Spinneret, equipment and method for manufacturing high grammage spunbonded hot-rolled nonwoven fabric

A technology of non-woven fabrics and spinnerets, applied in the direction of non-woven fabrics, melt spinning, filament/thread forming, etc., can solve problems such as delamination, production of difficult high-weight products, etc., to avoid delamination, susceptible to heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below.

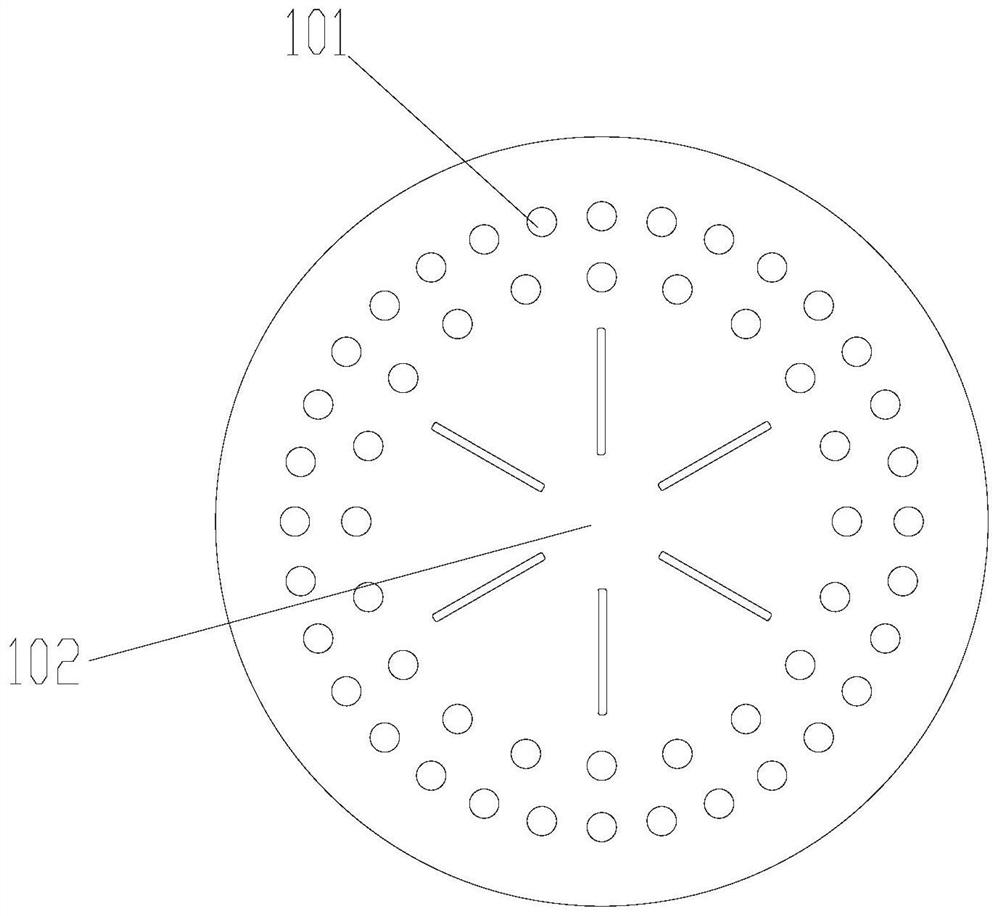

[0030] Such as figure 2 As shown, the spinneret 10 for manufacturing high-gram weight spunbond hot-rolled nonwovens includes a spinneret body, which is provided with several circular holes and several inline holes, and several circular holes. The holes form a circular hole area 101, and several inline holes form an inline hole area 102. The circular hole area 101 is located at the periphery of the inline hole area 102. Several inline holes are arranged in a circular array. The extension lines in the length direction of the inline holes all pass through the center of the circular array, and several circular holes are also arranged in a circular array. The ratio of the number of round holes to the number of straight holes is: 10:1~15:1. The ratio of the cross-sectional area of the circular hole to the cross-sectional area of the inline hole is 1:6 to 1:9.

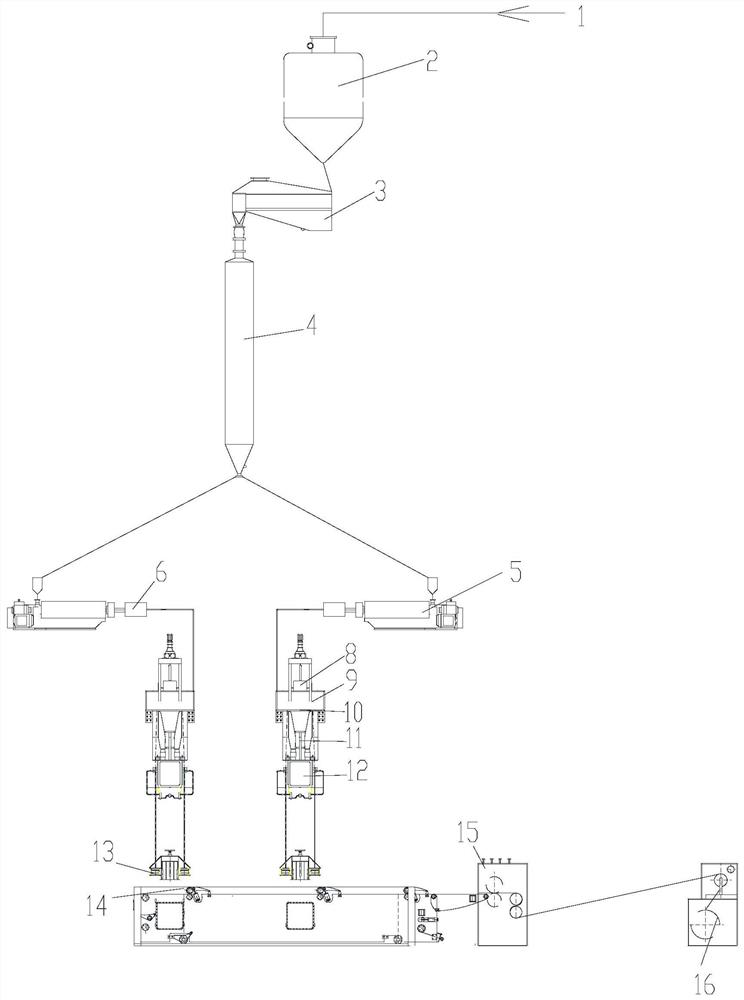

[0031] Such as figure 1 As shown, the eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com