Carbon-based ferronickel bimetallic oxygen evolution catalyst and preparation method thereof

A carbon-based nickel-iron, bimetallic technology, applied in the field of carbon-based nickel-iron bimetallic oxygen evolution catalyst and its preparation, can solve the problems of poor catalytic oxygen evolution performance and stability, poor stability, and easy corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

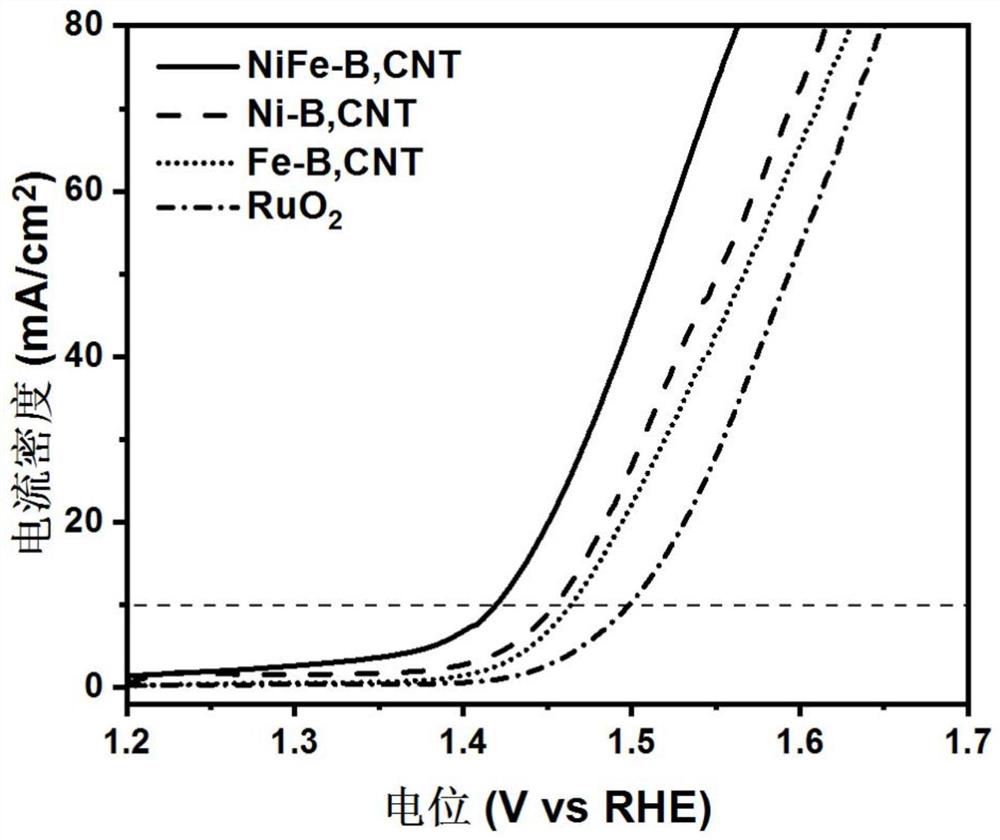

Examples

Embodiment 1

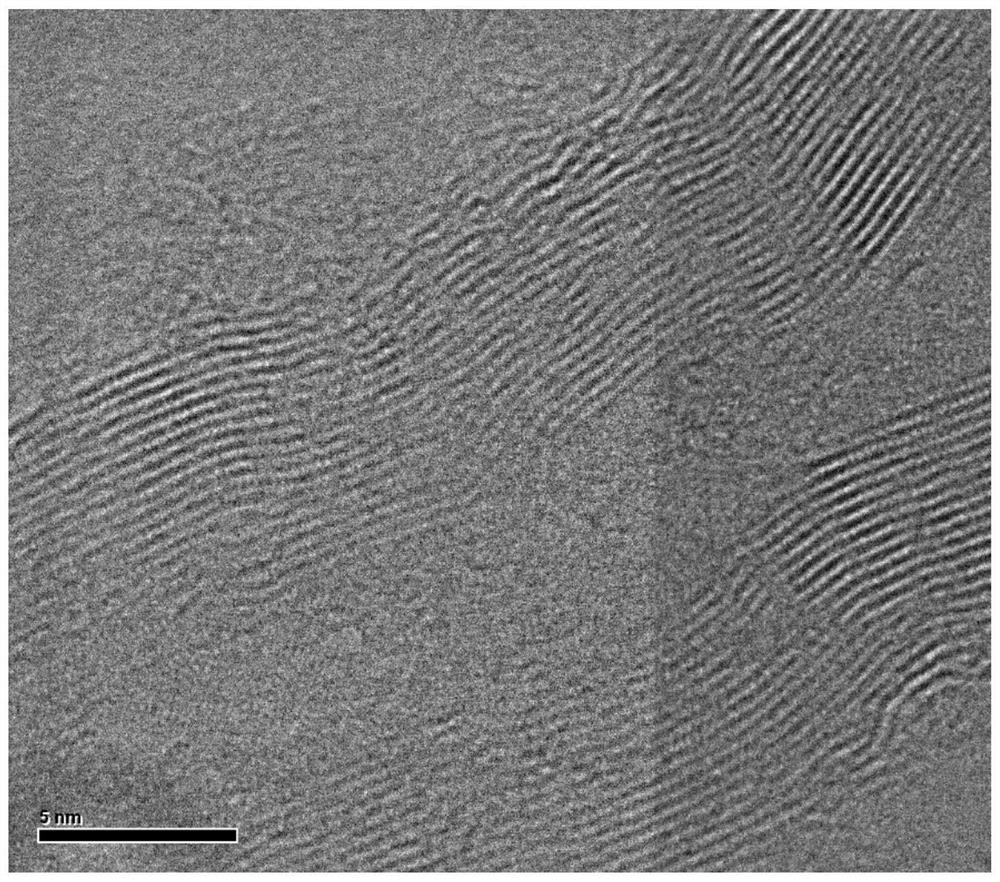

[0019] S1. Mix commercially available multi-walled carbon nanotubes and sodium tetraphenylborate in a mass ratio of 1:2, and mix them uniformly by ball milling to obtain a mixed powder.

[0020] S2. Put the mixed powder above in a ceramic ark, and raise the temperature from room temperature to 800° C. at a heating rate of 10° C. per minute under an argon atmosphere, and keep it warm for 4 hours to obtain borided carbon nanotubes.

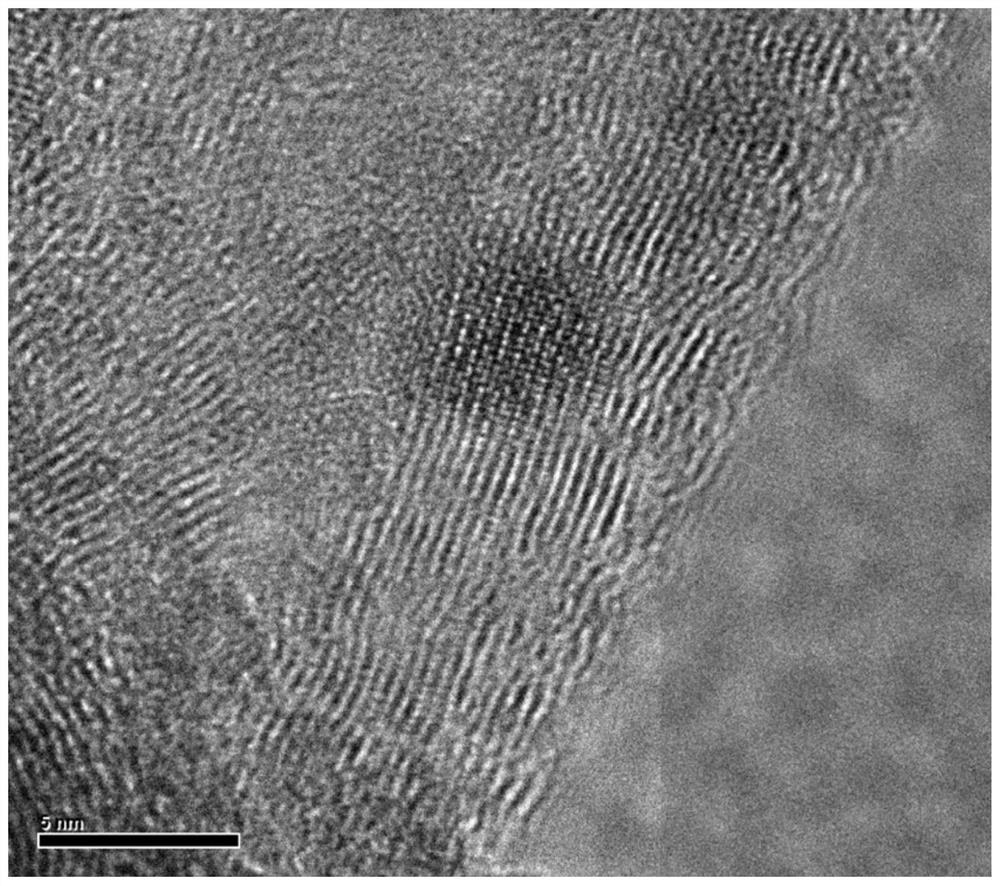

[0021] S3, get 10mg of borated carbon nanotubes and disperse them in 5mL water, then add 40wt% Ni(NO 3 ) 2 ·6H 2 O and 25wt% Fe(NO 3 ) 3 9H 2 O. Ultrasonic to make it completely dispersed, then continue to stir for 12h, and centrifuge the mixed material to obtain surface impregnated Ni 2+ and Fe 3+ The carbon nanotubes are dried to obtain the precursor powder of boride carbon nanotubes adsorbing nickel and iron.

[0022] S4. Heat the precursor powder in step 3 from room temperature to 380° C. at a rate of 10° C. per minute in an argon atmosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com