Foamed silicone rubber core material and foamed heat-insulating buffer composite material

A technology of foamed silicone rubber and foamed heat insulation, which is applied in the field of foamed silicon rubber core materials and foamed heat insulation buffer composite materials, can solve the problem of not meeting the performance requirements of high-end products, flame retardant performance, and poor heat insulation performance Waiting for a question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

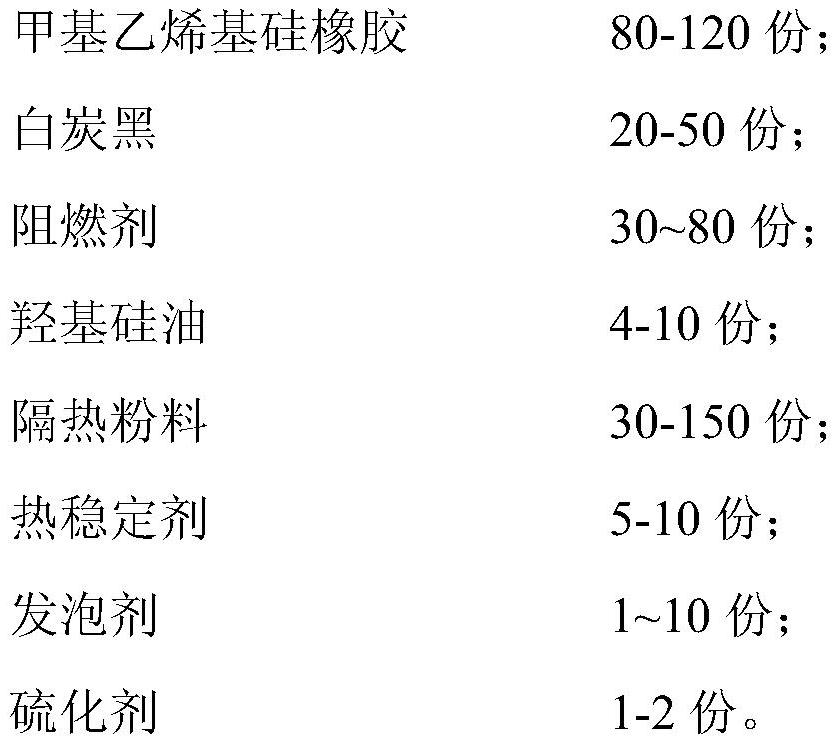

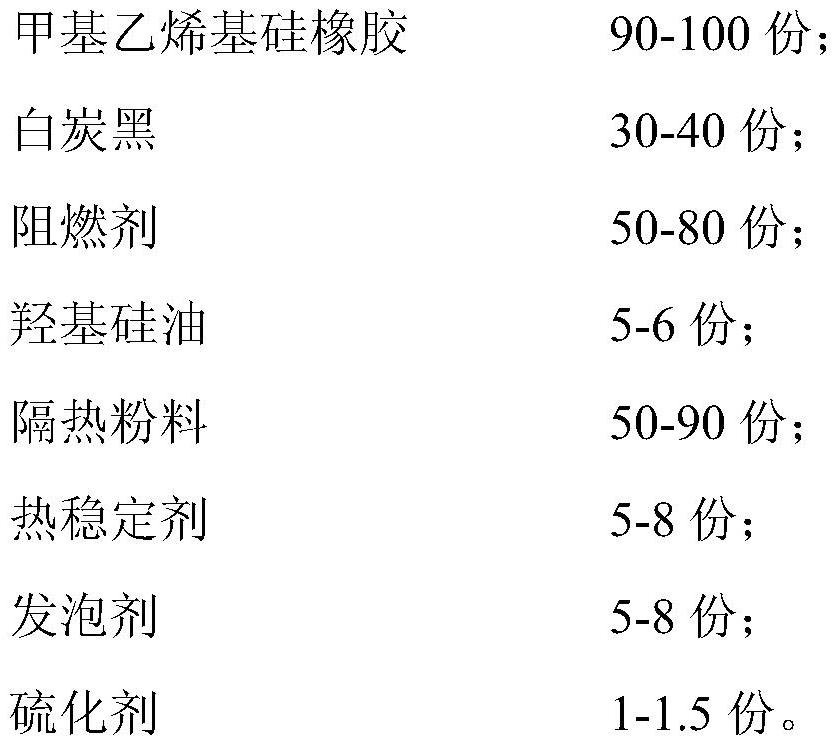

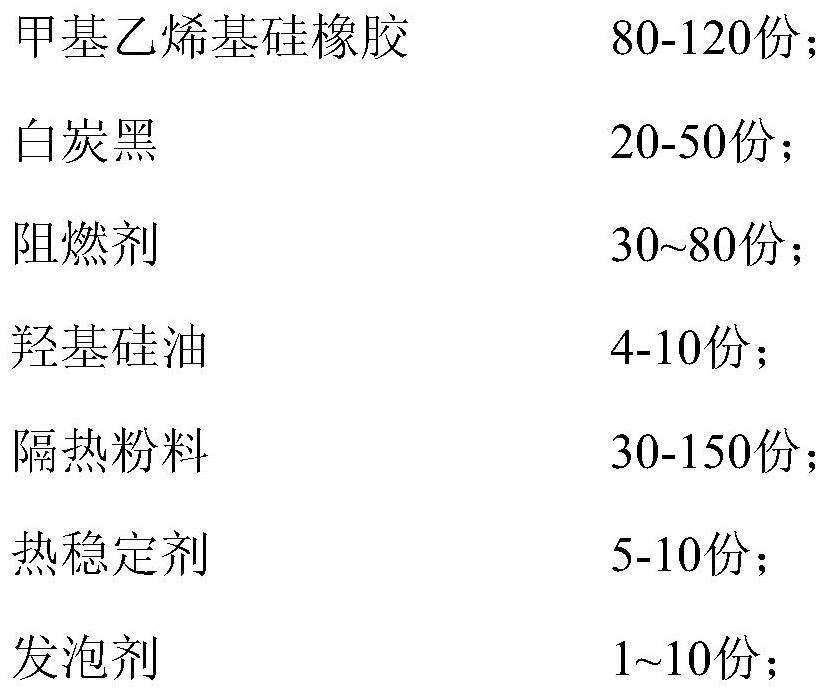

[0054] Another aspect of the present invention provides the preparation method of the foamed silicone rubber core material described in the first aspect of the present invention, the preparation method comprising: methyl vinyl silicone rubber, white carbon black, flame retardant, hydroxyl silicone oil, sea foam It is prepared by mixing stone, muscovite, wollastonite, heat stabilizer, foaming agent and vulcanizing agent.

[0055] In the preparation method of the foamed silicone rubber core material provided by the present invention, each raw material can be mixed according to the proportion provided by the first aspect of the present invention. Specifically, the flame retardant silicone rubber can be prepared by blending methyl vinyl silicone rubber, white carbon black, hydroxyl silicone oil, flame retardant, and heat stabilizer first. Then, muscovite is added to the flame-retardant silicone rubber, and the flame-retardant and heat-insulating silicone rubber is prepared by blen...

Embodiment 1

[0075]a. By adding 30 parts of white carbon black, 5 parts of hydroxyl silicone oil, 50 parts of silane-coated ammonium polyphosphate, 5 parts of zinc oxide, and 3 parts of titanium dioxide to 100 parts of methyl vinyl silicone rubber, the barrier is prepared by blending technology. Burn silicone rubber.

[0076] b. Add 50 parts of muscovite to flame-retardant silicone rubber, and prepare flame-retardant and heat-insulating silicone rubber by blending technology.

[0077] c. Add 3 parts of OBSH foaming agent, 5 parts of sodium bicarbonate, and 1 part of double 24 vulcanizing agent to the flame-retardant and heat-insulating silicone rubber, and mix well to obtain foamed flame-retardant and heat-insulating silicone rubber.

[0078] d. Through hot air foaming and vulcanization at a high temperature of 200-280 ° C, the foamed flame-retardant and heat-insulating silicone rubber is foamed and molded, and then processed into a foam core material of required size and specification.

...

Embodiment 2

[0081] a. By adding 30 parts of white carbon black, 5 parts of hydroxyl silicone oil, 50 parts of silane-coated ammonium polyphosphate, 5 parts of zinc oxide, and 3 parts of titanium dioxide to 100 parts of methyl vinyl silicone rubber, the barrier is prepared by blending technology. Burn silicone rubber.

[0082] b. Add 50 parts of sepiolite to flame-retardant silicone rubber, and prepare flame-retardant and heat-insulating silicone rubber by blending technology.

[0083] c. Add 3 parts of OBSH foaming agent, 5 parts of sodium bicarbonate, and 1 part of double 24 vulcanizing agent to the flame-retardant and heat-insulating silicone rubber, and mix well to obtain foamed flame-retardant and heat-insulating silicone rubber.

[0084] d. Through hot air foaming and vulcanization at a high temperature of 200-280 ° C, the foamed flame-retardant and heat-insulating silicone rubber is foamed and molded, and then processed into a foam core material of required size and specification. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com