Deep ultraviolet LED with AlGaN/h-BN multi-quantum well structure and preparation method of deep ultraviolet LED

A multi-quantum well structure, multi-quantum well layer technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems affecting LED light output power, unbalanced electron and hole concentration, and low hole concentration. The growth process is simple and easy to operate, the effect of improving the hole injection difficulty and improving the hole injection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]In order to make the objects, technical solutions, and advantages of the present invention, the present invention will be further detailed in connection with the accompanying drawings. However, the invention can be implemented in different forms without interpreting embodiments of the embodiments set forth herein. Conversely, these embodiments will be made entirely and complete, and the scope of the invention is fully transmitted to those skilled in the art. In the drawings, for clarity, the dimensions of the layer and the region may be exaggerated, the same reference numerals are indicated by the same reference numerals from the beginning.

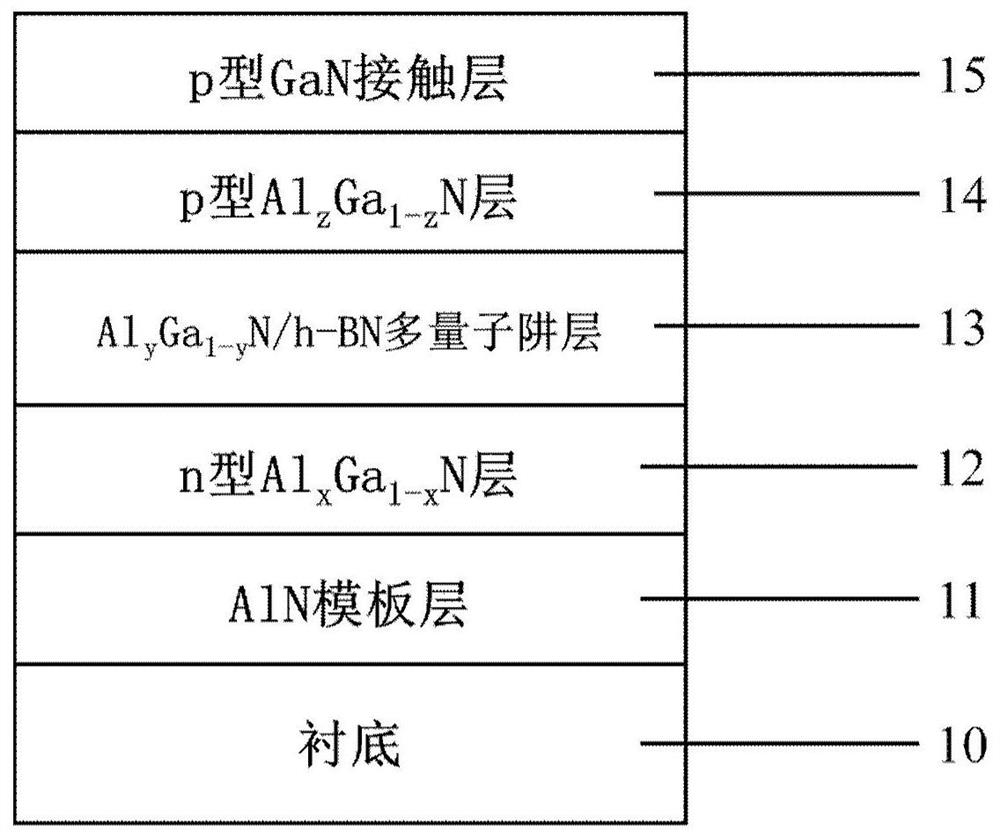

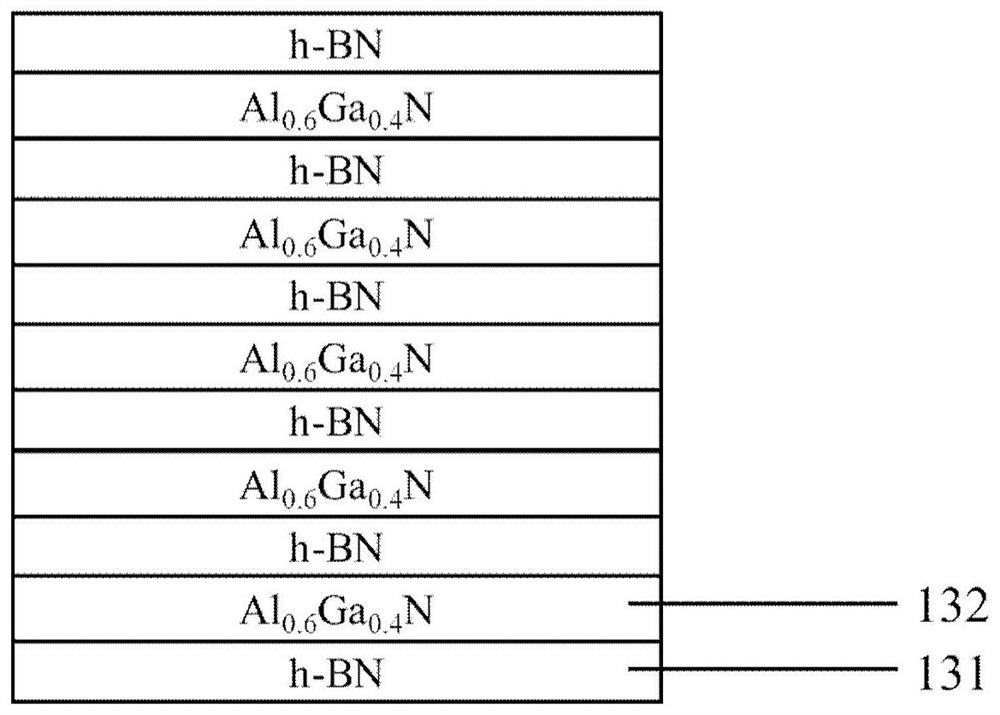

[0042] The present invention provides a deep ultraviolet LED of AlGaN / H-BN multi-quantum well structure, such as figure 1 As shown, from bottom to include: substrate 10, ALN template layer 11, n-type Al x GA 1-x N layer 12, al y GA 1-y N / H-BN multi-quantum well layer structure 13, P-type Al z GA 1-z The N layer 14, the P-type GaN c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com