Preparation method for scandium oxide coated carbon nanotube reinforced magnesium-based composite material

A technology of composite materials and carbon nanotubes, applied in the field of metal matrix composite materials, to achieve low process cost, fine grain structure, and avoid damage and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

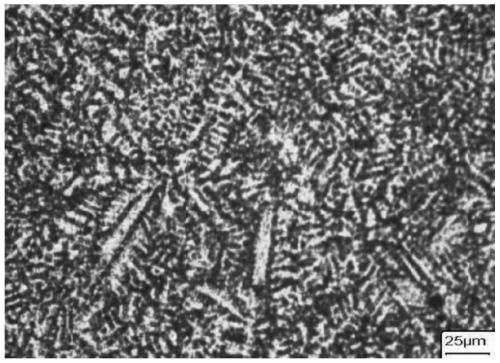

Embodiment 1

[0033] A scandium oxide-coated carbon nanotube reinforced magnesium-based composite material (AZ91-0.3wt%Sc 2 o 3 @CNTs) preparation method

[0034] (1) Preparation of reinforcement prefabricated blocks

[0035] Carbon nanotubes coated with scandium oxide (Sc 2 o 3 @CNTs) powder (purity above 90%) 0.3g, Al powder (purity 99%) 9g, Zn powder (purity 99%) 0.7g and stearic acid (melting point 75°C) 1g were mixed and added to the ball mill. Ball milling was carried out using a horizontal rotary ball mill. Use stainless steel grinding balls with diameters ranging from 4mm to 16mm, the ball-to-material ratio is 3:1, the ball milling speed is 200rpm, and the ball milling time is 180min. The liquid ball milling method is used, and 20ml of ethanol is added as a medium to protect the whole ball milling process from impurities. and oxidation interference, take out the mixture solution after the ball milling is completed, filter and dry to obtain the mixture powder.

[0036] Add the ...

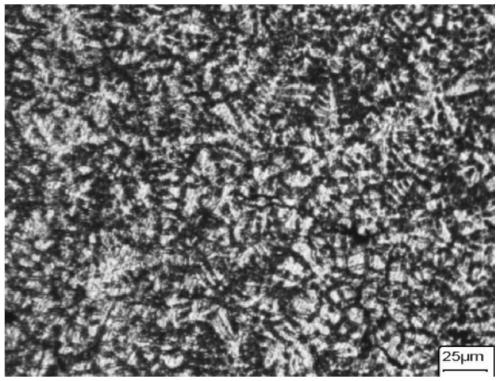

Embodiment 2

[0042] A scandium oxide-coated carbon nanotube reinforced magnesium-based composite material (AZ91-0.5wt%Sc 2 o 3 @CNTs) preparation method

[0043] (1) Preparation of reinforcement prefabricated blocks

[0044] The carbon nanotube powder 0.5g (Sc 2 o 3 @CNTs purity 90% or more), Al powder (purity 99%) 9.5g, Zn powder (purity 99%) 1g and stearic acid (melting point 75°C) 1.5g are mixed and added to the ball mill. Ball milling was carried out using a horizontal rotary ball mill. Use stainless steel balls ranging in size from 4mm to 16mm in diameter, the ball-to-material ratio is 3:1, the ball milling speed is 100rpm, and the ball milling time is 240min. The liquid ball milling method is used, and 20ml of ethanol is added as a medium to protect the whole ball milling process from impurities. and oxidation interference.

[0045] After the ball milling is completed, the mixture solution is taken out, filtered and dried to obtain the mixture powder. Add the mixture powder in...

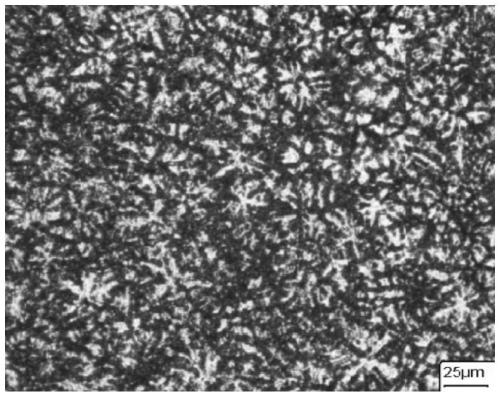

Embodiment 3

[0051] A scandium oxide-coated carbon nanotube reinforced magnesium-based composite material (AZ91-0.8wt%Sc 2 o 3 @CNTs) preparation method

[0052] (1) Preparation of reinforcement prefabricated blocks

[0053] The carbon nanotube powder 0.8g (Sc 2 o 3 @CNTs purity 90% or more), Al powder (purity 99%) 9.2g, Zn powder (purity 99%) 1g and stearic acid (melting point 75°C) 1g are mixed and added to the ball mill. Ball milling was carried out using a horizontal rotary ball mill. Use stainless steel balls ranging in size from 4mm to 16mm in diameter, the ball-to-material ratio is 3:1, the ball milling speed is 300rpm, and the ball milling time is 240min. The liquid ball milling method is used, and 20ml of ethanol is added as a medium to protect the whole ball milling process from impurities. and oxidation interference.

[0054] After the ball milling is completed, the mixture solution is taken out, filtered and dried to obtain the mixture powder. Add the mixture powder into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com