Degradable high-performance plant fiber filled polypropylene composite material and preparation method thereof

A plant fiber and composite material technology, applied in the field of polypropylene composite materials and its preparation, can solve the problems of incomplete degradation, poor mechanical properties, poor fluidity, etc., achieve excellent reinforcement performance, improve fluidity, and reduce the amount of VOC Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

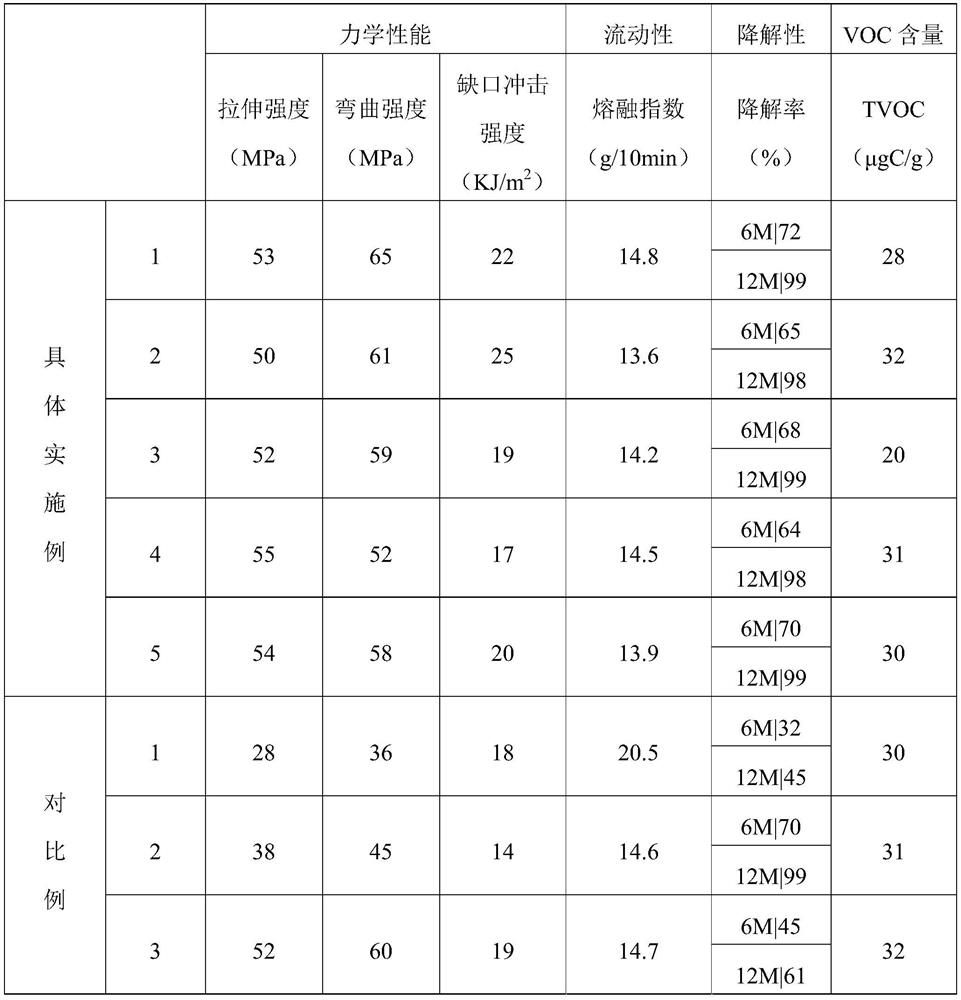

Examples

Embodiment Construction

[0025] In order to be able to understand the technical means of the present invention more clearly and implement it according to the contents of the description, the specific embodiments of the present invention will be further described in detail below in conjunction with specific examples. The following examples are used to illustrate the present invention, but not to limit it scope of the invention.

[0026] According to the dosage of each component described in Table 1, the polypropylene composite material described in the specific example was prepared by the following preparation method. The preparation method of the degradable high-performance plant fiber-filled polypropylene composite material mainly includes the following steps:

[0027] S1, take each component by the amount shown in Table 1;

[0028] S2, after soaking the plant fibers in a sodium hydroxide solution with a concentration of 18wt.% for 1-2 hours, wash the soaked plant fibers with water, and then place t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com