Low-temperature quick-curing polyester resin and powder coating for coiled materials prepared from same

A polyester resin, fast curing technology, used in powder coatings, polyester coatings, polyamide coatings, etc., can solve problems such as the inability to achieve low temperature curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

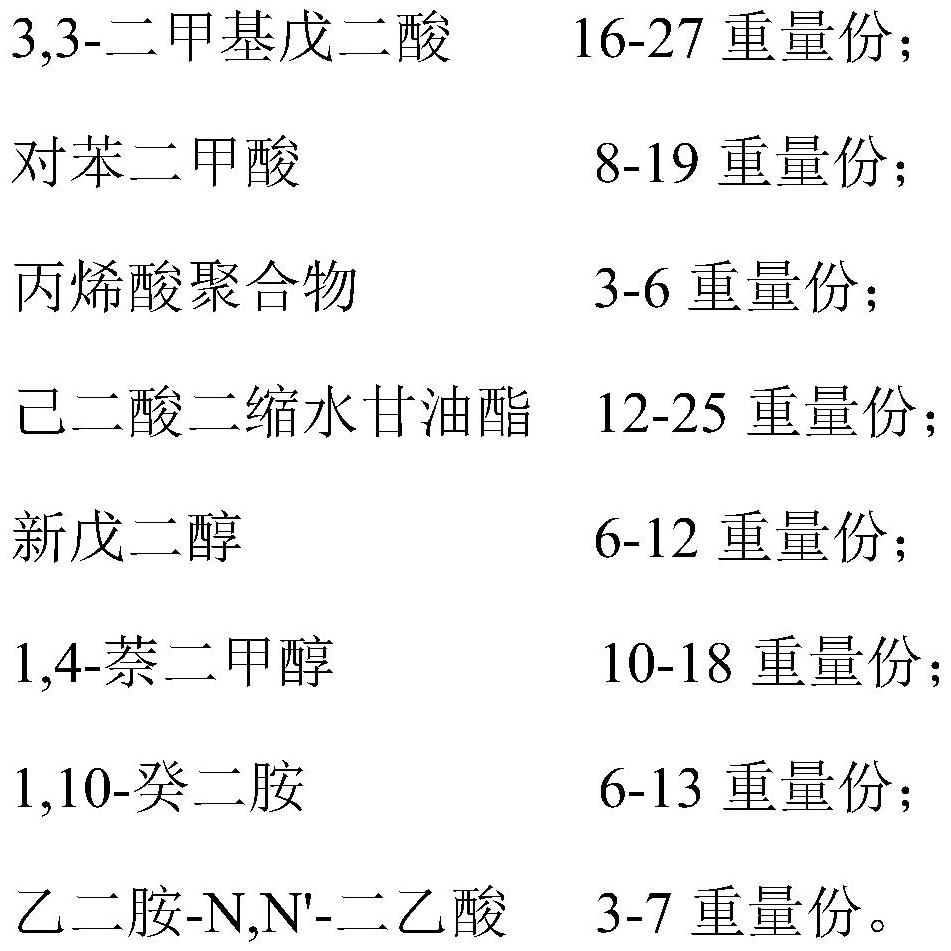

[0029] The low-temperature fast-curing type polyester resin described in this embodiment, its preparation raw material comprises the following components by weight:

[0030]

[0031] Monobutyl tin oxide, its consumption is 0.05wt% of preparation raw material total amount;

[0032] Antioxidant 1010, its dosage is 0.5wt% of the total amount of raw materials for preparation.

[0033] The preparation method of the low-temperature fast-curing type polyester resin described in the present embodiment comprises the following steps:

[0034] (1) Add the neopentyl glycol, 1,4-naphthalene dimethanol, and diglycidyl adipate into the reactor, and heat and melt below 135°C;

[0035] (2) Add formulated amount of 3,3-dimethylglutaric acid and terephthalic acid to the above mixed material, and add formulated amount of catalyst at the same time, under the protection of nitrogen, gradually raise the temperature to 195°C at 10°C / h ℃, insulation reaction;

[0036] (3) When the acid value is ...

Embodiment 2

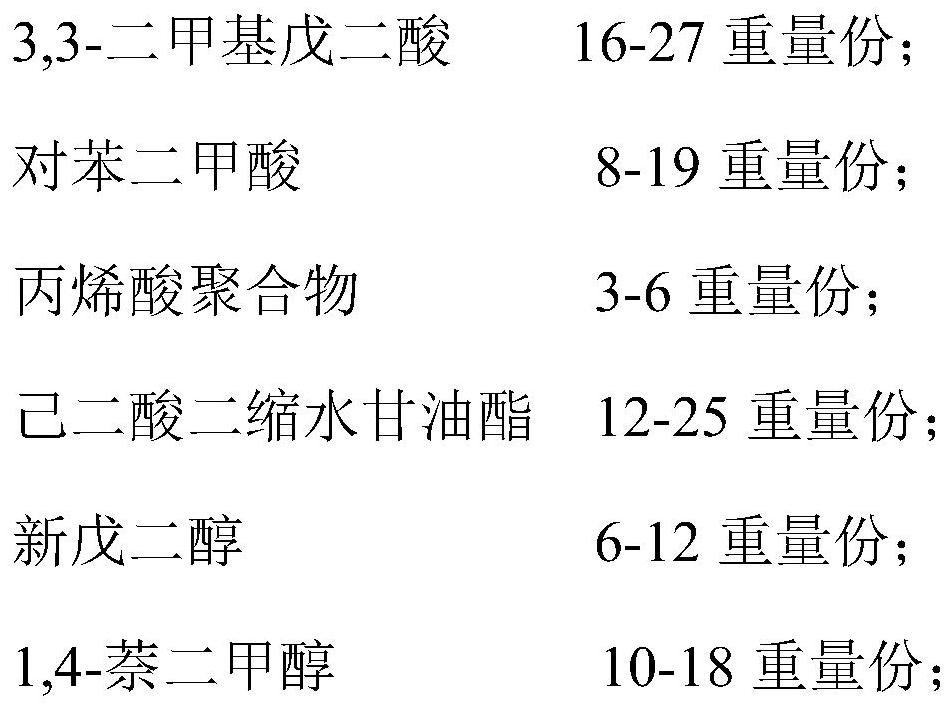

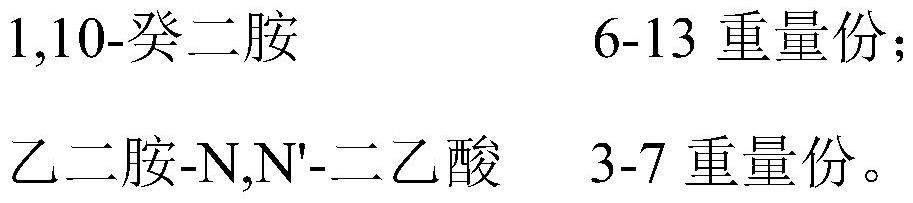

[0041] The low-temperature fast-curing type polyester resin described in this embodiment, its preparation raw material comprises the following components by weight:

[0042]

[0043] Monobutyltin oxide, its consumption is 0.2wt% of preparation raw material total amount;

[0044]Antioxidant 1010, its dosage is 0.3wt% of the total amount of raw materials for preparation.

[0045] The preparation method of the low-temperature fast-curing type polyester resin described in the present embodiment comprises the following steps:

[0046] (1) Add the neopentyl glycol, 1,4-naphthalene dimethanol, and diglycidyl adipate into the reactor, and heat and melt below 135°C;

[0047] (2) Add formulated amount of 3,3-dimethylglutaric acid and terephthalic acid to the above mixed material, and add formulated amount of catalyst at the same time, under the protection of nitrogen, gradually raise the temperature to 190°C at 12°C / h ℃, heat preservation reaction;

[0048] (3) When the acid value...

Embodiment 3

[0053] The low-temperature fast-curing type polyester resin described in this embodiment, its preparation raw material comprises the following components by weight:

[0054]

[0055]

[0056] Monobutyltin oxide, its consumption is 0.1wt% of preparation raw material total amount;

[0057] Antioxidant 1010, its dosage is 0.3wt% of the total amount of raw materials for preparation.

[0058] The preparation method of the low-temperature fast-curing type polyester resin described in the present embodiment comprises the following steps:

[0059] (1) Add the neopentyl glycol, 1,4-naphthalene dimethanol, and diglycidyl adipate into the reactor, and heat and melt below 135°C;

[0060] (2) Add formulated amount of 3,3-dimethylglutaric acid and terephthalic acid to the above mixed material, and simultaneously add formulated amount of catalyst, and gradually raise the temperature to 200°C at 11°C / h under the protection of nitrogen. ℃, insulation reaction;

[0061] (3) When the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Total amine value | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com