Phosphoric acid-modified nano beta molecular sieve-ammonium polyphosphate composite flame retardant and preparation method thereof

A technology of composite flame retardant and β molecular sieve, which is applied in the field of halogen-free flame retardants, can solve the problems of serious hazards, low flame retardant effect, and limited application, and achieve good flame retardant performance, smoke suppression performance, and excellent toughening , Good dispersion and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

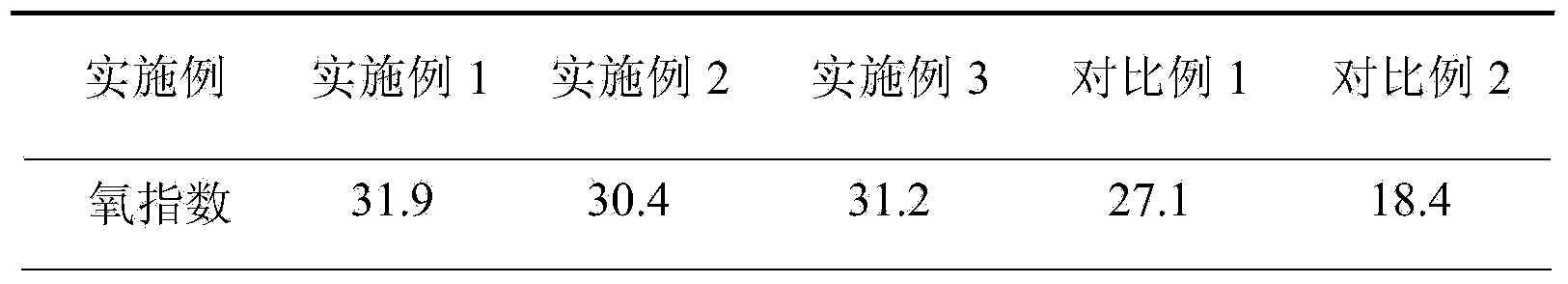

Embodiment 1

[0018] Weigh 4kg of nano-beta molecular sieve with a particle size of 90nm, add 20L of phosphoric acid aqueous solution with a concentration of 0.5mol / L, put it in an ultrasonic oscillator for 8 minutes, heat and reflux and stir for 25 minutes, filter, and put the filter residue in an oven to dry at 100°C Dry it, put it into a muffle furnace and bake it at 400°C for 3 hours, and then pulverize it to obtain phosphoric acid-modified nano-β molecular sieve.

[0019] First, add 70L of concentrated phosphoric acid with a concentration of 80% into a reaction kettle with a volume of 1000L, heat to 95°C, slowly add 90kg of urea under stirring, heat up to 130°C after the urea dissolves, then add 20kg of phosphoric acid modified nano-β molecular sieve, and stir After 8 minutes, the temperature was raised to 170°C for pre-polymerization, and the temperature was kept until the reactant was viscous, then transferred to an oven at 250°C for further polymerization reaction for 30 minutes, the...

Embodiment 2

[0021] Weigh 5kg of nano-beta molecular sieve with a particle size of 100nm, add 20L of phosphoric acid aqueous solution with a concentration of 0.9mol / L, put it in an ultrasonic oscillator for 10 minutes, heat and reflux and stir for 28 minutes, filter, and put the filter residue in an oven for drying at 105°C Dry it, put it into a muffle furnace and bake it at 450°C for 3.5 hours, and then pulverize it to obtain phosphoric acid-modified nano-β molecular sieve.

[0022] Add 50L of concentrated phosphoric acid with a concentration of 85% into a reactor with a volume of 1000L, heat to 85°C, slowly add 80kg of urea under stirring, heat up to 120°C after the urea dissolves, then add 10kg of phosphoric acid-modified nano-β molecular sieve, and stir for 10 minutes Finally, heat up to 150°C for pre-polymerization, keep warm until the reactants are viscous, transfer to an oven at 220°C for further polymerization for 20 minutes, discharge the material, cool and pulverize, sieve, and pa...

Embodiment 3

[0024] Weigh 6kg of nano-beta molecular sieve with a particle size of 120nm, add 20L of phosphoric acid aqueous solution with a concentration of 1.0mol / L, put it in an ultrasonic oscillator for 12min, heat and reflux and stir for 35min, filter, and put the filter residue in an oven for drying at 120°C Dry it, put it into a muffle furnace and bake it at 500°C for 4 hours, and then pulverize it to obtain phosphoric acid-modified nano-β molecular sieve.

[0025] Add 60L of concentrated phosphoric acid with a concentration of 82% into a reactor with a volume of 1000L, heat to 90°C, slowly add 85kg of urea under stirring, heat up to 125°C after the urea dissolves, then add 15kg of phosphoric acid modified nano-β molecular sieve, and stir for 12min Finally, the temperature was raised to 160°C for pre-polymerization, and the temperature was kept until the reactants were viscous, then transferred to an oven at 230°C for further polymerization for 25 minutes, the discharged material was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com