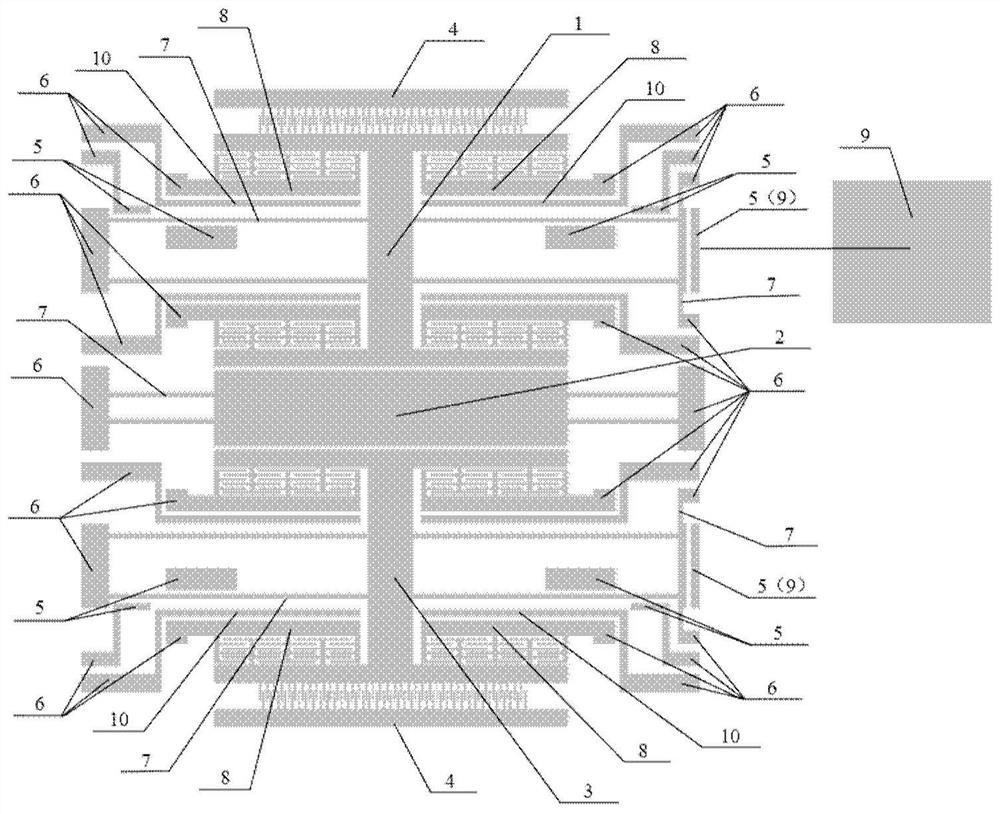

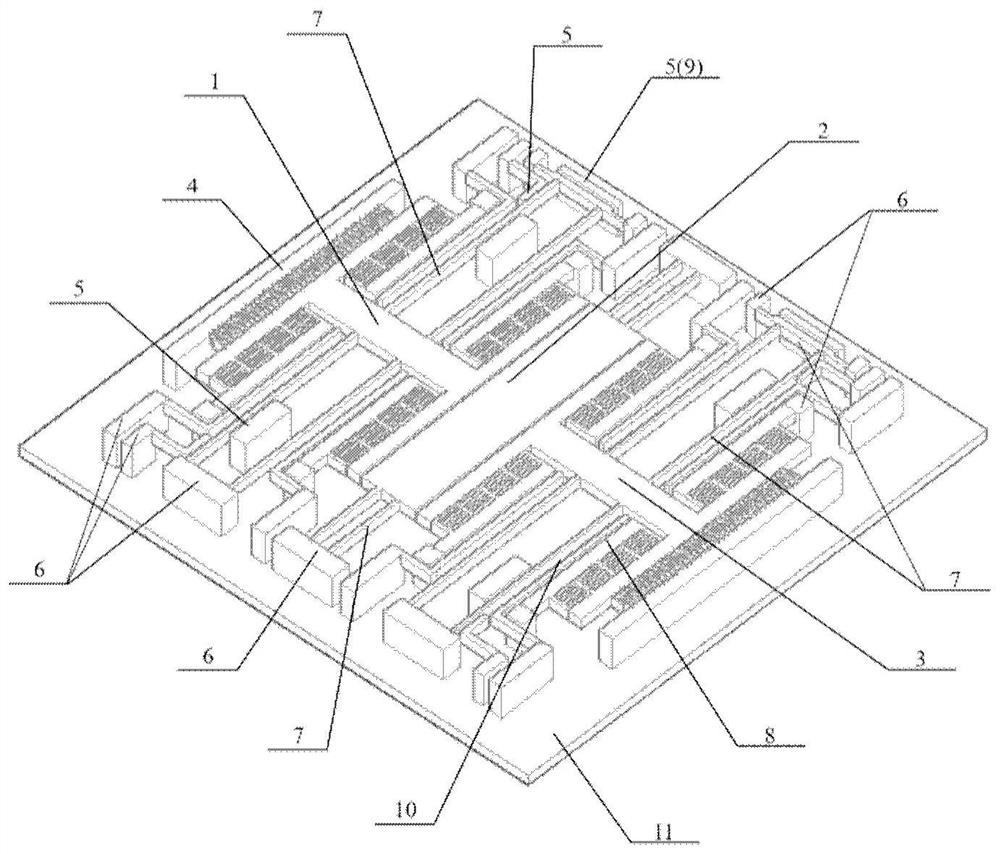

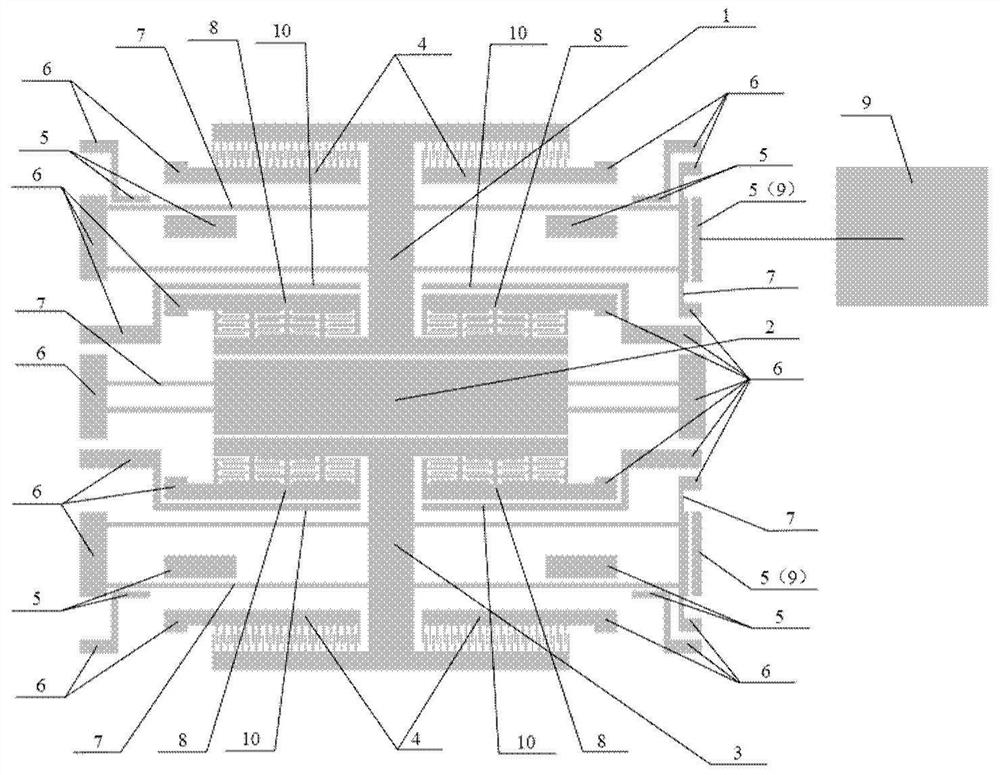

Miniature electric field sensor based on multi-structure coupling and preparation method of miniature electric field sensor

An electric field sensor, multi-structure technology, applied in electrostatic field measurement and other directions, can solve the problems of weak signal, low resolution, small size, etc., to achieve high stability, high sensitivity, and improve sensitivity and resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] A kind of preparation method of miniature electric field sensor as above-mentioned, wherein, comprise the following steps:

[0053] Coating photoresist on the front side of the SOI wafer, patterning the photoresist through a mask;

[0054] Etching the top layer of silicon to define the structural shapes of the first resonator, the second resonator, the third resonator, the electrode unit and the fixed anchor point;

[0055] Remove the photoresist and cut;

[0056] Use HF solution or HF gas to remove the oxide layer below the first resonator, the second resonator, the third resonator, and the electrode unit, release the structure, and retain the oxide layer below the fixed anchor point to fix it on the substrate silicon;

[0057] Preferably, the oxide layer needs to be preserved during the cutting step, so that the fragile resonator structure will not be damaged during the cutting process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com