SERS substrate and preparation method and application thereof

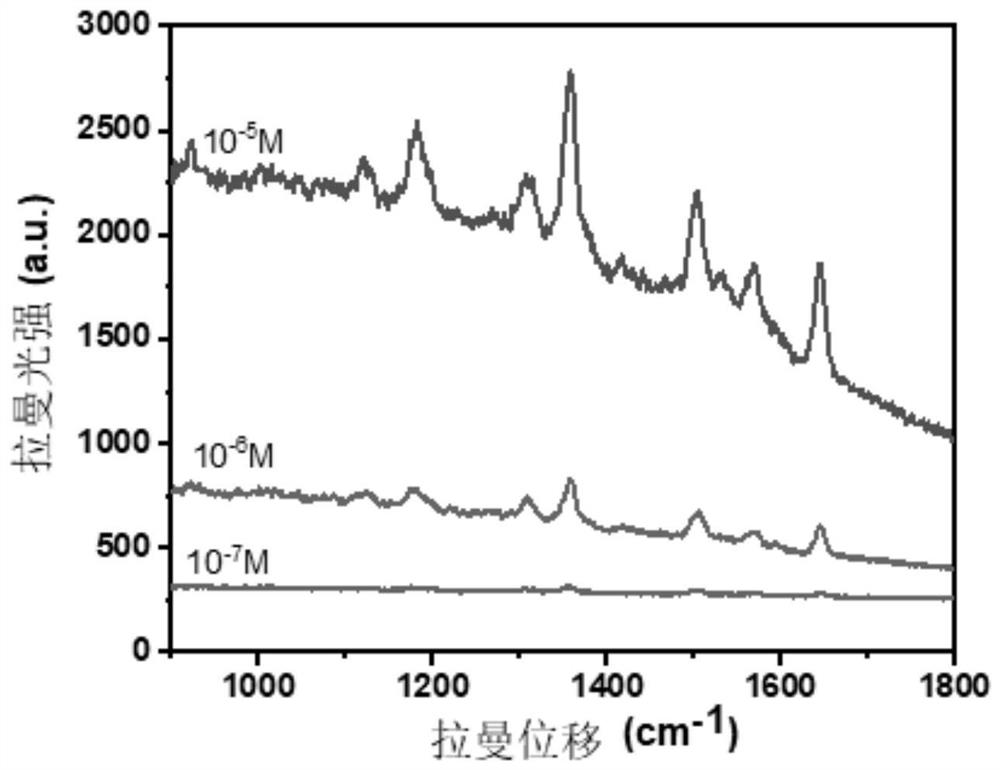

A substrate and substrate technology, applied in the field of laser applications, can solve problems such as difficult to control orderly directional growth of wrinkles, without considering stress distribution, etc., and achieve excellent enhancement performance and high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

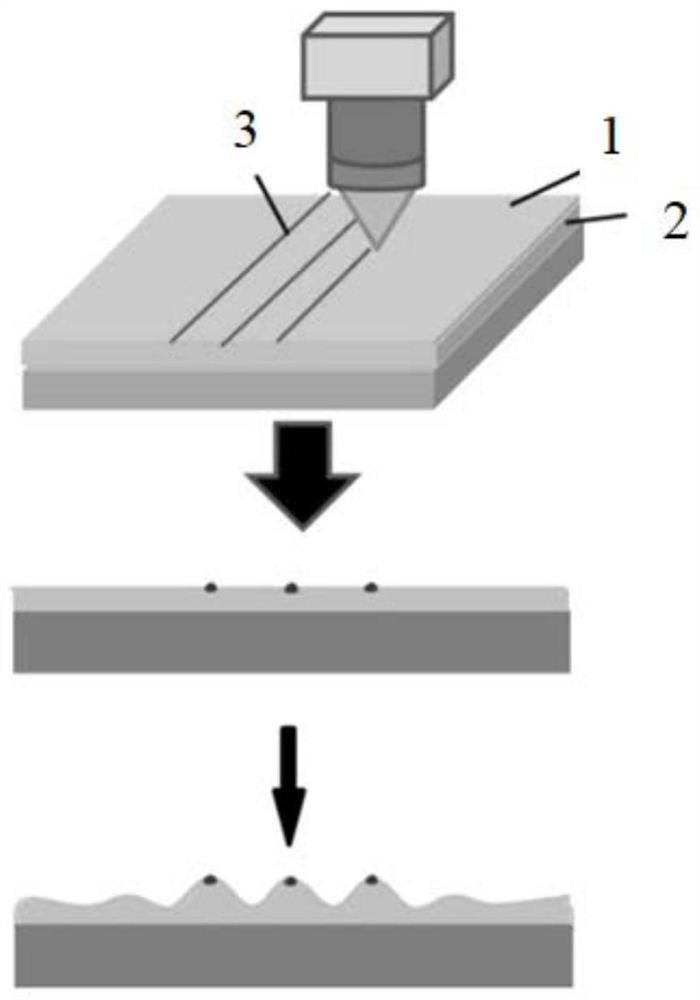

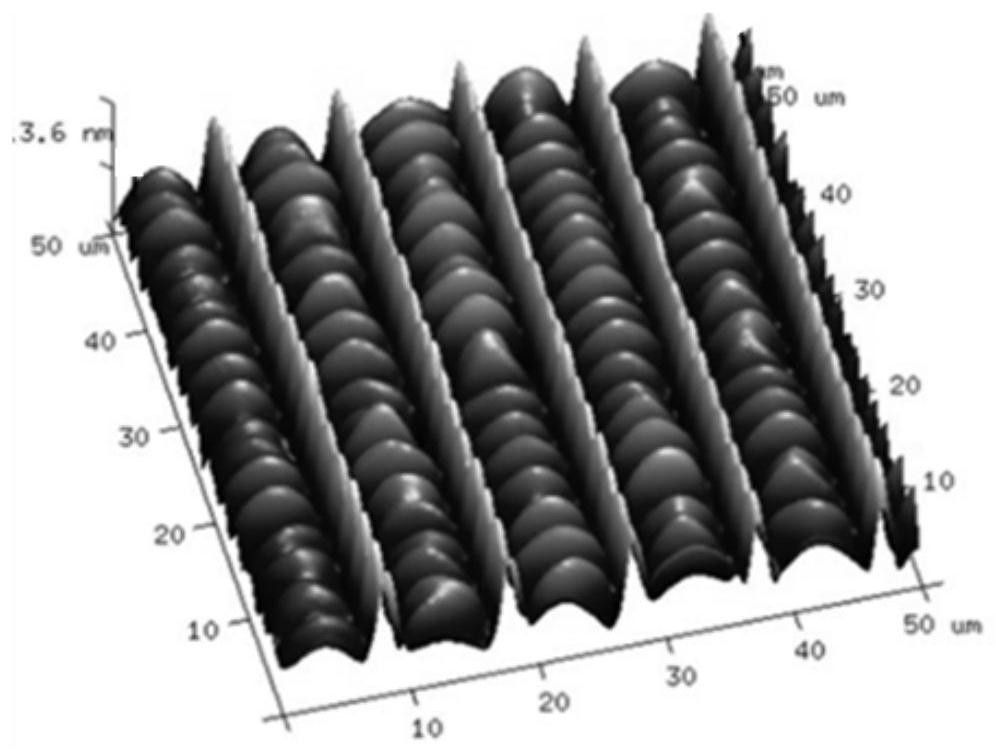

[0057] This embodiment provides a SERS substrate, which includes a second metal film (gold, with a thickness of 30 nm), a first metal film (gold, with a thickness of 5 nm), and a polymer film (PS, with a thickness of 36nm), its microstructure is as Figure 4 , Figure 5 shown by Figure 4-Figure 5 It can be seen that the wrinkles of the resulting SERS substrate are uniformly distributed in nanoscale size.

[0058] This embodiment also provides the preparation method of described SERS substrate, and described preparation method comprises the following steps:

[0059] (1) Ultrasonic cleaning of the glass sheet with acetone, absolute ethanol and deionized water in sequence, drying in an oven after drying with nitrogen, dissolving the polymer (PS) in the solvent, and ultrasonic vibration to obtain the polymer solution;

[0060] (2) Spin-coat the polymer solution on a glass sheet at a speed of 8000r / min, and heat it at 80°C to obtain a polymer film;

[0061] (3) Depositing the...

Embodiment 2

[0064] This embodiment provides a SERS substrate, which includes a second metal film (silver, with a thickness of 20 nm), a first metal film (silver, with a thickness of 3 nm), and a polymer film (PDMS, with a thickness of 20 nm) stacked in sequence. 30nm).

[0065] This embodiment also provides the preparation method of described SERS substrate, and described preparation method comprises the following steps:

[0066] (1) Ultrasonic cleaning of the glass sheet with acetone, absolute ethanol and deionized water in sequence, blowing dry with nitrogen and drying in an oven, dissolving the polymer (PDMS) in the solvent, and ultrasonically vibrating to obtain the polymer solution;

[0067] (2) Spin-coat the polymer solution on a glass sheet at a speed of 6000r / min, and heat it at 100°C to obtain a polymer film;

[0068] (3) Depositing the first metal (silver) film on the polymer film by ion sputtering to obtain the metal / polymer bilayer film;

[0069] (4) The emission device wit...

Embodiment 3

[0071] This embodiment provides a SERS substrate, which includes a second metal film (silver, with a thickness of 50 nm) and a first metal film (aluminum and copper with a mass ratio of 1:1, with a thickness of 7 nm) stacked in sequence. and a polymer film (PMMA and PS at a mass ratio of 1:1, with a thickness of 40 nm).

[0072] This embodiment also provides the preparation method of described SERS substrate, and described preparation method comprises the following steps:

[0073] (1) Ultrasonic cleaning of the glass sheet with acetone, absolute ethanol and deionized water in sequence, drying in an oven after blowing with nitrogen, dissolving the polymers (PMMA and PS) in the solvent, ultrasonic vibration, and obtaining polymer solution;

[0074] (2) Spin-coat the polymer solution on a glass sheet at a speed of 10000r / min, and heat it at 60°C to obtain a polymer film;

[0075] (3) Depositing the first metal (aluminum and copper) film on the polymer film by ion sputtering to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com