Stropharia rugosoannulata extracting solution and preparation method thereof

A technology of Stropharia stropharcoides and its extraction solution, which is applied in food extraction, functions of food ingredients, food science, etc., can solve problems such as limited extraction efficiency, and achieve the effect of rich taste and strong antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

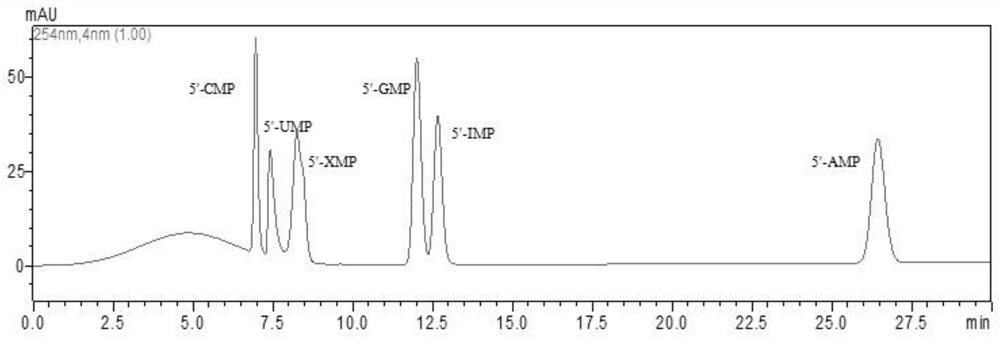

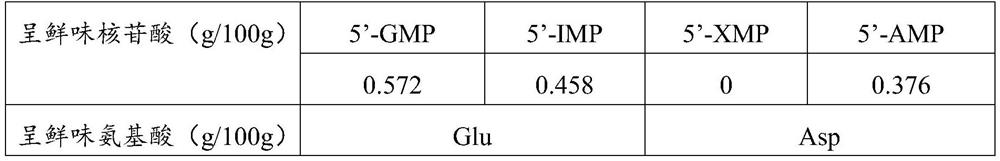

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of Stropharia grandis extract, comprising the following steps:

[0030] 1) mixing superfine powder of Stropharia stropharcota with water and a mixed enzyme solution, and performing enzymatic hydrolysis to obtain an enzymatic hydrolysis solution; the mixed enzyme solution includes cellulase, pectinase, 5'-phosphodiesterase and papain;

[0031] 2) treating the enzymolyzed solution under the condition of 200-600 MPa to deactivate the enzyme by ultra-high pressure to obtain the Stropharia stropharia mixed solution;

[0032] 3) The Stropharia stropharcota mixture is sequentially subjected to reduced-pressure low-temperature extraction and solid-liquid separation to obtain an extract;

[0033] 4) separating the supernatant from the extract to obtain the extract of Stropharia grandis.

[0034] In the invention, the superfine powder of Stropharia stropharia is mixed with water and a mixed enzyme liquid, and enzymatically hydr...

Embodiment 1

[0052] (1) Slice the fresh Stropharia stropharia to 6 mm, dry it, crush it to 80 mesh, and then pulverize it to obtain superfine powders of Stropharia stropharia with different particle sizes, and select Stropharia stropharia powder with a particle size of 180 μm for extraction Preparation of liquid: add pure water to the mushroom powder for extraction, the ratio of solid to liquid is 1g:30mL; the volume of the compound enzyme liquid added accounts for 8% of the total volume of the mushroom liquid, cellulase, pectinase, 5'-phosphodiester The mass ratio of enzyme and papain is 10:1:5:5. Under the condition of 600MP, the enzyme was killed by ultra-high pressure, and the solubilization treatment was carried out for 30 minutes.

[0053] (2) The extract solution after ultra-high pressure treatment is subjected to vacuum cold extraction. When the external pressure decreases, the boiling point of the extract solution decreases, and the volatile and non-volatile components can be furt...

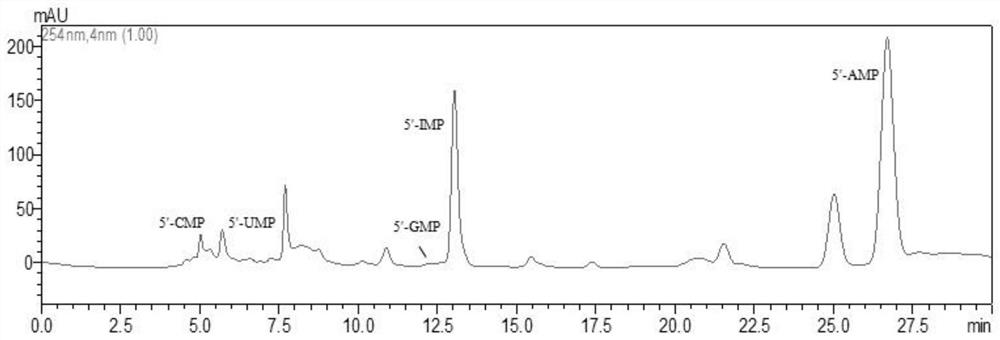

Embodiment 2

[0070] (1) Slice the fresh Stropharia stropharia to 6mm, dry it, crush it to 80 meshes, and then pulverize it to obtain superfine powders of Stropharia stropharia with different particle sizes, and select Stropharia stropharia powder with a particle size of 90 μm for extraction Preparation of liquid: add pure water to the mushroom powder for extraction, the ratio of solid to liquid is 1g:20mL; The mass ratio of papain is 15:5:5:1. Under the condition of 500MP, the enzyme was killed by ultra-high pressure, and the solubilization treatment was performed for 25 minutes.

[0071] (2) The extract solution after ultra-high pressure treatment is subjected to vacuum cold extraction. When the external pressure decreases, the boiling point of the extract solution decreases, and the volatile and non-volatile components can be further dissolved. The operation is carried out in a decompression drying oven: the vacuum degree is set to 0pa, the temperature of the decompression oven is adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com