System optimization process capable of improving compression effect of synthesis gas compressor and equipment thereof

A gas compressor and system optimization technology, which is applied in the field of synthesis gas preparation, can solve the problems of increased rotation speed and steam consumption, poor heat exchange effect of water cooler, and increased temperature of liquid ammonia at the outlet, so as to achieve long service life and reduce production. load, the effect of reducing steam energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

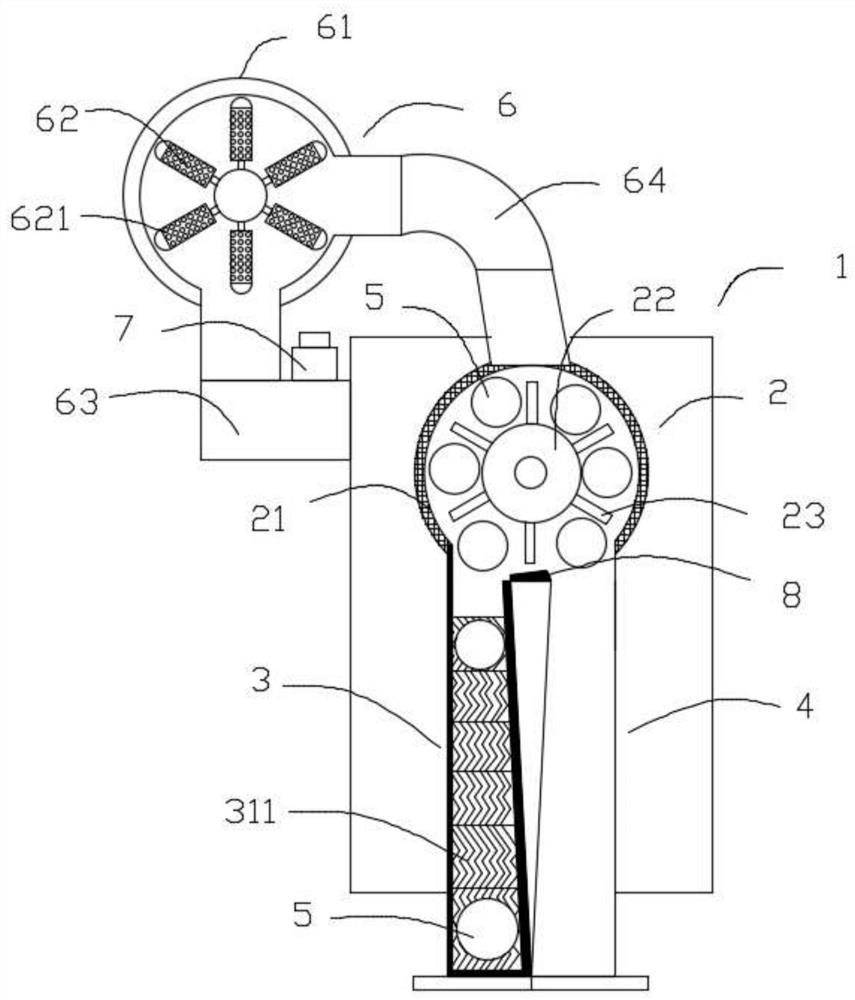

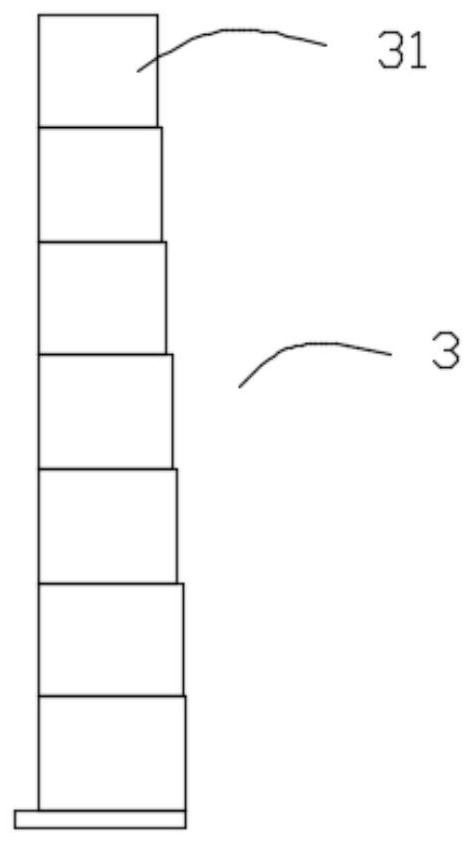

[0027] A system optimization process that improves the compression effect of synthetic gas compressors, mainly including the following steps:

[0028] S1, the preparation of the raw material gas

[0029] The syngas is from the boundary, and the synthesis gas compressor separation tank is passed through a cutout valve, and the pressure value of the separating gas compressor separation can exit is: 2500 kPa, so that the feed gas is separated by the synthesis gas compressor to separate the tank, its group Sub-volumes in the following range according to volume fraction: h 2 : 75%, N2 : 25%, while: CO + CO 2 + O 2 = 0.8ppmv, Ar + ch 4 = 1.6ppmv;

[0030] S2, syngas compression

[0031] The feeder air in S1 is incorporated into the centrifuge compressor in the synthesis gas synthesis tower, the centrifugal compressor supplies power through a steam turbine, and two surface coolers for different working load processing on the steam turbine. The ratio of the amount of insertion of nitrogen...

Embodiment 2

[0041] Unlike the embodiments

[0042] S1, the preparation of the raw material gas

[0043] The synthetic gas is from the boundary, and the synthesis gas compressor separation tank is passed through a cutout valve, and the pressure value of the separating gas compressor separation tank is controlled is: 2800 kPa, so that the feed gas is separated from the synthesis gas compressor to separate the tank, the group Sub-volumes in the following range according to volume fraction: h 2 : 75%, N 2 : 25%, while: CO + CO 2 + O 2 = 0.8ppmv, Ar + ch 4 = 1.6ppmv;

[0044] S2, syngas compression

[0045] The feeder air in S1 is incorporated into the centrifuge compressor in the synthesis gas synthesis tower, the centrifugal compressor supplies power through a steam turbine, and two surface coolers for different working load processing on the steam turbine. The ratio of the amount of insertion of nitrogen and hydrogen by bypass is: 3.3: 1 to the centrifugal compressor, the multi-stock gas is mix...

Embodiment 3

[0048] Different from the second embodiment

[0049] In S3, the line entering the first bed of the first bed is: First: the gas flows from the ammonia to the tower gap to the first catalyst bed heat exchanger to the first bed; the second: gas passes The strip cold wire flows into the first bed; Article 3: The gas flows through the second catalytic bed heat exchanger to the first bed; Article 4: The gas is started to the first bed of the first bed by the heater.

[0050] Through the use of one year and data record: The average value of the vacuum value in the synthetic gas compressor is: -83 kPa (g), and the average steam consumption of the compressor is: 74.58t / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com