A kind of copper-doped ternary metal halide and preparation method thereof

A ternary metal, halide technology, applied in chemical instruments and methods, silver compounds, silver compounds, etc., can solve the problem of no fluorescence properties, and achieve the effect of improving fluorescence efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

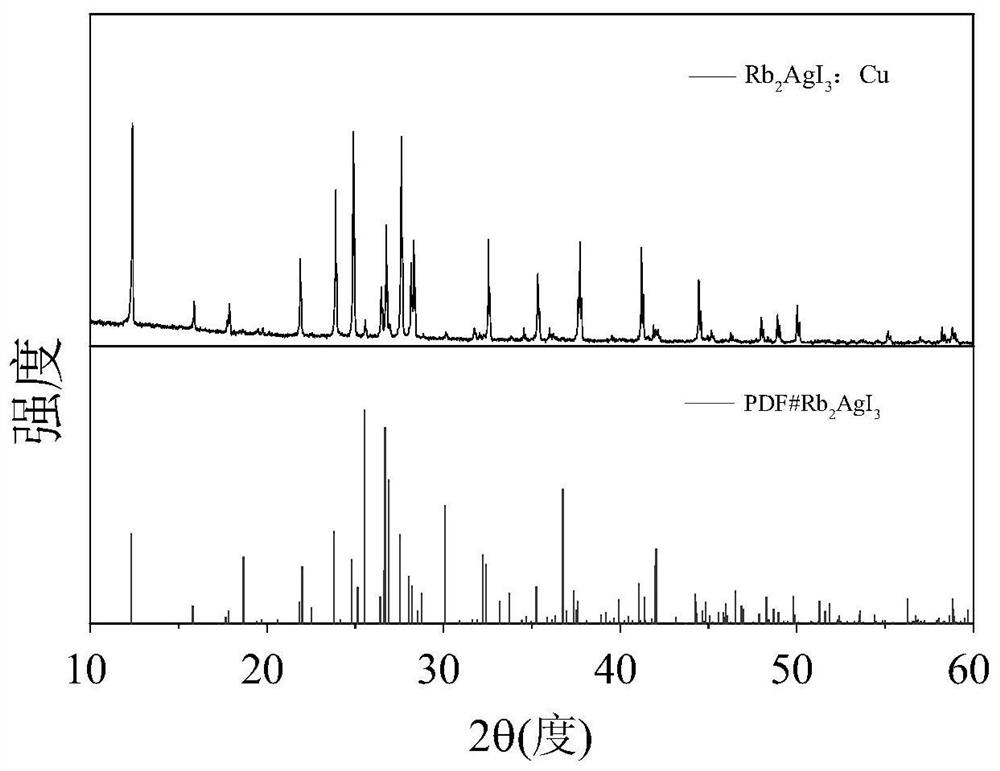

Embodiment 1

[0019] Weigh 2mmol rubidium iodide, 1mmol silver iodide, and 0.4mmol cuprous iodide in the glove box, pour them into a 25mL agate jar containing 25 agate balls with a diameter of 6mm, and take 30 microliters of H 3 PO 2 Put it into the grinding tank together with the reactants, set the AC frequency of the ball mill to 35Hz, and at this time the corresponding speed is 1050rad / min, mechanically grind for 15h, and the light yellow-green mixture powder changes from fluffy to dense with the prolongation of the grinding time, and finally becomes It becomes a fluffy white powder. After grinding, it is irradiated with an ultraviolet lamp with an excitation wavelength of 302nm. The product emits blue fluorescence. The product is further purified with ethanol, dried under vacuum at 45°C, and finally cooled at -10°C. After 1.5h, high-purity, bright blue fluorescent Rb was obtained 2 AgI 3 : Cu inorganic compound.

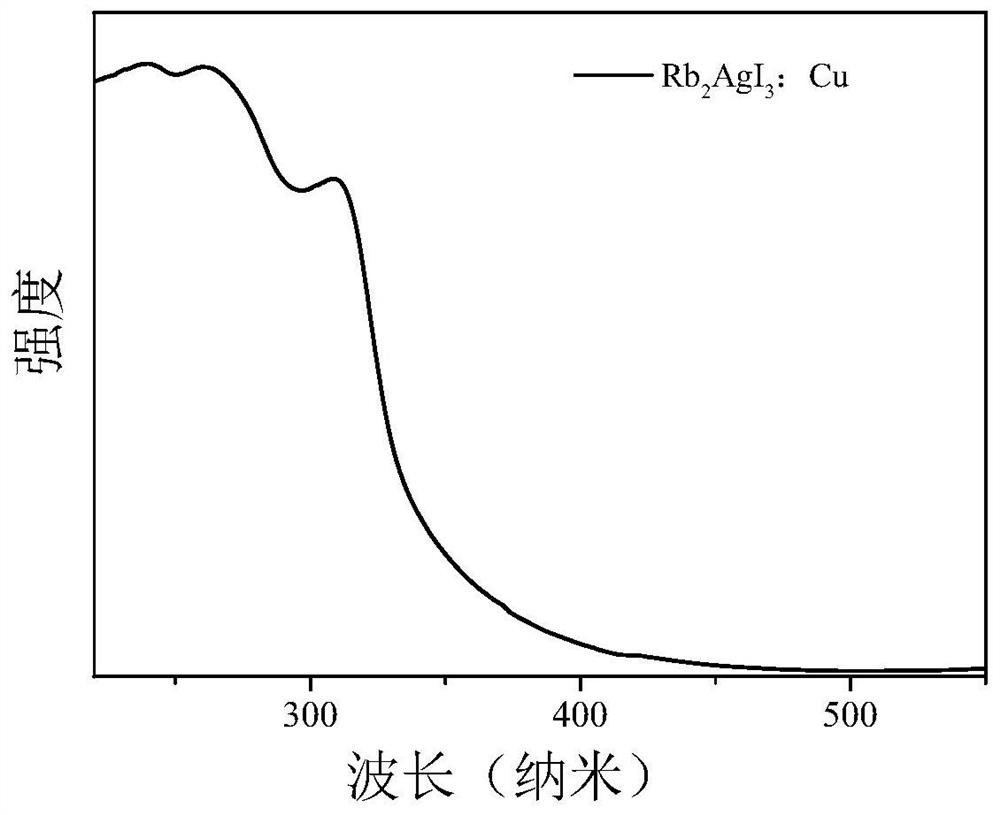

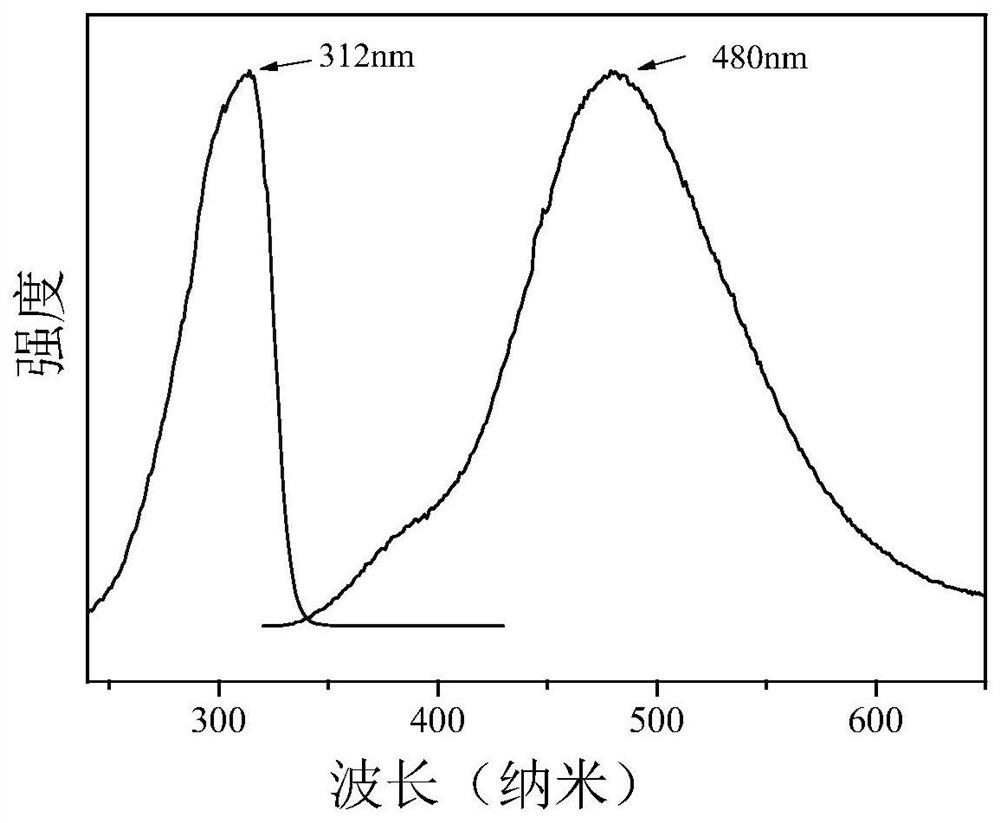

[0020] The product was tested for solid-state fluorescence excitation ...

Embodiment 2

[0022] In Example 1, due to Cu + Instability, disproportionation reaction easily occurs in acidic solution to form Cu 2+ And Cu, have an adverse effect on the fluorescence quantum yield of the product, so hypophosphorous acid must be added. The amount of hypophosphorous acid was changed from 30uL in Example 1 to 10uL, 20uL, and 50uL respectively, and other conditions and steps were unchanged. The fluorescence efficiency of each product was measured to be 49.1%, 49.8%, and 41.2%, respectively, so the amount of hypophosphorous acid was 30uL best.

Embodiment 3

[0024] In Example 1, the grinding time was too short to fully react the raw materials, and the pure phase of Rb could not be obtained. 2 AgI 3 , too long grinding time will cause Cs 3 CuI 5 The generation of impurity, so the grinding time must be appropriate. Change the grinding time from 15h to 2h, 10h, and 30h in Example 1, and find that grinding for 15h is pure phase Rb 2 AgI 3 : Cu, too short or too long grinding time will lead to the generation of impurity phases, the optimal grinding time is 15h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence quantum yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com