Propeller and aircraft

A technology of propulsion and burner, applied in the field of aircraft, can solve the problems of poor heat dissipation energy, high working temperature of combustion chamber and turbine area, and small space of central axis, so as to achieve large power output coverage, reduce connection difficulty, and layout difficulty reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

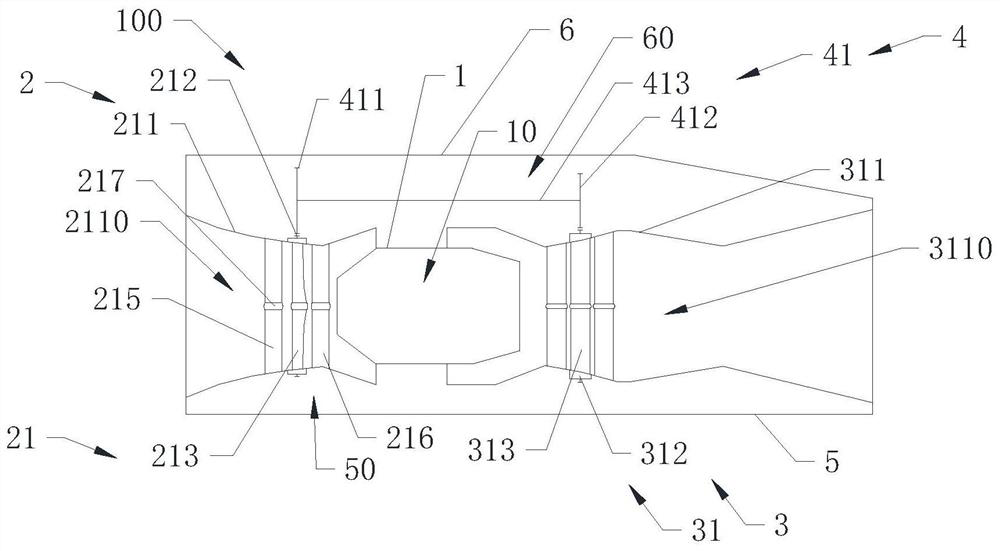

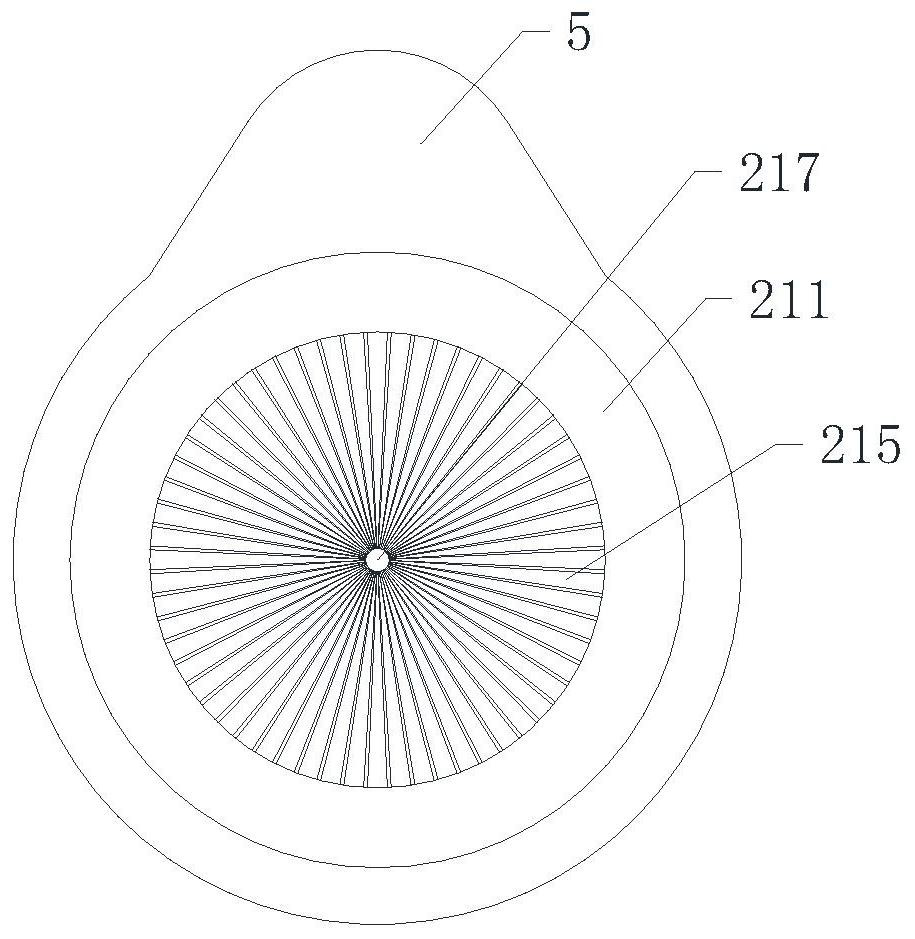

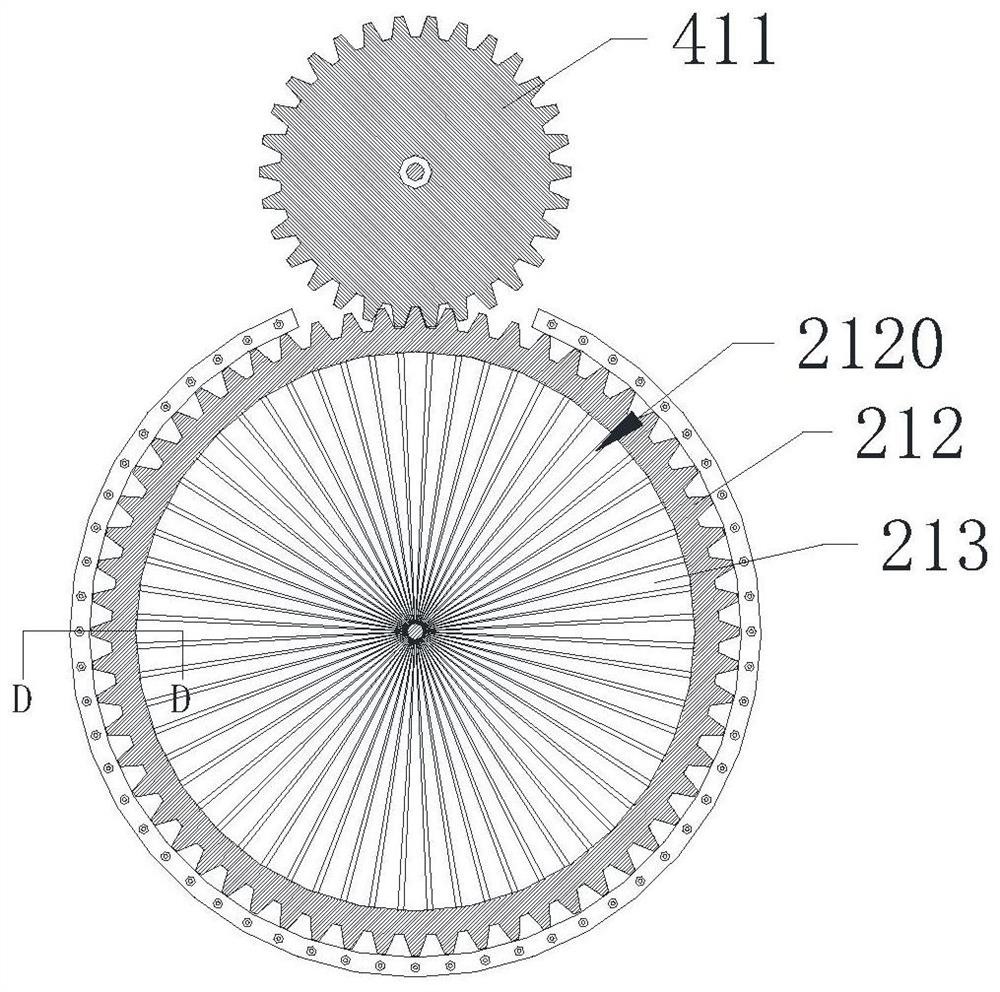

[0071] Reference manual attached Figure 1 to Figure 4 , the propeller 100 provided by the present invention is described. The propeller 100 uses shaftless blades instead of traditional shafted blades. The blade root is at the outer ring, and the root cross-sectional area and stiffness are greatly improved. When the compressor rotates at high speed, the huge centrifugal force generated by the blades generates pressure instead of pulling force at the blade root, which greatly reduces the difficulty of connecting the blade root and improves the fatigue performance at the blade root; the connecting sleeve can be installed at the central axis of the shaftless blade, Make the blades balance part of the centrifugal force in the form of tension between the blades, reduce the compressive stress at the root of the shaftless blade at the ring gear, and at the same time, the shaftless blades connected as a whole have higher stiffness in the airflow direction, so that the design and layout...

Embodiment 2

[0101] Reference manual attached Figure 5 , the second preferred embodiment of the propeller provided by the present invention is described, the structure of the propeller of the second preferred embodiment is basically the same as that of the first preferred embodiment, the difference is that in this In a preferred embodiment, the gas inlet mechanism 2 and the gas outlet mechanism 3 respectively have a multi-stage structure design.

[0102] Specifically, the gas inlet mechanism 2 includes a first air intake unit 221 , and the first air intake unit 221 includes more than one compressed air assembly 21 . Preferably, the first air intake unit 221 includes two compressed air assemblies 21 .

[0103] The gas discharge mechanism 3 includes a first exhaust unit 321 , and the first exhaust unit 321 includes more than one exhaust assembly 31 . Preferably, the first exhaust unit 321 includes one exhaust assembly 31 .

[0104] The transmission mechanism 4 includes a first transmissi...

Embodiment 3

[0120] Reference manual attached Figure 6A with Figure 6B , the third preferred embodiment of the propeller provided by the present invention is described, the structure of the propeller of the third preferred embodiment is substantially the same as that of the second preferred embodiment above, the difference is that in the third preferred In an embodiment, the gas discharge mechanism 3 further includes a power output unit 324, the gas discharged from the combustion chamber 10 can drive the power output unit 321 to work, and the power generated by the power output unit 324 can be transmitted to the outside of the thruster.

[0121] Specifically, the power output unit 324 includes more than one exhaust assembly 31, a power output shaft 324, and a power output gear 3242, wherein the power output gear 3242 is installed on one end of the power output shaft 3241, and the The power output gear 3242 meshes with the exhaust gear 312 of the exhaust assembly 31 of the power output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com