Wide-load medium-pressure heat supply mode based on central regulating valve parameter regulation

A technology of adjusting gate parameters and load, which is applied in the field of cogeneration of thermal power generation. It can solve the problems of low power generation efficiency, high cost, and steam pressure and temperature that cannot meet the demand of small backpressure machines, and achieve the effect of improving flexibility and economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

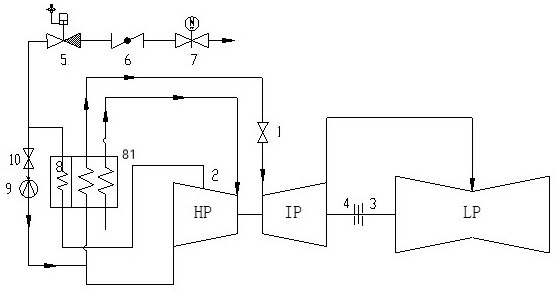

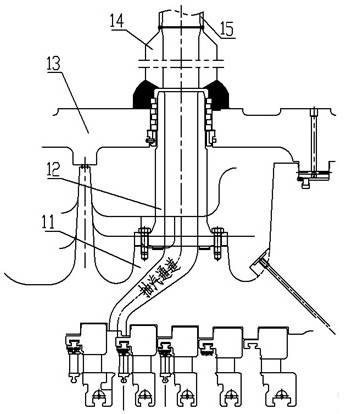

[0025] In this embodiment, a wide-load medium-voltage heating method based on the parameter adjustment of the central adjustment door is applied to thermal power generating units in power plants, such as figure 1 As shown, the heating system used in the medium-pressure heating mode of this embodiment includes a high-pressure cylinder, a medium-pressure cylinder, and a low-pressure cylinder connected in sequence. There is a thrust bearing between the medium-pressure cylinder and the low-pressure cylinder, and the thrust bearing is close to the middle The side of the pressure cylinder is the thrust bearing non-locating surface 4, and the side close to the low-pressure cylinder is the thrust bearing locating surface 3; the reheat steam outlet of the high-pressure cylinder is connected to the reheat cold section pipeline, and the reheat cold section pipeline is connected to the reheater 81 is connected to the steam inlet, the steam outlet of the reheater is connected to the reheati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com