Rapid preparation method of Cu3Sn foamy copper composite joint for interconnection of 3D packaged laminated chip

A technology of composite joints and copper foam, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as stress concentration and limited thickness of micro-solder joints, achieve good mechanical properties, and meet mass use Requirements, the effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples, but the content of the present invention is not limited to the embodiments.

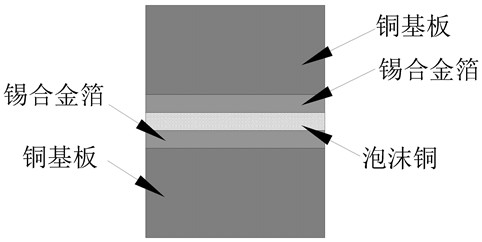

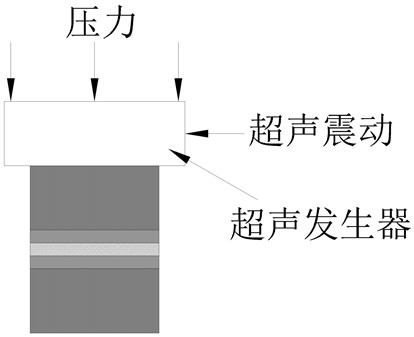

[0011] A kind of Cu for 3D packaging stacked chip interconnection 3 The rapid preparation method of Sn / foamed copper composite joint specifically comprises the following steps:

[0012] (1) Cleaning of foamed copper, tin alloy foil and copper substrate: commercial tin alloy (tin 99.3% copper 0.7%) foil (100μm), foamed copper (500ppi, 100μm) and copper substrate (1×1×0.5mm) Soak in acetone solution and ultrasonically clean for 5 minutes to remove oil stains on the surface of foamed copper, tin alloy foil and copper substrate; then soak the above foamed copper, tin alloy foil and copper substrate in 0.5% hydrochloric acid alcohol solution, ultrasonically cleaned for 5 minutes to remove surface oxides; then soak the above-mentioned foamed copper, tin alloy foil and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com