A preparation method of a saturable absorber and a multimode fiber laser

A saturable absorption, multimode fiber technology, applied in the field of laser technology and nonlinear optics, can solve the problem of low output pulse energy, and achieve the effect of high saturation power and high modulation depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The invention provides a graphene-coated multi-mode micro-nano optical fiber saturable absorber, comprising: a multi-mode micro-nano optical fiber and a graphene deposition layer deposited thereon by an optical deposition method.

Embodiment 2

[0030] The preparation method of the graphene-coated multimode micro-nano optical fiber saturable absorber of the present invention comprises the following steps:

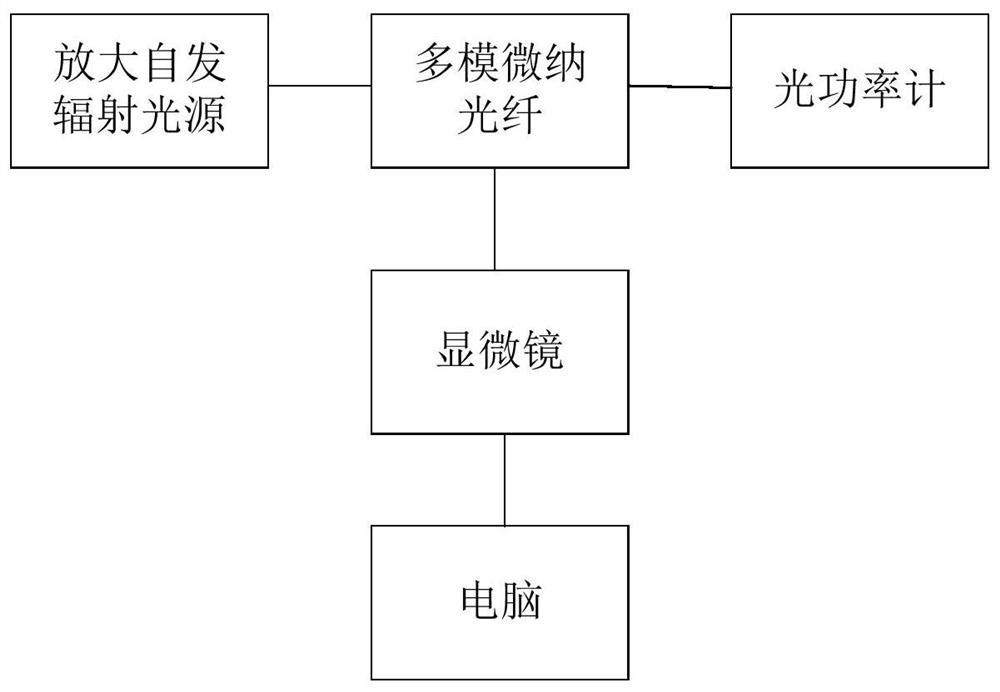

[0031] (1) Peel off the coating layer of an ordinary graded-index multimode fiber with a core diameter of 50 microns or 62.5 microns and wipe it clean with alcohol, then heat it on an alcohol lamp to taper it to Multimode micro-nano fiber with a diameter of 4-20 microns. Among them, the input end of the multimode micro-nano fiber is connected to the amplified spontaneous emission light source, the output end is connected to the optical power meter, and the amplified spontaneous emission light source is turned on during the tapering process to monitor the loss in the tapering process in real time through the power meter, so that the loss lower than 3dB;

[0032] (2) Keep the connection between the amplified spontaneous emission light source and the optical power meter and the multimode micro-nano fiber, and fix the...

Embodiment 3

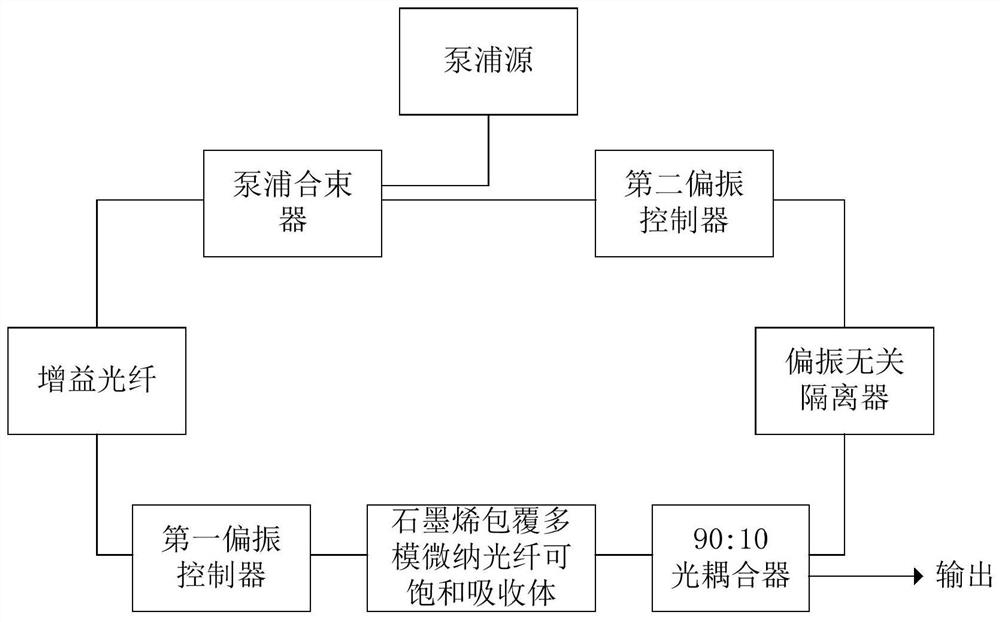

[0035] The all-fiber structure high-energy Q-switched mode-locked multimode fiber laser of the present invention is a ring cavity structure, such as image 3 As shown, by sequentially connecting pump beam combiner, gain fiber, first polarization controller, graphene-coated multimode micro-nano fiber saturable absorber, 90:10 optical coupler, polarization-independent isolator, second polarization The controller and the pump combiner form an annular chamber. The pump source is connected to the resonant cavity through the other end of the pump beam combiner, and the 10% port of the optical coupler is used as the output of the laser cavity to monitor the output characteristics of the laser cavity.

[0036] In this embodiment, the gain fiber is an ytterbium-doped few-mode fiber with a core diameter of 10 microns and a cladding diameter of 125 microns. The two pigtails connected to the pump beam combiner, the gain fiber and the second polarization controller are both few-mode fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com