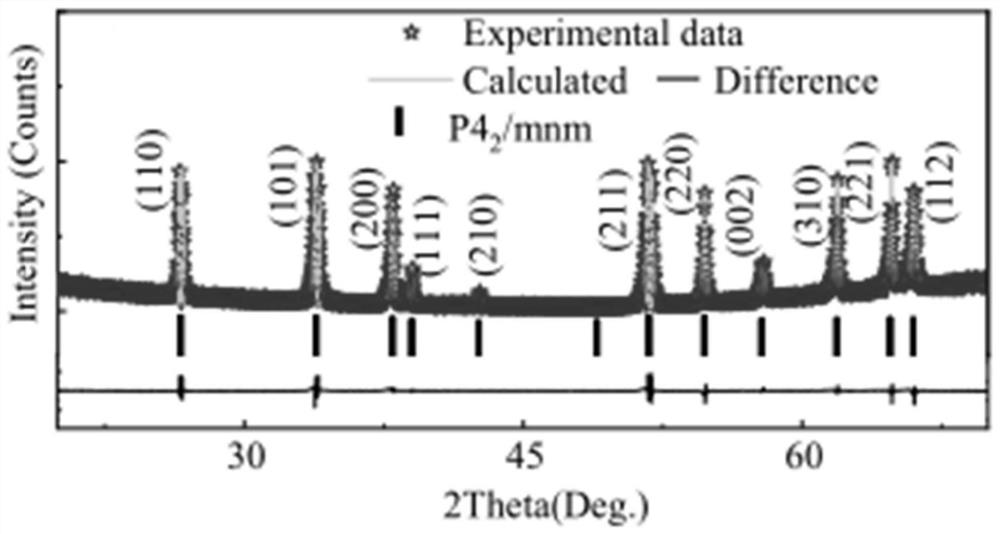

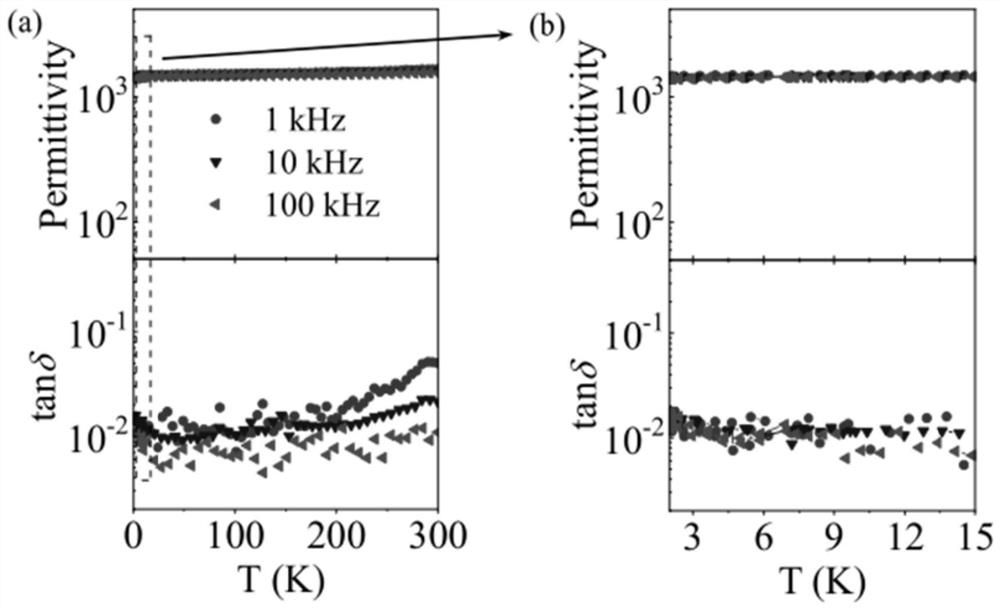

A low-temperature giant dielectric antiferromagnetic ceramic material and its preparation and application

A ceramic material and giant dielectric technology, applied in the field of low-temperature giant dielectric antiferromagnetic ceramic materials, to achieve low dielectric loss, excellent giant dielectric properties, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides the preparation method of the ceramic material, comprising the following steps: drying the ceramic powder composition, mixing it with a binder and granulating it, and then pressing it into a tablet to obtain a green embryo; The embryo is sintered after debinding at high temperature to obtain the ceramic material; the sintering temperature is 1300-1500°C.

[0032] In some embodiments, the ceramic powder is prepared according to the following steps:

[0033] (1) SnO 2 Powder, CoO powder, Ta 2 o 5 After the powder is weighed and mixed according to a certain molar ratio, it is put into a ball mill tank with zirconium balls as the medium with deionized water according to the mass ratio of 1-2:1, and ball milled with a planetary ball mill at a speed of 350-550 rpm 2 to 4 hours;

[0034] (2) Pour the ball-milled slurry into an enamel dish that has been cleaned in advance, and put it into an oven at 120°C for drying;

[0035] (3) Take ou...

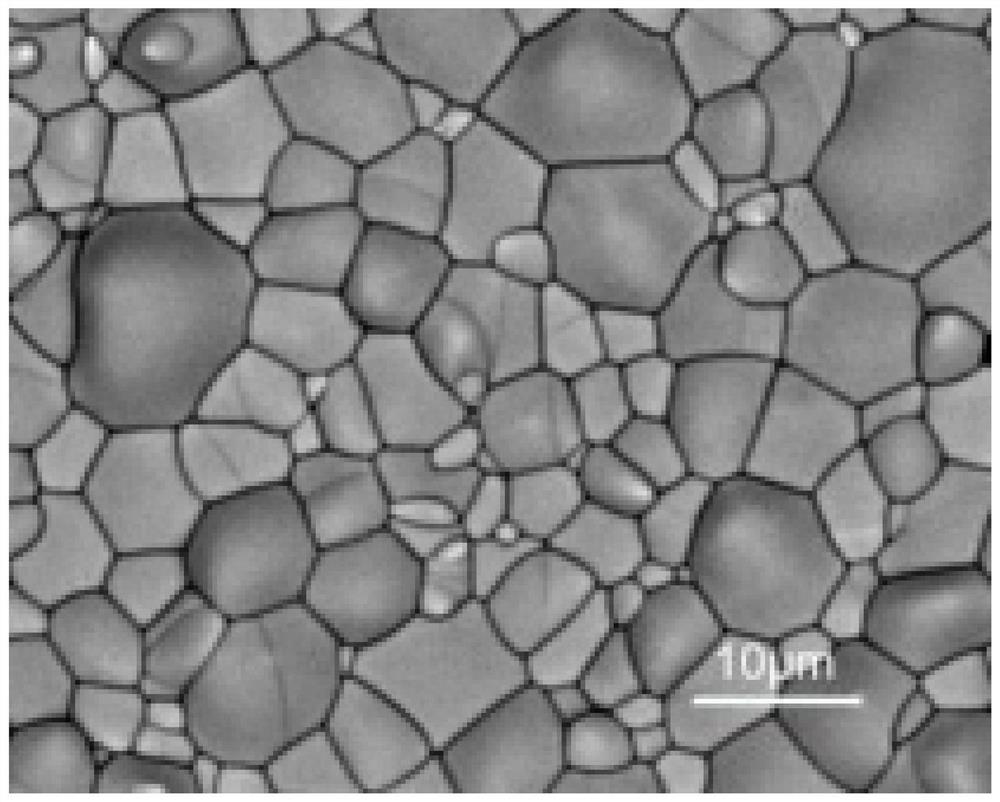

Embodiment 1

[0040] An ultra-low temperature giant dielectric antiferromagnetic SnO 2 The ceramic material is prepared according to the following method:

[0041] 1. Ingredients, drying, pre-burning

[0042] According to CoO: SnO 2=1.67%:98.33% molar ratio carries out compounding. Put the weighed material and deionized water into a ball mill tank with zirconium balls as the medium in a ratio of 3:2, and use a planetary ball mill to mill at a rate of 350 rpm for 3 hours; pour the milled slurry into Put it into the enamel dish that has been washed in advance, and dry it in an oven at 120°C.

[0043] 2. Granulation and dry pressing

[0044] Take out the dried powder and grind to make the powder thinner, then add 6wt% PVA (concentration is 8%) as binder, grind evenly again, cross 60 mesh sieves to obtain fine particles; The powder is pressed into a cylindrical green body with a diameter of 7 mm and a height of about 1 to 2 mm by using a 7 mm mold on a tablet press with a pressure of 100 M...

Embodiment 2

[0048] Basically the same as Example 1, the difference is that the ultra-low temperature giant dielectric antiferromagnetic SnO 2 The composition of ceramic materials varies, as follows:

[0049] The molar ratio of each component is: CoO: Ta 2 o 5 : SnO 2 = 1%: 1%: 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| antiferromagnetism | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com