Ecological concrete water permeable brick based on fly ash lightweight aggregate and preparation method thereof

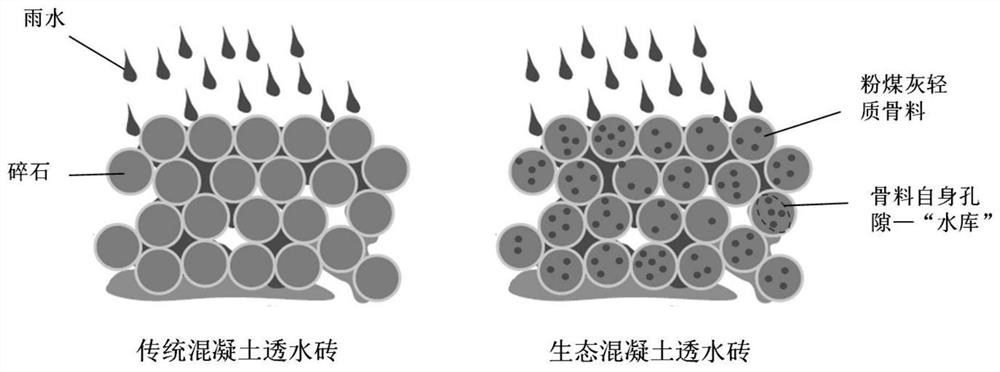

A technology of ecological concrete and lightweight aggregate, applied in the field of building materials, can solve the problems of ceramic permeable bricks, such as large energy consumption, large environmental damage, and limited water storage capacity, so as to alleviate the urban heat island effect, improve the living environment, and store water. strong water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An ecological concrete permeable brick based on fly ash lightweight aggregate is prepared by the following method:

[0040] (1) Preparation of fly ash lightweight aggregate. Prepare raw materials according to the ratio of raw materials: fly ash 80kg, blast furnace slag 20kg, water glass 16kg, water-cement ratio 0.35. Pour the fly ash and blast furnace slag into the cement slurry mixer and stir slowly for 1min. The slow speed is 140r / min for rotation and 62r / min for revolution. Mix the dry materials evenly; then, add alkaline The activator water glass and water, the water glass modulus is 2.18M, the Baume degree is 42 °, continue to stir at a slow speed for 2 minutes, stir at a high speed for 2 minutes, and stir at a speed of 285r / min for rotation and 125r / min for revolution, to obtain a uniformly mixed slurry; The slurry is cured at 50° C. for 24 hours, crushed and sieved to obtain particles of 2-10 mm, and the fly ash lightweight aggregate is obtained.

[0041](2) ...

Embodiment 2

[0045] An ecological concrete permeable brick based on fly ash lightweight aggregate is prepared by the following method:

[0046] (1) Preparation of fly ash lightweight aggregate. Prepare raw materials according to the ratio of raw materials: fly ash 75kg, blast furnace slag 25kg, water glass 20kg, water-cement ratio 0.38. Pour the fly ash and blast furnace slag into the cement slurry mixer and stir slowly for 1min. The slow speed is 140r / min for rotation and 62r / min for revolution. Mix the dry materials evenly; then, add alkaline The activator water glass and water, the water glass modulus is 2.2M, the Baume degree is 43 °, continue to stir at a slow speed for 2 minutes, stir at a rapid speed for 2 minutes, and stir at a speed of 285r / min for rotation and 125r / min for revolution to obtain a uniformly mixed slurry; The slurry was cured at 55°C for 24 hours, crushed and sieved to obtain particles of 2-10 mm, and the fly ash lightweight aggregate was obtained.

[0047] (2) Pr...

Embodiment 3

[0051] An ecological concrete permeable brick based on fly ash lightweight aggregate is prepared by the following method:

[0052] (1) Preparation of fly ash lightweight aggregate. Prepare raw materials according to the ratio of raw materials: fly ash 70kg, blast furnace slag 30kg, water glass 18kg, water-cement ratio 0.42. Pour the fly ash and blast furnace slag into the cement slurry mixer and stir slowly for 1min. The slow speed is 140r / min for rotation and 62r / min for revolution. Mix the dry materials evenly; then, add alkaline The activator water glass and water, the water glass modulus is 2.3M, the Baume degree is 44 °, continue to stir at a slow speed for 2 minutes, stir at a rapid speed for 2 minutes, and stir at a speed of 285r / min for rotation and 125r / min for revolution to obtain a uniformly mixed slurry; The slurry is cured at 60° C. for 24 hours, crushed and sieved to obtain particles of 2-10 mm, and the fly ash lightweight aggregate is obtained.

[0053] (2) Pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap