Information recording medium and method for manufacturing same

A technology of information recording and manufacturing method, which is applied in the direction of optical record carrier manufacturing, data recording, information storage, etc., can solve the problems of deterioration of regeneration durability, difficulty of DC sputtering or pulsed DC sputtering, etc., and achieve excellent regeneration durability, The effect of high productivity and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

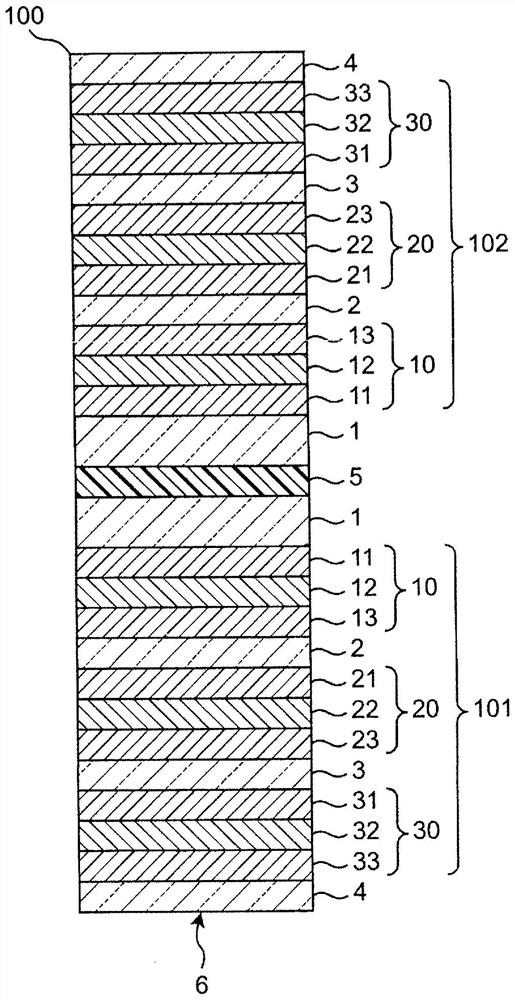

[0052] An information recording medium according to an embodiment of the present invention is an information recording medium that includes two or more information layers and records or reproduces information by irradiation with laser light, wherein,

[0053] Using at least one information layer among the two or more information layers as a first information layer, the first information layer contains in order from the far side to the near side of the surface irradiated with the laser light. a dielectric thin film and recording film,

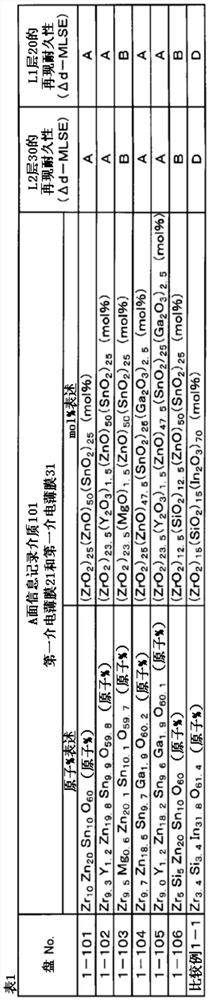

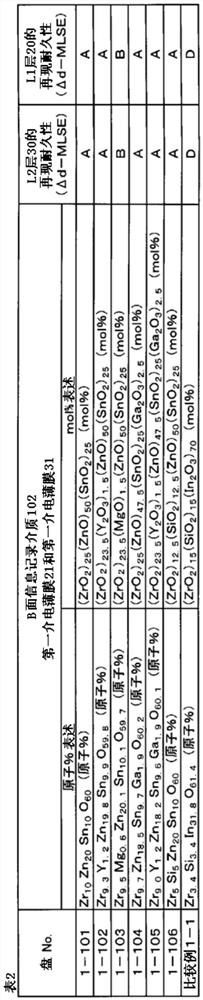

[0054] The first dielectric film contains at least Zr and oxygen, and also contains at least one element D1 selected from Zn and Sn. When the total number of atoms of Zr, oxygen, and the element D1 is 100 atomic %, Zr 3 atomic % or more and 26 atomic % or less, containing the element D1 is 10 atomic % or more and 43 atomic % or less,

[0055] The recording film contains at least W, Cu, Mn and oxygen, and further contains at least one element M ...

Embodiment approach 2

[0493] Next, as Embodiment 2, the manufacturing method of the information recording medium 100 demonstrated in Embodiment 1 is demonstrated.

[0494] The method for manufacturing an information recording medium according to an embodiment of the present invention is a method for manufacturing an information recording medium including two or more information layers, wherein,

[0495] comprising the step of forming the above two or more information layers respectively,

[0496] Using at least one information layer among the above two or more information layers as the first information layer, the step of forming the first information layer includes at least a step of forming a first dielectric thin film and a step of forming a recording film,

[0497] In the above step of forming the first dielectric film, a first dielectric film containing at least Zr and oxygen and at least one element D1 selected from Zn and Sn is formed,

[0498] In the above step of forming the recording fil...

Embodiment 1

[0563] In this example, the description figure 1 An example of the information recording medium 100 shown. The following describes the method of manufacturing the information recording medium 100 of this embodiment.

[0564] First, the configuration of the side A information recording medium 101 will be described. As the substrate 1 , a polycarbonate substrate (diameter 120 mm, thickness 0.5 mm) formed with spiral guide grooves (depth 27 nm, track pitch (land-groove distance) 0.225 μm) was prepared. On this substrate 1, an L0 layer 10 is formed. The following film formation is performed sequentially by sputtering: As the first dielectric thin film 11, a material substantially composed of (ZrO 2 ) 25 (SiO 2 ) 25 (In 2 o 3 ) 50 (mol%) target, so that (ZrO 2 ) 25 (SiO 2 ) 25 (In 2 o 3 ) 50 (mol%) film 13nm, as the recording film 12, use substantially by W 25 Cu 21 Ta 21 Zn 5 mn 28 The target formed by -O makes W 25 Cu 21 Ta 21 Zn 5 mn 28 -O film 34nm, as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com