A kind of pcvd lathe multi-channel rotary chuck

A rotary chuck, multi-channel technology, used in manufacturing tools, glass manufacturing equipment, etc., can solve the problems of inability to realize raw material transportation, high temperature gaseous raw material condensation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and examples.

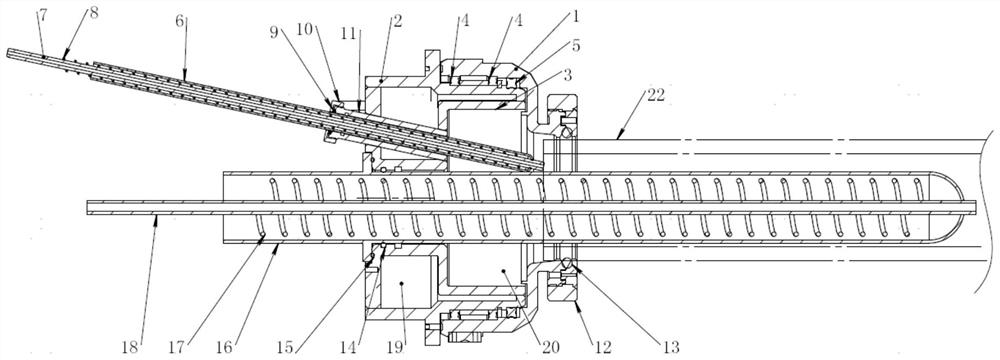

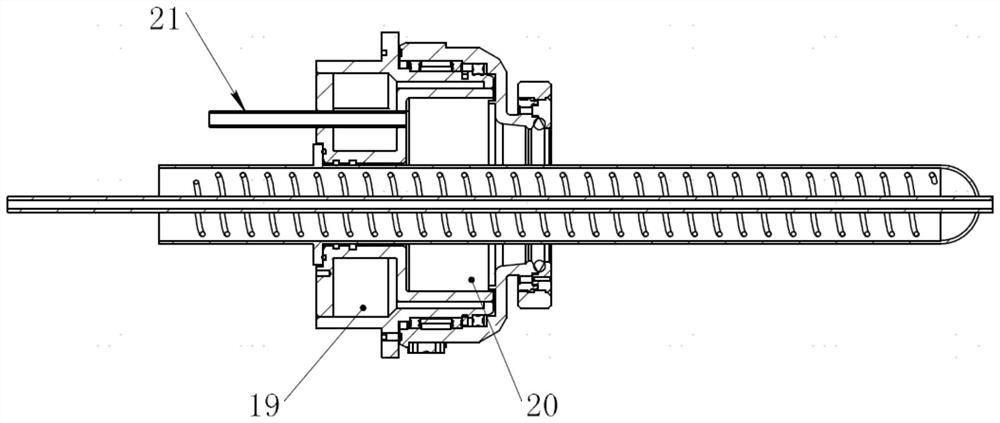

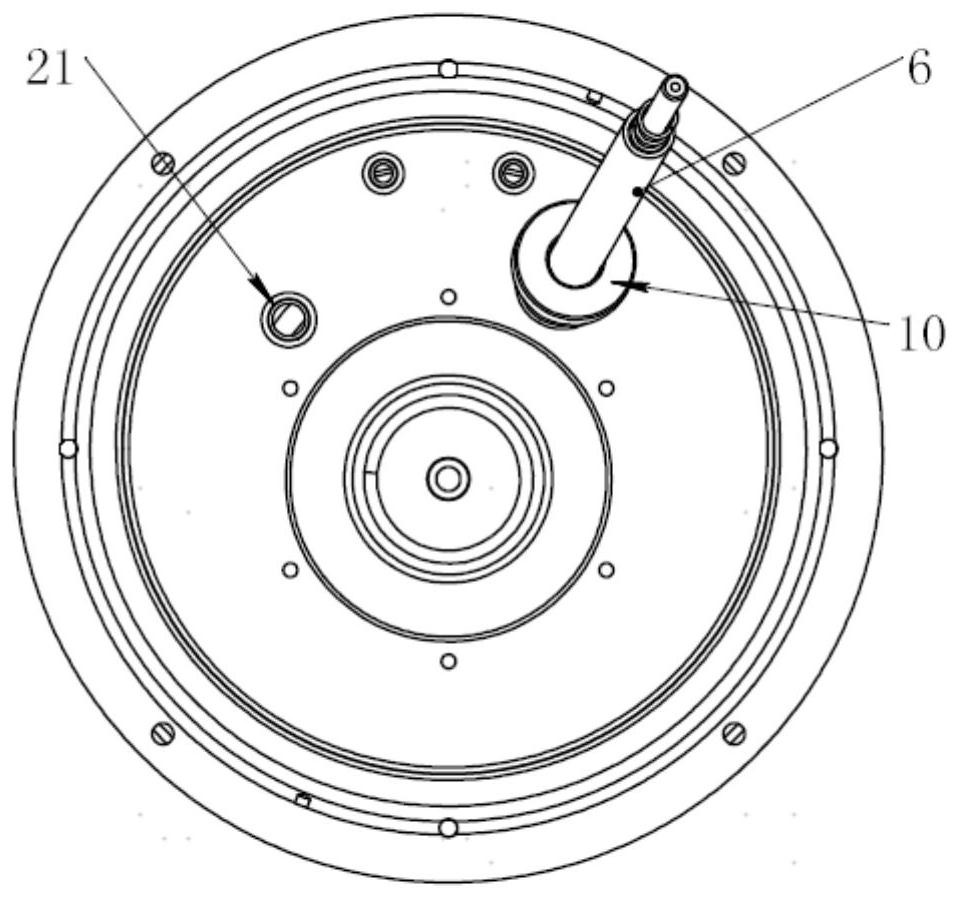

[0022] An implementation of the present invention Figure 1 ~ 4 As shown, including the fixing seat 2 and the rotary jacket 1, the fixing seat is connected to the PCVD lathe, and the front end of the holder is connected to the rotating jacket through the bearing 4, and there is a drive belt to rotate, the bearing is thin wall. The bearing is provided with a sealing device 5 between the fixing seat and the rotating jacket, the sealing device being an X-shaped seal, the front end shrink of the rotating jacket, a deposited liner, a deposition tube The front end of the clamp is equipped with the seal ring 13 and the lock nut 12 is configured to block the deposition liner with the rotating jacket. The front portion of the fixed seat is provided with a feed gas mixing chamber 20, and the substantially mixed feed gas pipe 21 is inserted into the fixed seat and the feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com