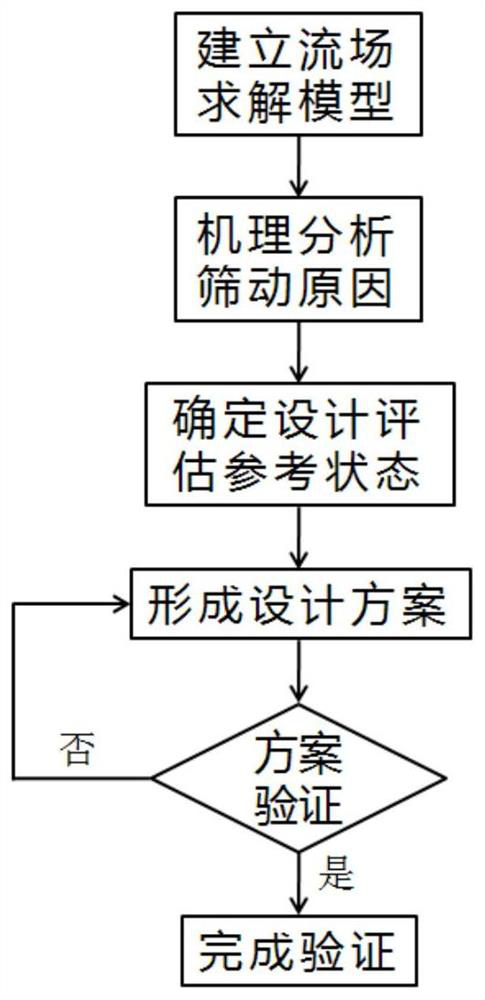

Design method of helicopter exhaust pipe shaping spoiler

A design method and exhaust pipe technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the problems of tail sieving, tail flow influence of exhaust pipe, and increasing vertical tail aerodynamics, etc. , to achieve the effects of suppressing tail sieving, simple design, and stable wake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

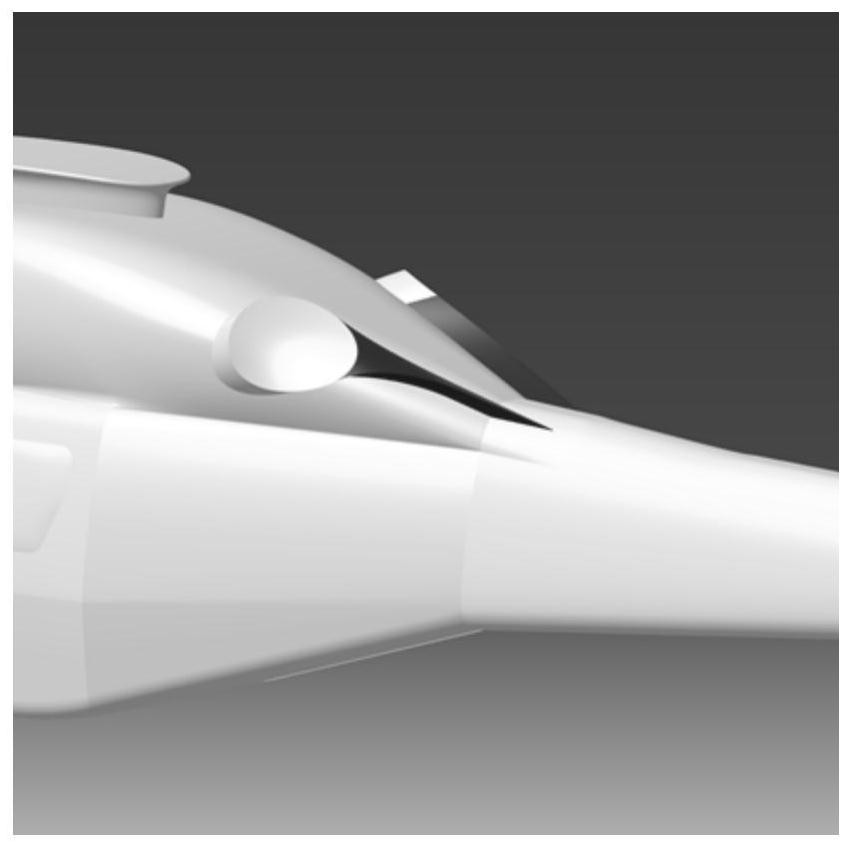

[0052] Using option 1, such as figure 2 As shown, it is a schematic diagram of the position of the exhaust pipe shaping spoiler compared to the fuselage in Scheme 1 of the present invention; the circular arc shape of the leeward surface of the exhaust pipe transitions to the shape of a sheet and connects with the tail beam skin;

[0053] like image 3 As shown, it is a schematic diagram of the shape and key parameters of the exhaust pipe shaping spoiler in Example 1 corresponding to Scheme 1; in Scheme 1, the shaping spoiler is in the shape of a "stretched Y" as a whole, and the specific design process is as follows:

[0054] First, determine the tangential position of the upper and lower surfaces of the spoiler to the annulus of the exhaust pipe and the joint position with the tail beam section, and then determine the contour line, which is consistent with the height of the exhaust pipe protruding from the surface of the body. Shrink towards the middle, and finally transiti...

Embodiment 2

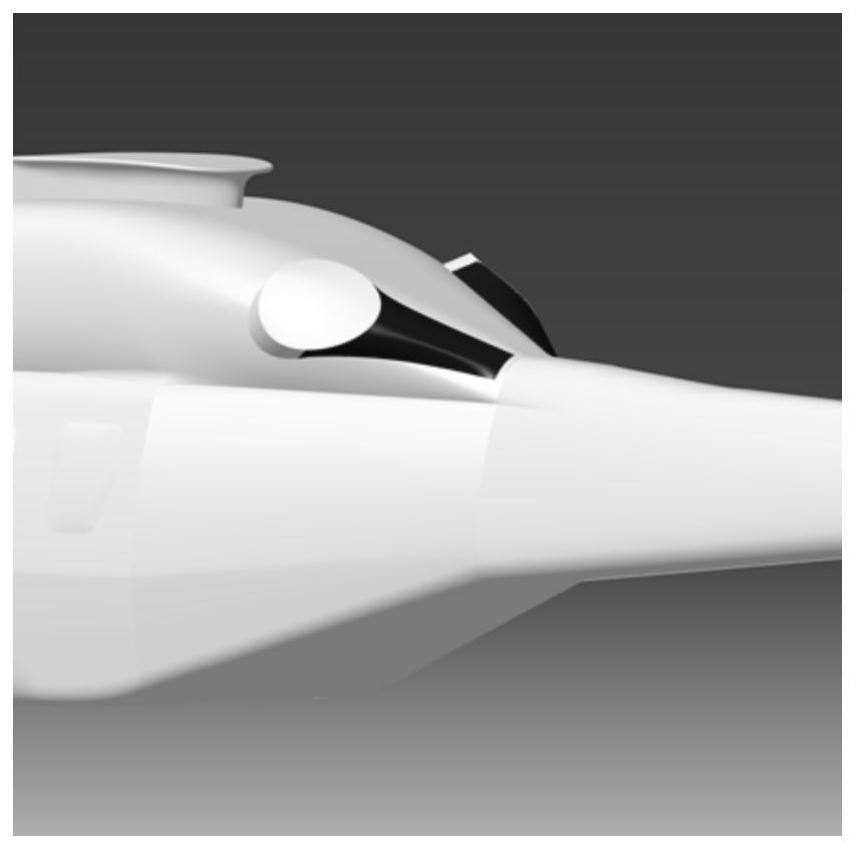

[0057] Using option 2, such as Figure 4 , Figure 5 as shown, Figure 4 It is a schematic diagram of the position of the exhaust pipe shaping spoiler compared to the fuselage in Scheme 2 of the present invention;

[0058] Figure 5 It is a schematic diagram of the shape and key parameters of the exhaust pipe shaping spoiler in Example 2 corresponding to Scheme 2;

[0059] Scheme 2 has a "compressed Y" shape as a whole, and a fairing is added on the leeward side of the exhaust pipe to connect with the fuselage skin; the specific design process is as follows:

[0060] First determine the position tangent to the exhaust pipe annulus and the fuselage surface. In order to obtain a smooth surface with consistent curvature, additional auxiliary lines need to be added. The initial height is consistent with the height of the exhaust pipe, and the height and span of the longitudinal spoiler of the fuselage gradually decrease. , and finally tangent to the fuselage surface, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com