Preparation method and application of iron/lanthanum manganate catalyst

A catalyst, lanthanum manganate technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of inability to meet emission requirements, low TOC removal rate, etc., and achieve easy regeneration and low cost. , high active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

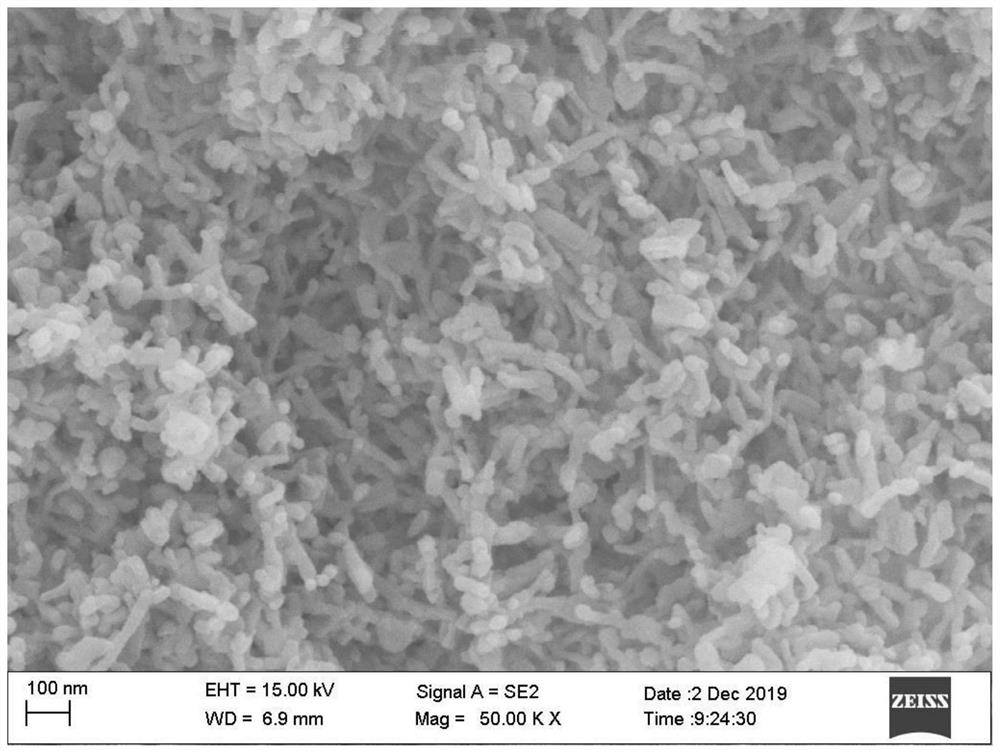

[0034] Weigh 9.0101g La(NO 3 ) 3 ·6H 2 O, 8.4491g Fe(NO 3 ) 3 9H 2 Dissolve O in 100mL distilled water and mix well; take 8mL ammonia water and 0.25g polyethylene glycol (PEG) (molecular weight: 20000) and add them into 92mL distilled water; add the well-mixed lye into the salt solution drop by drop, and stir magnetically after the dropwise addition One hour; as for aging at 100°C for 24 hours, vacuum filter, wash with distilled water to a medium size, filter and dry in an oven at 120°C for 14 hours, then use a muffle furnace to heat up to 3°C / min in an air atmosphere. Calcined at 800°C for 4h, recorded as LaFeO 3 . to LaFeO 3Physical adsorption characterization (see Table 1) and SEM characterization (see image 3 ), and carried out catalytic ozonation experiment, reaction conditions: normal temperature, normal pressure, 100ppm m-cresol model wastewater, initial pH of wastewater: 7.0, O 3 (mg / L):COD(mg / L)=1.9:1, the ratio of ozone flow to wastewater flow is 3.7:1.

Embodiment 2

[0036] Weigh 9.0538g La(NO 3 ) 3 ·6H 2 O, 7.4085g Mn(NO 3 ) 2 (50%) dissolved in 100mL of distilled water and mixed evenly; take 8mL of ammonia water and 0.25g of polyethylene glycol (PEG) (molecular weight 20000) and add it to 92mL of distilled water; add the well-mixed lye to the salt solution drop by drop, and the dropwise addition is completed Then magnetically stir for one hour; as for aging at 100°C for 24 hours, vacuum filter, wash with distilled water to medium size, dry in an oven at 120°C for 14 hours after filtration, and then use a muffle furnace to heat up at 3°C / min in an air atmosphere The temperature was raised to 800 ° C for 4 hours, and it was recorded as LaMnO 3 . to LaMnO 3 Physical adsorption characterization (see Table 1) and SEM characterization (see Figure 4 ), and carried out catalytic ozonation experiment, reaction conditions: normal temperature, normal pressure, 100ppm m-cresol model wastewater, initial pH of wastewater: 7.0, O 3 (mg / L):COD(...

Embodiment 3

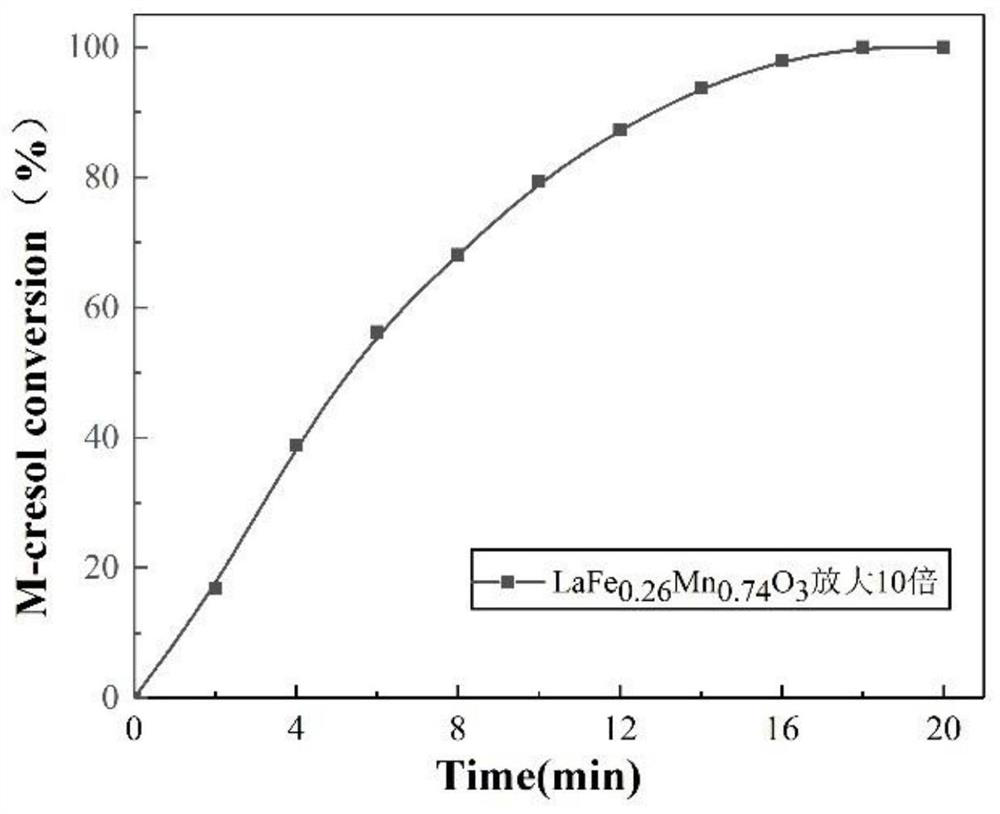

[0038] Weigh 9.0101g La(NO 3 ) 3 ·6H 2 O, 4.2246g Fe(NO 3 ) 3 9H 2 O, 3.6864g Mn(NO 3 ) 2 (50%) dissolved in 100mL of distilled water and mixed evenly; take 8mL of ammonia water and 0.25g of polyethylene glycol (PEG) (molecular weight 20000) and add it to 92mL of distilled water; add the well-mixed lye to the salt solution drop by drop, and the dropwise addition is completed Then magnetically stir for one hour; as for aging at 100°C for 24 hours, vacuum filter, wash with distilled water to medium size, dry in an oven at 120°C for 14 hours after filtration, and then use a muffle furnace to heat up at 3°C / min in an air atmosphere The temperature is raised to 800°C for 4 hours, and it is recorded as LaFe 0.5 mn 0.5 o 3 . to LaFe 0.5 mn 0.5 o 3 Physical adsorption characterization (see Table 1) and SEM characterization (see Figure 5 ), and carried out catalytic ozonation experiment, reaction conditions: normal temperature, normal pressure, 100ppm m-cresol model wast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com