Synthetic method and process of halogenated cyclopropane

A dihalocyclopropane and synthesis method technology, which is applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, dehalogenation preparation, etc., can solve the problems of high cost of raw materials, difficulties in waste recycling, and difficulty in industrial scale-up Production and other issues, to achieve the effects of easy reaction control, resource reuse, and less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

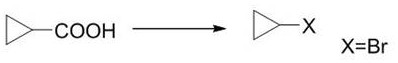

[0031] 1. Synthesis and process of bromocyclopropane

[0032] 1.11,1-Dibromocyclopropane

[0033] name molecular weight moles Feed amount The molar ratio of Cypromine 57.10 1 57.1 g 1 tert-butyl nitrite 103.12 1.1 113.5 g 1.1 copper bromide 223.35 2.0 446.74 2.0 Tetrahydrofuran 500mL

[0034] Add cyclopropylamine, tetrahydrofuran and copper bromide into the three-necked flask, stir evenly, and raise the temperature to 50°C. Add tert-butyl nitrite dropwise through the dropping funnel, and react at 50°C for 4 h after dropping. Use gas chromatography to track the progress of the reaction. After the reaction is completed, the temperature is lowered. After filtration, the filtrate was concentrated under reduced pressure to obtain 180 g of 1,1-dibromocyclopropane, gas chromatography purity: 95%, yield: 90%.

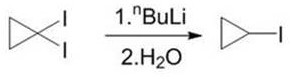

[0035] 1.2 Cyclopropane bromide

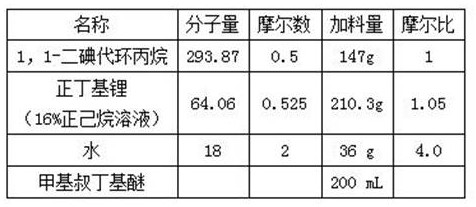

[0036]

[0037]

[0038] Add 1,1-dibromocyclopropane and methyl tert-bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com