Ethanol working medium hot dry rock geothermal heat pipe efficient heating system and method

A heating system and heat pipe technology, which is applied in the field of high-efficiency heating system of hot dry rock geothermal heat pipe, can solve the problems of fast load drop, water diffusion loss, and short vacuuming interval, so as to achieve stable load and operating temperature, reduce resistance, reduce carrying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

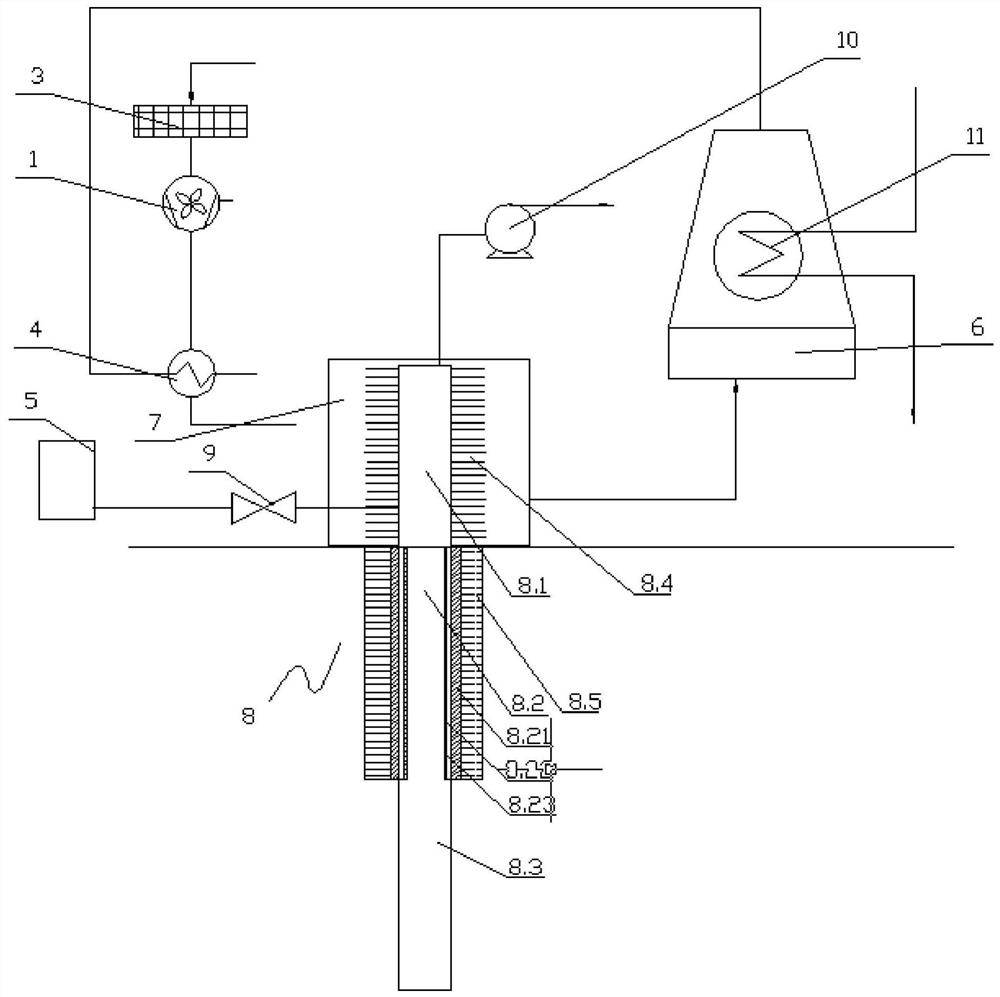

[0024] Such as figure 1 As shown, the present invention comprises blower fan 1, vacuum pump 11, wire mesh filter 3, regenerator 4, ethanol storage tank 5, heat exchange chamber 6, the heating box 7 that is placed on the ground and the heat pipe 8 that is vertically buried in the ground, heating The box 7 is a closed structure, and the liquid levels at both ends of the heat pipe are closed.

[0025] The heat pipe 8 adopts a stainless steel pipe, the outer diameter of the heat pipe 10 is 100-500mm, and the height of the heat pipe 8 is 1-1.5km; the heat pipe 8 includes a condensation section 8.1, a heat preservation section 8.2, an evaporation section 8.3, and a condensation section 8.1 arranged in sequence from top to bottom. Extend upwards into the heating box 7, and the outer wall is connected with fins 8.4, the heat pipe 8 and the heating box 7 are sealed and connected, the heat preservation section 8.2 and the evaporation section 8.3 are located below the ground, and the len...

no. 2 example

[0036]The difference between the second embodiment and the first embodiment is that the condensation section of the heat pipe adopts a zigzag structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com