Continuous flow electric field enhanced medium coalescence demulsification effect evaluation system and method

An electric field and medium technology, applied in the field of electric field enhanced medium coalescence demulsification effect evaluation system, can solve the problems of poor universality, poor recovery of dirty oil, high chemical consumption, etc., and achieve the effect of accurate results, optimized design, and rapid evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

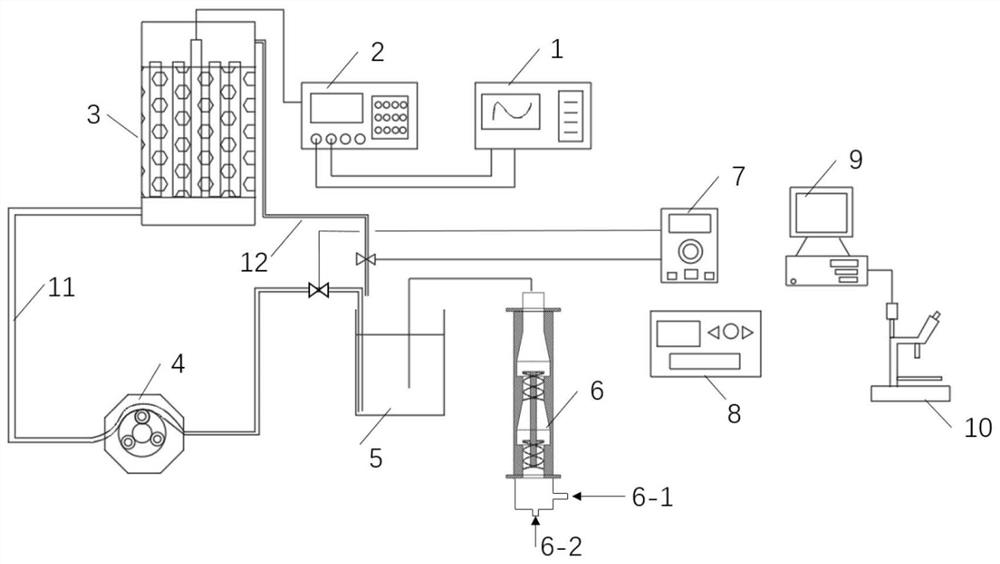

[0035] Such as figure 1 As shown, an electric field enhanced medium coalescence demulsification effect evaluation system, the evaluation system includes an emulsification system, a continuous flow system, an electric field enhanced medium coalescence demulsification system, and an online detection and analysis system; wherein:

[0036] The emulsification system includes a variable-diameter micro-mixer 6 for preparing an O / W emulsion, and the variable-diameter micro-mixer 6 includes an oil phase inlet 6-1 and a water phase inlet 6-2; the emulsification system also includes An emulsion storage tank 5 for storing the prepared O / W emulsion;

[0037] The continuous flow system includes a connection pipeline 11, one end of the connection pipeline 11 is inserted into the bottom end of the emulsion storage tank 5, and the other end is connected to the electric field enhanced medium coalescence demulsification system, and the connection pipeline 11 A peristaltic pump 4 for providing p...

Embodiment 2

[0053] The system and method for evaluating the coalescence and demulsification effect of the continuous flow electric field-enhanced medium described in Example 1 were used to process the O / W emulsion and analyze the coalescence and demulsification characteristics of the electric-field-enhanced medium.

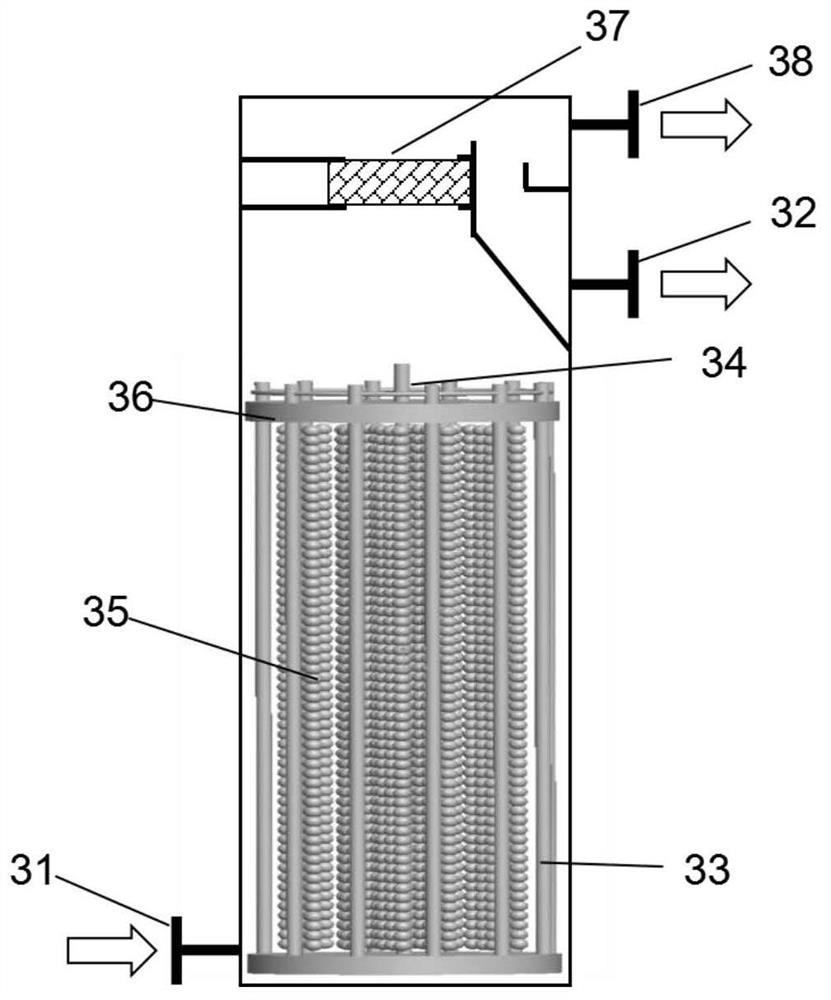

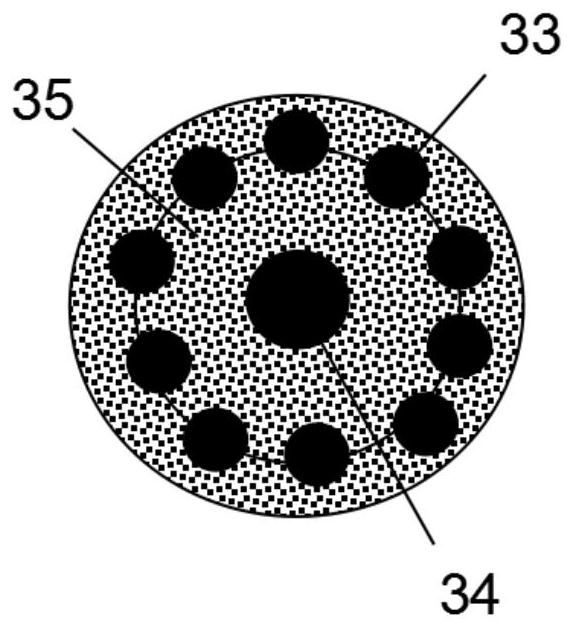

[0054] The internal diameter of the electric field enhanced medium coalescence demulsifier is 40mm; the diameter of the first rod-shaped electrode is 3mm, the length is 32cm, and the material is titanium metal, which is used as the cathode of the electrode assembly; the number of the second rod-shaped electrodes is 12 , the diameter of the outer ring rod electrode of the second rod electrode is 2mm, the length is 32mm, the material is metal titanium, communicated by a copper wire, as the anode of the electrode assembly; the fixed orifice plate is made of polytetrafluoroethylene; the power supply The electric field provided is a DC electric field with a voltage of 300V; the med...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com