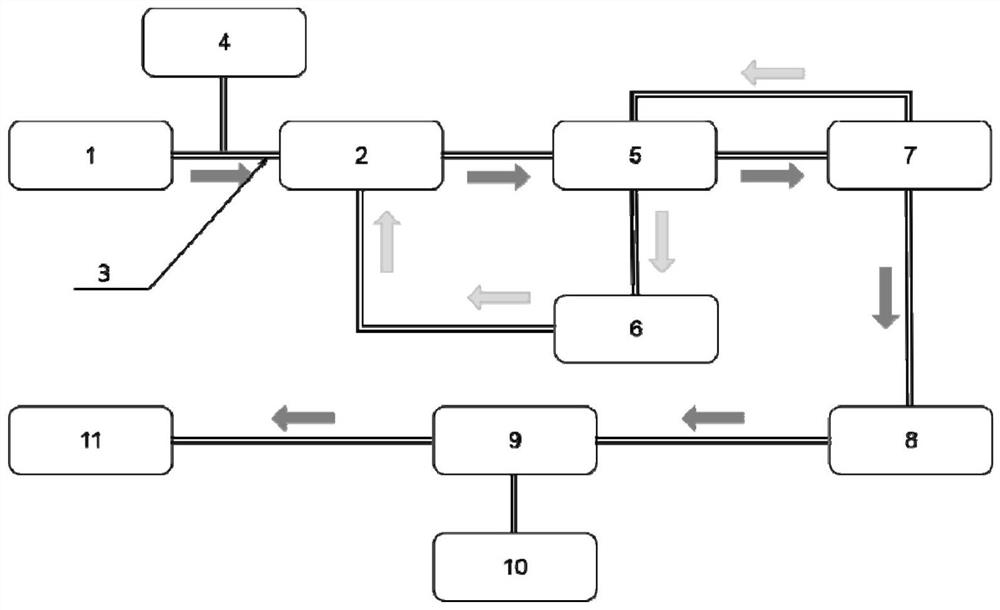

[0016] Embodiment 1: as attached figure 1 As shown, a device for deep purification treatment of mine water for production, which includes a ground water storage tank 1, a high-level primary sedimentation water storage adjustment tank 2, a reuse water tank 9 and an underground production water supply system 11, the ground water storage tank 1 The water pipe 3 is connected with the high-level primary sedimentation water storage adjustment tank 2, and the high-level primary sedimentation water storage adjustment tank 2 is connected with the multi-media filter 7 through the purification device 5, and the multi-media filter 7 passes through the membrane bioreactor 8 and the return The water tank 9 is connected to the underground production water supply system 11, and the automatic dosing device 4 is provided on the water delivery pipe 3.

[0017] Further, the device is also provided with a sodium hypochlorite generating device 10, and the sodium hypochlorite generating device 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com