Polyimide precursor composition, polyimide film, laminated film and display device

A technology of polyimide precursor and polyimide film, which is applied in the field of polyimide precursor composition, polyimide film, laminated film and display device, can solve peeling, contamination of the inner wall of curing device, Low adhesion and other problems, achieve the effect of reducing CTE value, reducing escape amount, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

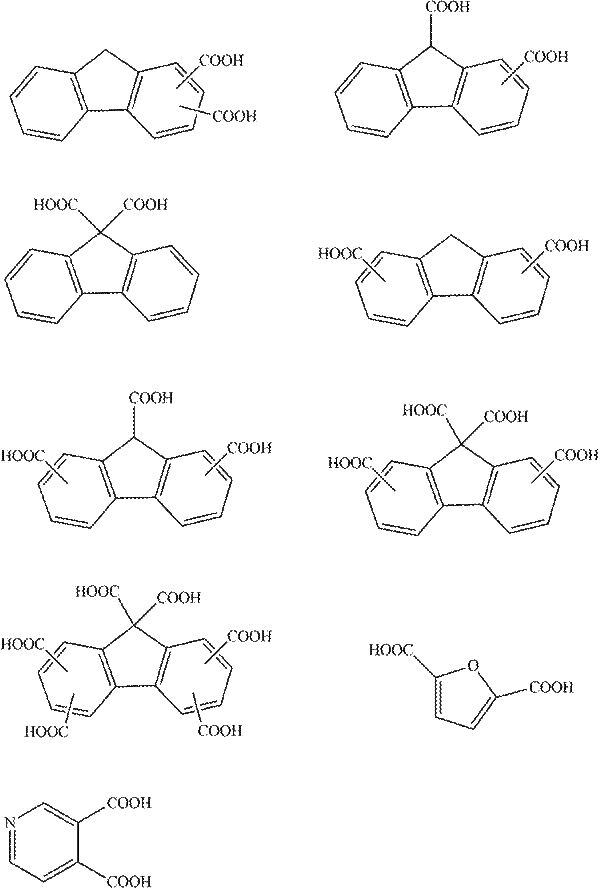

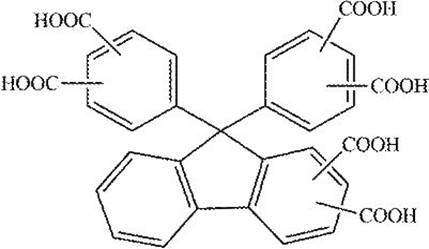

Method used

Image

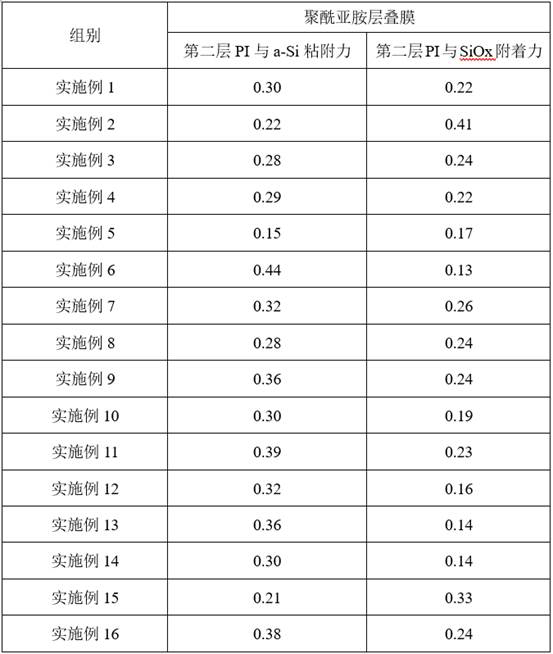

Examples

Embodiment 1

[0105] A three-necked flask of 1L was equipped with a mechanical stirrer, a spherical condensing tube and a nitrogen guide head. In the reaction flask, 233.00gNMP and 10.2733g PDA were dropped into. After the PDA was completely dissolved, 14.1226g BPDA was added in the reaction flask, and the mixture was then React at 60°C for 6 hours. Subsequently, the reaction temperature was reduced to 25 degrees Celsius, and 0.9913gMDA was added successively to the reaction solution. After the MDA was completely dissolved, 14.1226g BPDA, 1.2889g BTDA and 0.3183g [1,1',2',1 ' '-Triphenyl]-3,3''-dicarboxylic acid, after the completion of the feeding, polymerize at 25 degrees Celsius for 24 hours to obtain a polyimide precursor composition with a solid content of 15wt.%.

Embodiment 2

[0107] The three-necked flask of 1L is equipped with mechanical stirring, spherical condenser and nitrogen guide head, drops into 187.02gNMP and 10.2733g PDA in the reaction flask, after the PDA dissolves completely, then adds 14.1226g BPDA in the reaction flask, then the mixture is in React at 60°C for 6 hours. Then the reaction temperature was lowered to 25 degrees Celsius, and 0.9913g MDA was added to the reaction solution in sequence. After the MDA was completely dissolved, 14.1226g BPDA, 1.2889g BTDA and 0.2542g 9H-fluorene-9,9-dicarboxylate were added to the reaction flask Acid, after the completion of the feeding, polymerize at 25 degrees Celsius for 24 hours to obtain a polyimide precursor composition with a solid content of 18wt.%.

Embodiment 3

[0109] The three-necked flask of 1L is equipped with mechanical stirring, spherical condenser and nitrogen guide head, drops into 232.66gNMP and 10.2733g PDA in the reaction flask, after the PDA dissolves completely, then adds 14.1226g BPDA in the reaction flask, then the mixture is React at 60°C for 6 hours. Subsequently, the reaction temperature was reduced to 25 degrees Celsius, and 0.9913gMDA was added successively in the reaction solution. After the MDA was completely dissolved, 14.1226g BPDA, 1.2889g BTDA and 0.2582g 4-phenoxyphthalic acid were added to the reaction flask, After the feeding was completed, the polymerization reaction was carried out at 25 degrees Celsius for 24 hours to obtain a polyimide precursor composition with a solid content of 15 wt.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com