Borate type automobile brake fluid

A technology of automobile brakes and borates, which is applied in the petroleum industry and lubricating compositions, etc., can solve the problems of borates being sensitive to water, easy to precipitate sediment, and large rubber expansion, so as to improve the anti-corrosion effect, High dry and wet boiling point, low temperature kinematic viscosity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

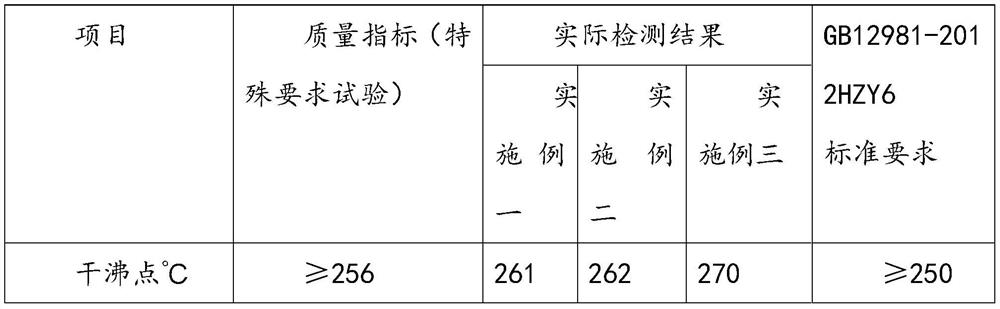

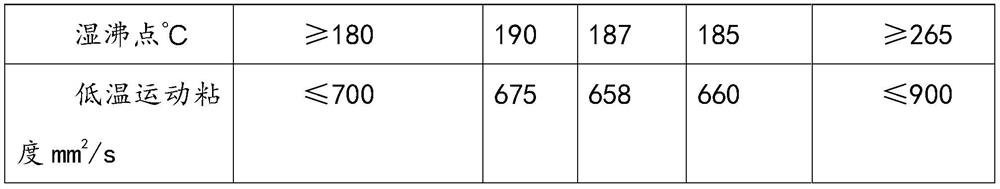

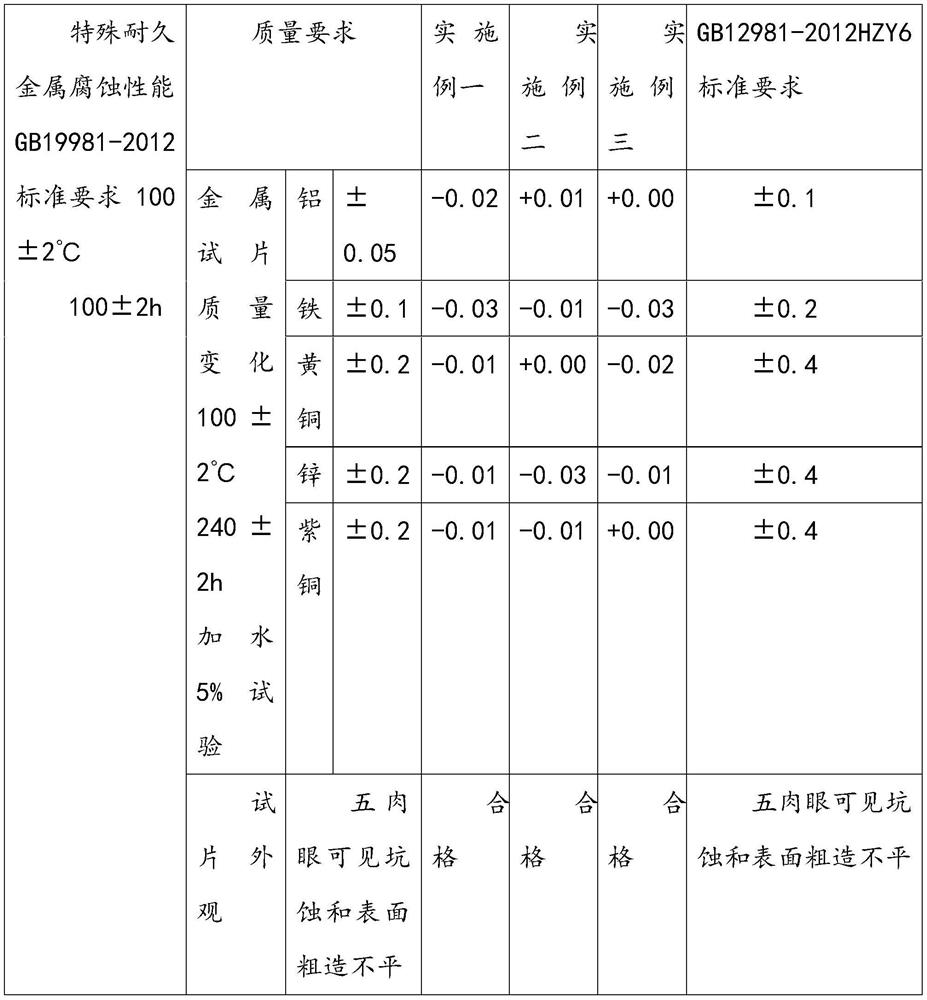

Embodiment 1

[0028] A borate-type automobile brake fluid, comprising the following raw materials in parts by weight: 60 parts of propylene glycol monomethyl ether borate, 3 parts of silicone oil, 10 parts of polyethylene glycol monoalkyl ether, triethylene glycol methyl ether Borate ester: 75 parts, 6-methyl-2-mercaptobenzothiazole: 0.2 part, antioxidant: 0.5 part, alkalinity regulator 1 part, corrosion inhibitor 1 part and metal preservative 0.1 part.

[0029] Further, the polyethylene glycol monoalkyl ether is at least one of the polyethylene glycol monoalkyl ethers shown by the molecular formula RO(CH2CH2O)nH, wherein R is an alkyl group with 1 to 6 carbon atoms, preferably It is CH3, CH3CH2, CH3CHCH3, CH3CH2CH2CH2, n is an integer of 2 or more, preferably 3, 4, or 5.

[0030] Further, the corrosion inhibitor is at least one of borax, sodium nitrite, oleic acid, and ricinoleic acid.

[0031] Further, the metal anti-corrosion agent is a combination of toluene, triazole and toluene, and ...

Embodiment 2

[0039] A borate-type automobile brake fluid, which is composed of the following raw materials in parts by weight: 65 parts of propylene glycol monomethyl ether borate, 5 parts of silicone oil, 25 parts of polyethylene glycol monoalkyl ether, triethylene glycol methyl Ether borate: 80 parts, 6-methyl-2-mercaptobenzothiazole: 0.5 part, antioxidant: 0.7 part, alkalinity regulator 2 parts, corrosion inhibitor 2 parts and metal preservative 0.2 part.

[0040] Further, the polyethylene glycol monoalkyl ether is at least one of the polyethylene glycol monoalkyl ethers shown by the molecular formula RO(CH2CH2O)nH, wherein R is an alkyl group with 1 to 6 carbon atoms, preferably It is CH3, CH3CH2, CH3CHCH3, CH3CH2CH2CH2, n is an integer of 2 or more, preferably 3, 4, or 5.

[0041] Further, the corrosion inhibitor is at least one of borax, sodium nitrite, oleic acid, and ricinoleic acid.

[0042] Further, the metal anti-corrosion agent is a combination of toluene, triazole and toluene...

Embodiment 3

[0050] 65 parts of propylene glycol monomethyl ether borate, 5 parts of silicone oil, 25 parts of polyethylene glycol monoalkyl ether, 80 parts of triethylene glycol monomethyl ether borate, 6-methyl-2-mercaptobenzothiazole: 0.5 parts, antioxidant: 0.7 parts, 2 parts of alkalinity regulator, 2 parts of corrosion inhibitor and 0.2 parts of metal preservative.

[0051] Further, the polyethylene glycol monoalkyl ether is at least one of the polyethylene glycol monoalkyl ethers shown by the molecular formula RO(CH2CH2O)nH, wherein R is an alkyl group with 1 to 6 carbon atoms, preferably It is CH3, CH3CH2, CH3CHCH3, CH3CH2CH2CH2, n is an integer of 2 or more, preferably 3, 4, or 5.

[0052] Further, the corrosion inhibitor is at least one of borax, sodium nitrite, oleic acid, and ricinoleic acid.

[0053] Further, the metal anti-corrosion agent is a combination of toluene, triazole and toluene, and its mass percentage is 1:5.

[0054] Further, the dry equilibrium reflux boiling p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com