Continuous flowing method for measuring content of calcium carbonate in cigarette paper

A technology of calcium carbonate and cigarette paper, which is applied in the preparation of test samples, material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions can solve problems such as deviations in test results and achieve The effect of improving the range, the method is simple, and the prospect of good application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1——Detection of calcium carbonate content in cigarette paper base.

[0038] 1. Experimental principle, materials and methods

[0039] 1.1 Experimental principle

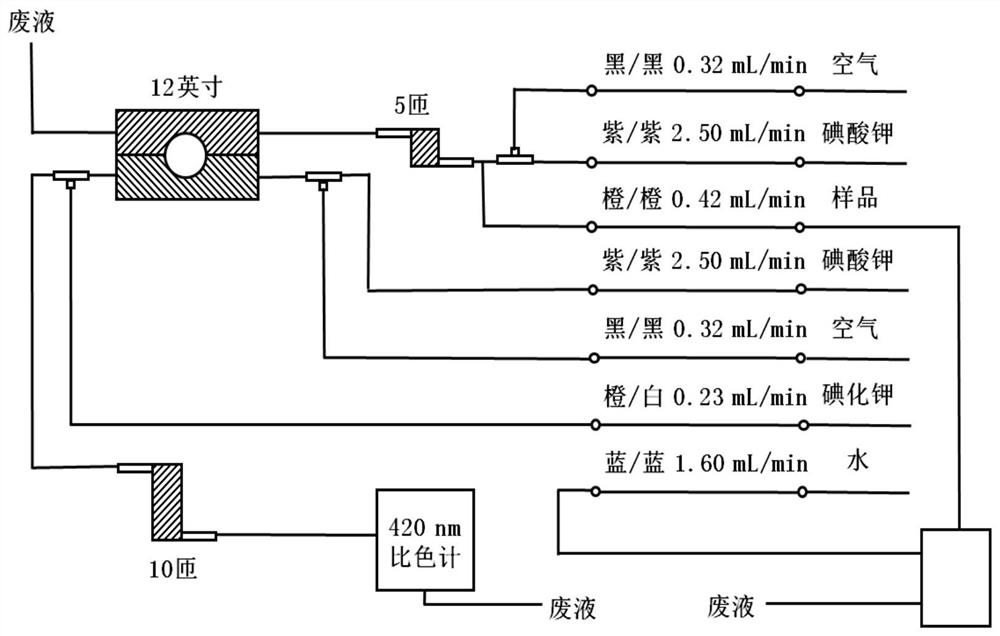

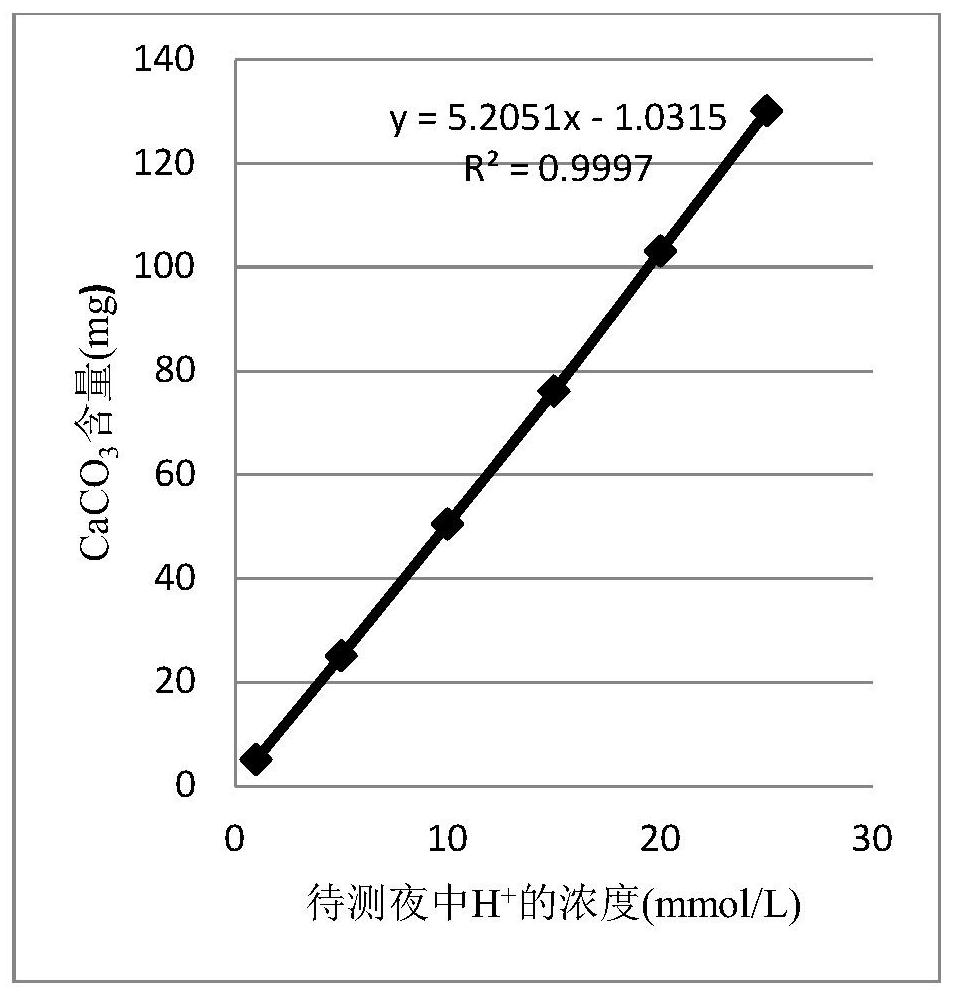

[0040] The cigarette paper sample is reacted with a known and accurate amount of excess HCl solution and filtered, and the continuous flow method is used to pass potassium iodate, potassium iodide and the remaining H in the sample solution. + color reaction to detect the remaining H + , so as to deduce the content of calcium carbonate in the cigarette paper sample.

[0041] 1.2 Materials and Instruments

[0042] Potassium iodate (AR, Shanghai Runjie Chemical Reagent Co., Ltd.); Potassium iodide (AR, Shanghai Chemical Reagent Co., Ltd.); Hydrochloric acid (AR, Shantou Xilong Chemical Plant, Guangdong); Calcium carbonate (working reference reagent (capacity), Tongji Institute of Trace Elements); activated carbon particles (China Pharmaceutical (Group) Shanghai Chemical Reagent Company).

[0043] MET...

Embodiment 2

[0066] Example 2——Detection of calcium carbonate content in cigarette paper webbing slurry.

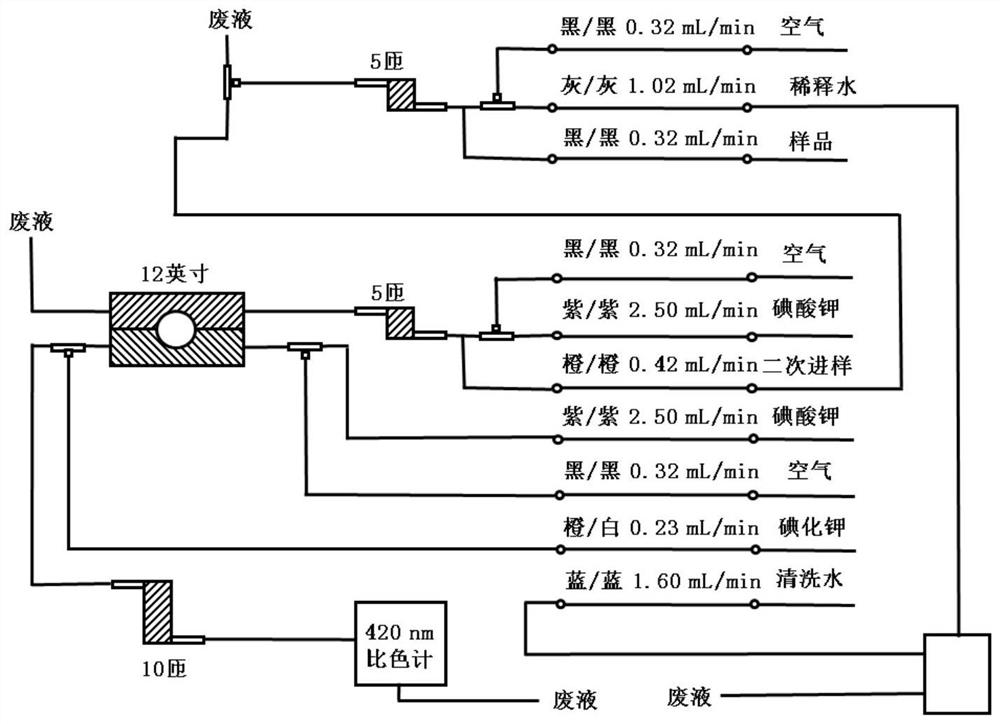

[0067] Repeat embodiment 1, have following difference: press Figure 4 The sampling point shown is W B Take 1000mL of non-white cigarette paper web surfing slurry, pour it into a clean tray, keep the liquid level, place it in an oven at 100°C and bake it to constant weight to obtain sample B. Weigh 0.5g (accurate to 0.01g) thin strips of sample B (about 0.5cm×2.5cm) baked at 105°C for 2h, put them into a 150mL beaker, add 4.5mL of 0.5mol / L hydrochloric acid solution, and use a glass rod to fully Stir until the fibers are dispersed and no air bubbles overflow, add 95.5mL of pure water, mix well and filter with qualitative filter paper, add 5g of activated carbon particles with a particle size of 400 mesh to the filtrate, shake for 25min to decolorize, filter with qualitative filter paper, and collect the filtrate as a sample Solution B is ready for use.

Embodiment 3

[0068] Example 3——Detection of calcium carbonate content in wood pulp fiber of cigarette paper.

[0069] Repeat embodiment 1, have following difference: press Figure 4 The sampling point shown is W 01 (or W 02 ) to take 1000mL of non-white cigarette paper wood pulp fiber, pour it into a clean tray, keep the liquid level flat, place it in an oven at 100°C and bake it to constant weight to obtain sample C. Weigh 0.5g (accurate to 0.01g) thin strips of sample C (about 0.5cm×2.5cm) baked at 105°C for 2 hours, put them into a 150mL beaker, add 4.5mL of 0.5mol / L hydrochloric acid solution, and use a glass rod to fully Stir until the fibers are dispersed and no air bubbles overflow, add 95.5mL of pure water, mix well and filter with qualitative filter paper, add 5g of activated carbon particles with a particle size of 400 mesh to the filtrate, shake for 25min to decolorize, filter with qualitative filter paper, and collect the filtrate as a sample C solution is ready for use.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com