Core tube type broken bridge composite wall system for low-energy-consumption building and construction method

A core tube, construction technology, applied in the direction of construction, building components, building structure, etc., can solve the problems of concrete fire protection layer and insulation layer falling off, life and property damage, high construction cost, to increase structural stability and safety. Seismic performance, solving the risk of cracking or falling off, and improving safety performance such as seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

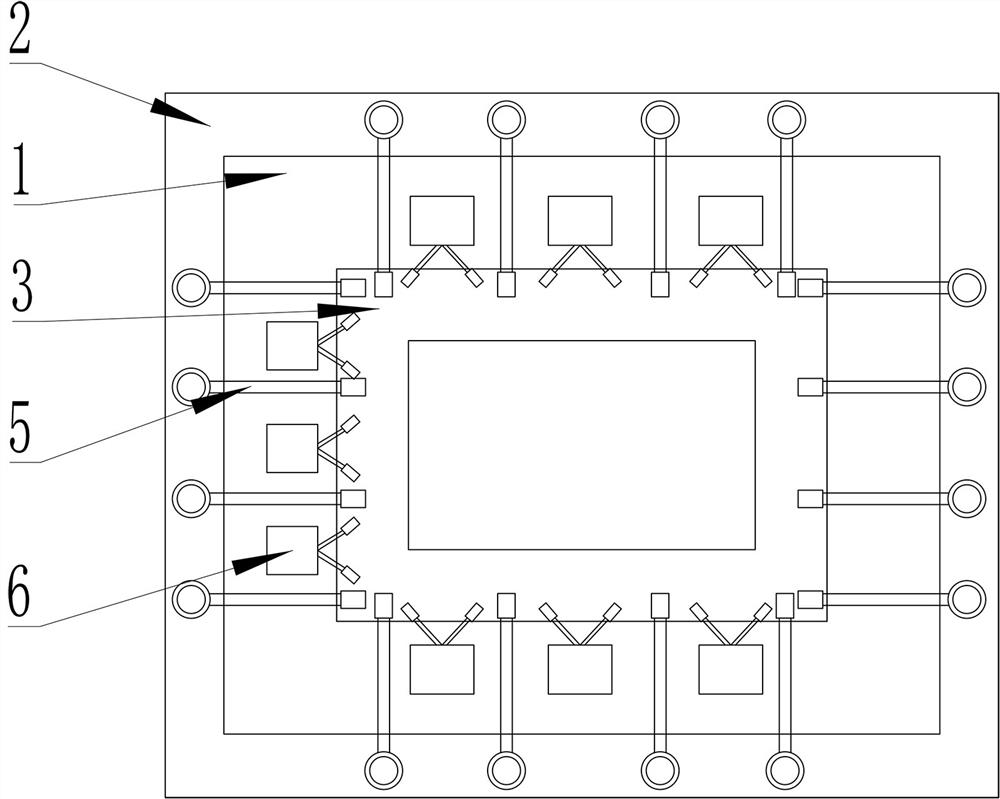

[0171] Such as Figure 13 As shown in part A in the middle, by adding a plurality of fixing pins 69 to connect the connecting cross bar 52 with the window sill rod 61, the whole door system is connected with the curtain wall system, which increases the shear resistance of the whole building. Due to the multiple fixing pins 69 is arranged inside the thermal insulation material, which will not produce cold and thermal bridges due to connection, and does not need to be broken bridges. While achieving the requirements of thermal insulation and low energy consumption, it has increased shear resistance compared to Example 1. The specifications and materials of the fixed pin 69 can refer to the connecting cross bar 52.

Embodiment 3

[0173] Such as Figure 13 In part B, Figure 14 As shown, the curtain wall system 6 includes an outer curtain wall system and an inner curtain wall system;

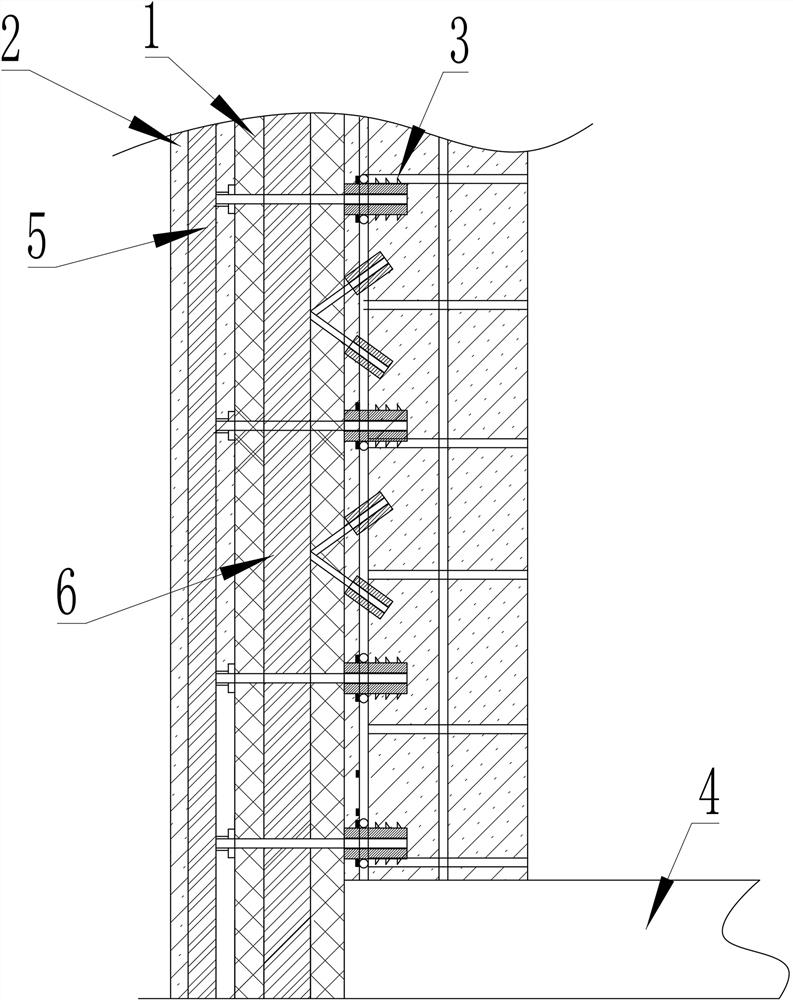

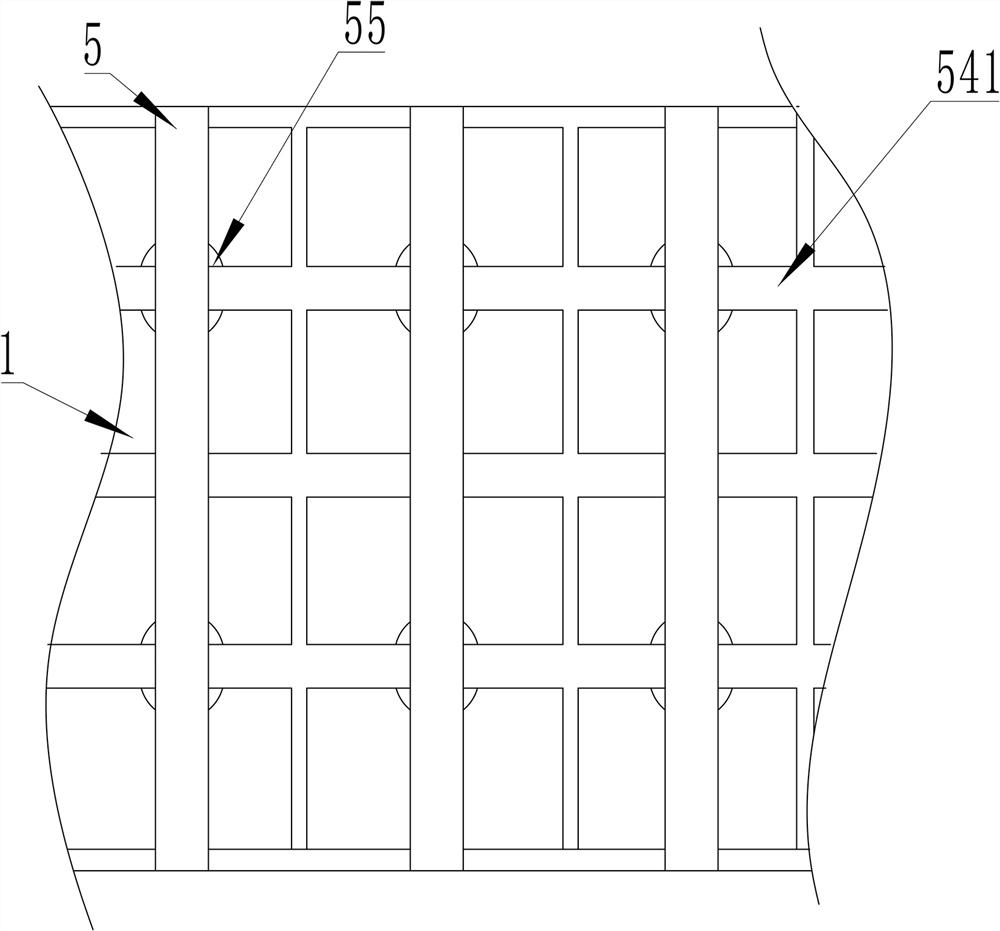

[0174] The inner curtain wall system is composed of a curtain wall structure connecting the prefabricated insulation board 1 and the main structure layer 3 of the concrete building from bottom to top; the curtain wall structure of the upper layer and the curtain wall structure of the lower layer are connected through a second connecting block 8 connections; the exterior curtain wall system includes a reinforced connector connecting the concrete fire protection shear protection layer 2 and the prefabricated insulation board 1; one end of the reinforced connector is connected to the window sill pole 61, and the other end is connected to the vertical Connect to pillar 51; Described reinforcing connector is reinforcing straight rod 66, by reinforcing straight rod 66, prefabricated insulation board 1 is connected with the con...

Embodiment 4

[0176] Such as Figure 13 , 15 As shown, the reinforcing connector can also be set as a reinforcing fork 67 arranged in the same form as the inner wire. The reinforcing fork 67 can be two forks or more than two forks that are evenly distributed in any direction in space. The reinforcing fork 67 Can be prefabricated in the prefabricated insulation board 1 in factory. The structure between the prefabricated insulation board 1 and the concrete fire protection shear protection layer 2 can form a triangular stable structure, which is beneficial to the lateral and horizontal force of the outer vertical pole 51 and the window sill pole 61, and is also conducive to the inclined force . Provide guarantee for the stability of the entire building.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com