Method and device for cooling micro-channel semiconductor laser by high-speed gas carrying refrigerant

A high-speed gas and liquid refrigerant technology, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve problems such as high requirements for manufacturing processes, and achieve the effect of reducing junction temperature and high peak output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

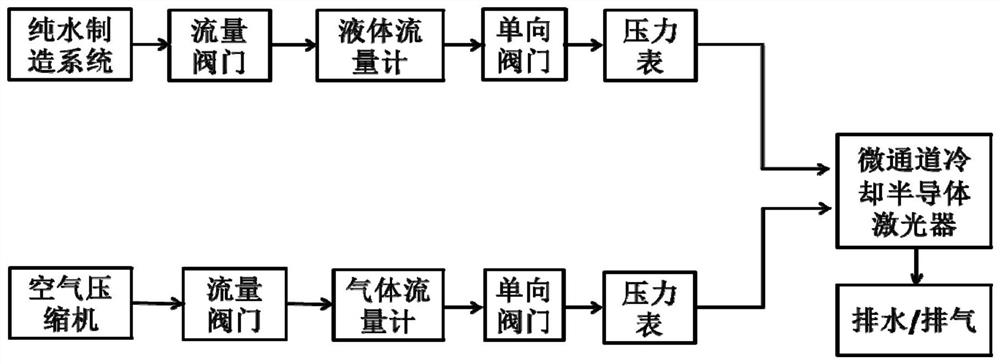

[0023] Below in conjunction with accompanying drawing, further describe the present invention in detail through embodiment.

[0024] The microchannel structure can effectively dissipate heat from the semiconductor laser chip due to its capillary distributed pipes. It is currently the most efficient packaging method for semiconductor lasers. For example, deionized water (thermal conductivity 0.6W / m*k) is used as liquid cooling The agent is circulated for heat dissipation. However, deionized water relies on the circulation of chillers, and is affected by pressure and flow, so it is difficult to achieve high-speed circulation and heat dissipation of micro-channel packaged semiconductor lasers.

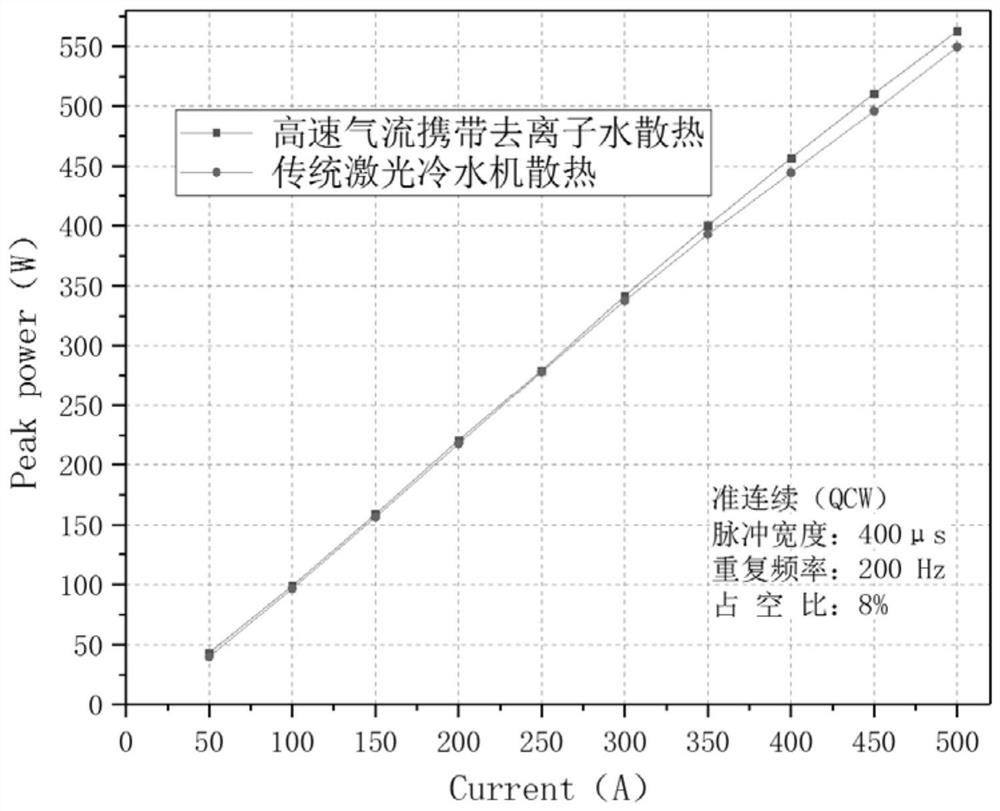

[0025] This embodiment proposes a method and device for cooling microchannel semiconductor lasers with high-speed gas carrying refrigerant. Although the thermal conductivity of air is low (0.026W / m*k), it combines the high speed of high-speed gas with the thermal conductivity of deionized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com