Indoor assembly splicing type graphene heating floor

A graphene and splicing technology, which is applied in the field of assembled and spliced graphene heating floors, can solve problems such as difficult alignment and splicing, and achieve the effects of easy docking, good heating effect, and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

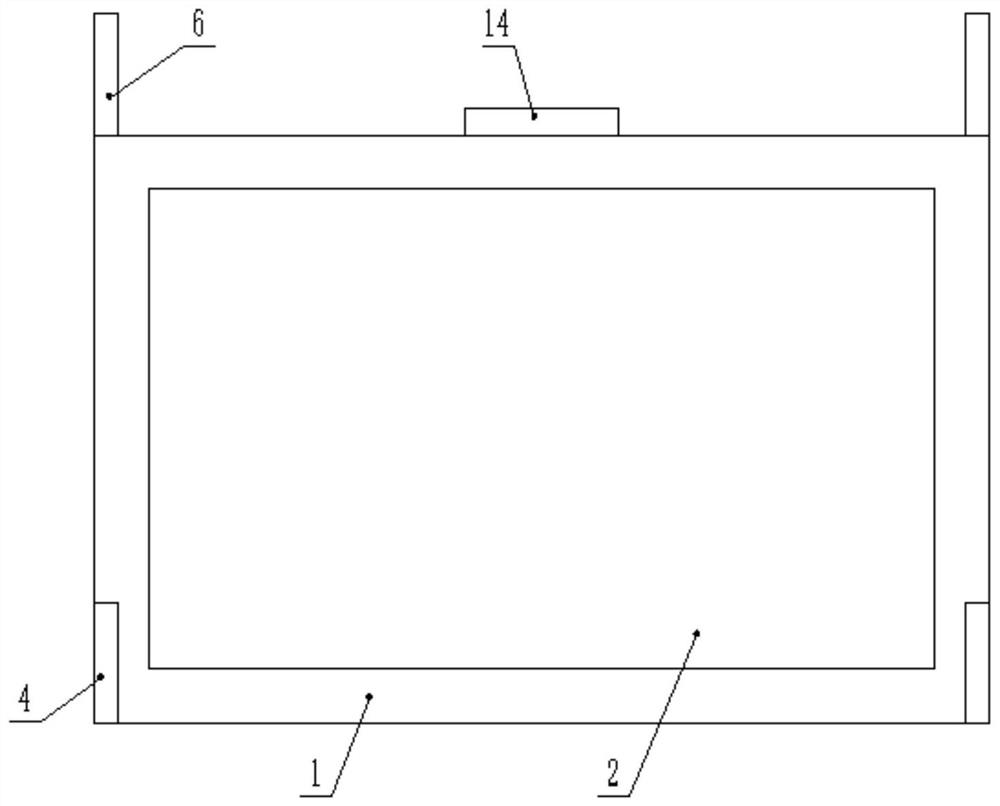

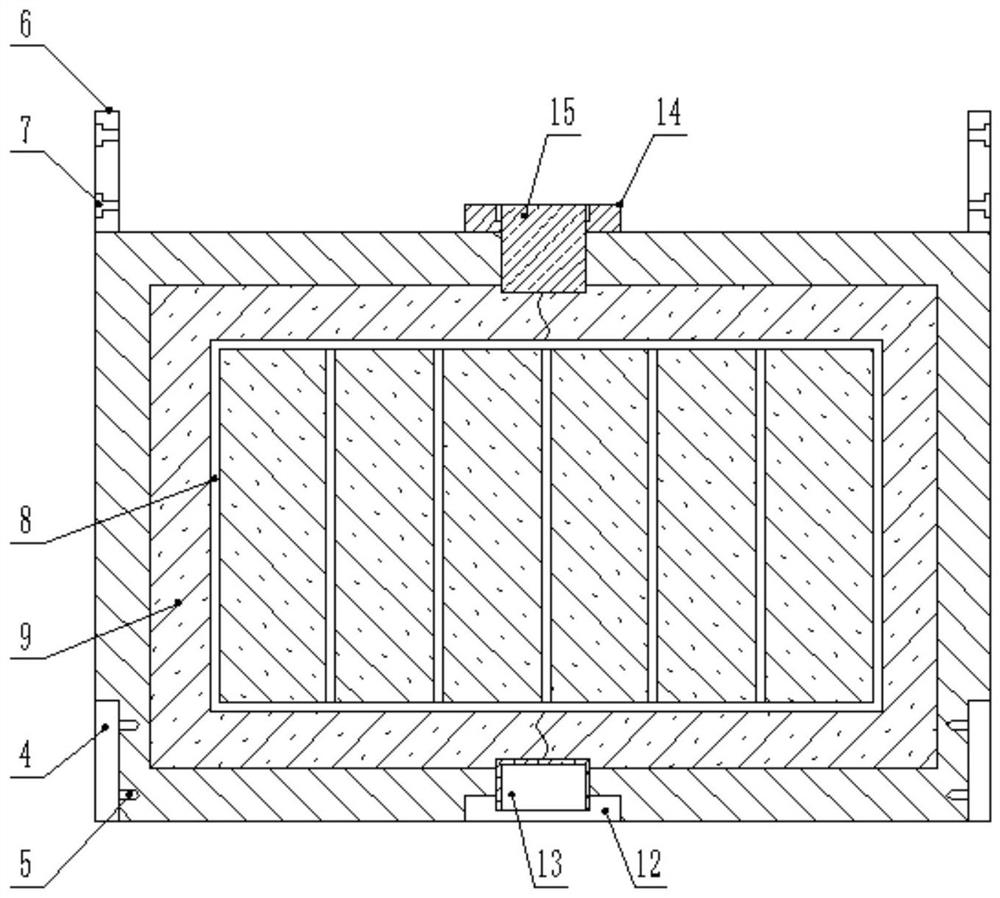

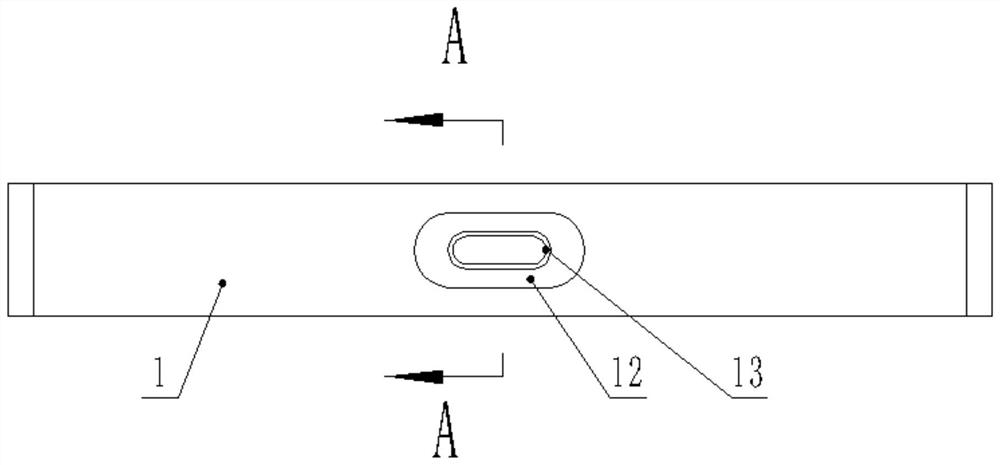

[0028] Example 1: Please refer to Figure 1-4 , an assembled and spliced graphene heating floor for indoor use, comprising a frame base 1, an upper sealing plate 2 and a lower sealing plate 3, the upper sealing plate 2 is fixedly connected to the upper side of the frame base 1, and the lower sealing plate 3 is fixedly connected to the frame On the lower side of the seat 1, there are notches 4 on the left and right sides of the frame seat 1, and the inner wall of the notch 4 is provided with threaded holes 5 arranged uniformly, and the rear side of the frame seat 1 is fixedly welded with a left-right symmetrical connecting plate 6. The plate 6 corresponds to the position of the notch 4, and the connecting plate 6 is provided with a counterbore 7, which matches the position of the threaded hole 5, and a heating grid 8 is arranged between the upper sealing plate 2 and the lower sealing plate 3, A filling layer 9 is provided outside the heating grid 8, a heat conducting layer 10...

Embodiment 2

[0037] Embodiment Two: This embodiment is further described as the previous embodiment: please refer to Figure 1-4 , an assembled and spliced graphene heating floor for indoor use, comprising a frame base 1, an upper sealing plate 2 and a lower sealing plate 3, the upper sealing plate 2 is fixedly connected to the upper side of the frame base 1, and the lower sealing plate 3 is fixedly connected to the frame On the lower side of the seat 1, there are notches 4 on the left and right sides of the frame seat 1, and the inner wall of the notch 4 is provided with threaded holes 5 arranged uniformly, and the rear side of the frame seat 1 is fixedly welded with a left-right symmetrical connecting plate 6. The plate 6 corresponds to the position of the notch 4, and the connecting plate 6 is provided with a counterbore 7, which matches the position of the threaded hole 5, and a heating grid 8 is arranged between the upper sealing plate 2 and the lower sealing plate 3, A filling laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com