Hot melt adhesive powder for polyethylene/polyurethane foam bonding, and preparation method and application thereof

A polyurethane foam and polyethylene technology, applied in the application, chemical instruments and methods, graft polymer adhesives and other directions, can solve the problems of poor adhesion of the polyurethane foam layer, etc., and achieve good thermal insulation effect, cost reduction, appearance smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

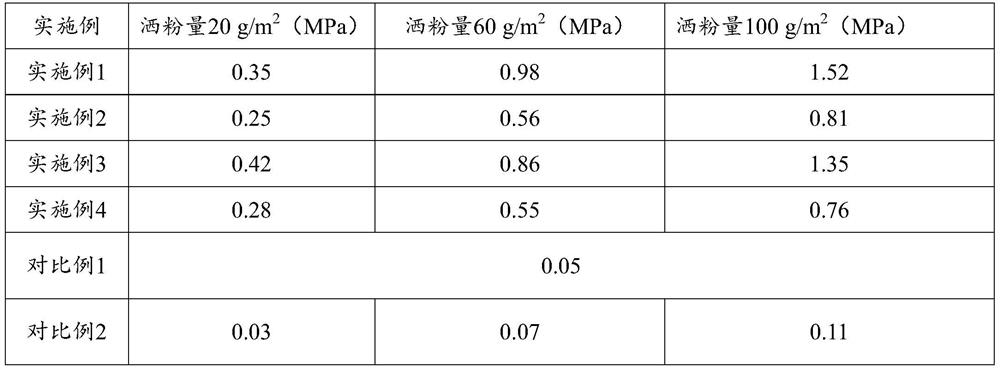

Examples

preparation example Construction

[0035] In one embodiment of the present invention, a kind of preparation method of the above-mentioned hot melt adhesive powder for polyethylene / polyurethane foam bonding is provided, and the specific steps are:

[0036] S1 Blending and granulation: After mixing the polar monomer-modified polyethylene, polyethylene, ethylene-vinyl acetate copolymer, and functional additives in proportion, the blend is extruded with a twin-screw extruder Granulate at 180°C-250°C, cut into pellets and dry for later use;

[0037] S2 milling: grind the blended and granulated materials in S1 with a plastic mill, and control the particle size of the powder to be 10 mesh to 200 mesh.

[0038] In one embodiment of the present invention, there is provided a kind of application of the above-mentioned hot melt adhesive powder for polyethylene / polyurethane foam bonding in spraying and winding insulation pipes;

[0039] In a specific embodiment, the method of application is: before the curing of the polyu...

Embodiment 1

[0042] Hot melt adhesive powder for polyethylene / polyurethane foam bonding, the composition of raw materials:

[0043] High-density polyethylene grafted with maleic anhydride (the graft rate of maleic anhydride is 0.8%) 99.5%;

[0044] Antioxidant B215 0.5%.

[0045] The specific steps for the preparation of hot melt adhesive powder for polyethylene / polyurethane foam bonding are:

[0046] S1 Blending and granulation: After mixing the high-density polyethylene grafted with maleic anhydride and antioxidant B215 evenly, use a twin-screw extruder to granulate the blend at 190°C-210°C, and dry it for later use ;

[0047] S2 milling: the blended and granulated material in S1 is milled with a plastic mill, and the particle size of the powder is controlled to be 30 mesh.

[0048] Application of hot melt adhesive powder for polyethylene / polyurethane foam bonding on spray-coated winding insulation pipes:

[0049] Choose dn508 steel pipe, after the surface is shot blasted and deruste...

Embodiment 2

[0051] Hot melt adhesive powder for polyethylene / polyurethane foam bonding, the composition of raw materials:

[0052] Acrylic acid grafted high-density polyethylene (grafting rate of acrylic acid is 2.5%) 30%;

[0053] PE 80 pipe material (DGDB 2480) 65%;

[0054] Carbon black masterbatch (carbon black content 45%) 4.5%;

[0055] Antioxidant 1010 0.5%.

[0056] The specific steps for the preparation of hot melt adhesive powder for polyethylene / polyurethane foam bonding are:

[0057] S1 Blending and granulation: Acrylic grafted high-density polyethylene, PE 80 pipe material, carbon black masterbatch, antioxidant 1010 are mixed evenly, and the blend is heated at 210°C-220°C with a twin-screw extruder Carry out granulation, cut into granules and dry for later use;

[0058] S2 milling: grind the blended and granulated materials in S1 with a plastic mill, and control the particle size of the powder to 50 mesh.

[0059] Application of hot melt adhesive powder for polyethylene / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com