Composite insulator and method for detecting brittle failure of composite insulator based on fiber gratings

A technology of composite insulators and optical fiber gratings, which is applied in the direction of insulators, the measurement of the change force of the optical properties of the material when it is stressed, and the measurement of force, can solve the problem of not being able to find the brittle fracture of composite insulators, and monitoring the operating status of composite insulators. To achieve the effect of good insulation, intuitive identification and positioning, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

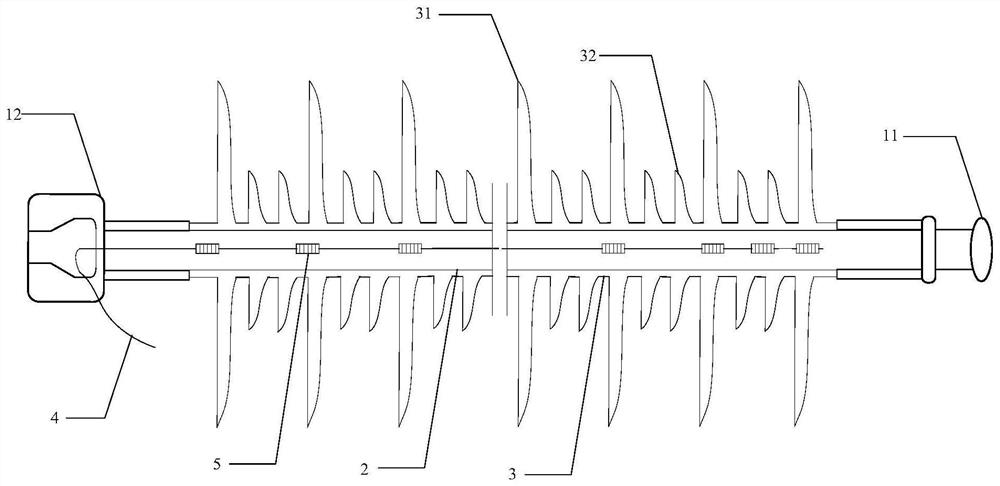

[0028] The composite insulator provided in this embodiment includes a mandrel 2, high-voltage end fittings 11 and low-voltage end fittings 12 respectively arranged at both ends of the mandrel 2, a sheath 3 coated on the mandrel 2, and a The umbrella skirt, in this embodiment, the sheath 3 is a silicone rubber sheath, and the umbrella skirt includes a large umbrella 31 and a small umbrella 32 .

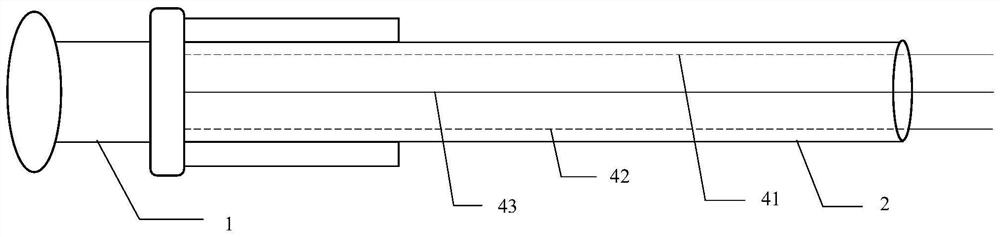

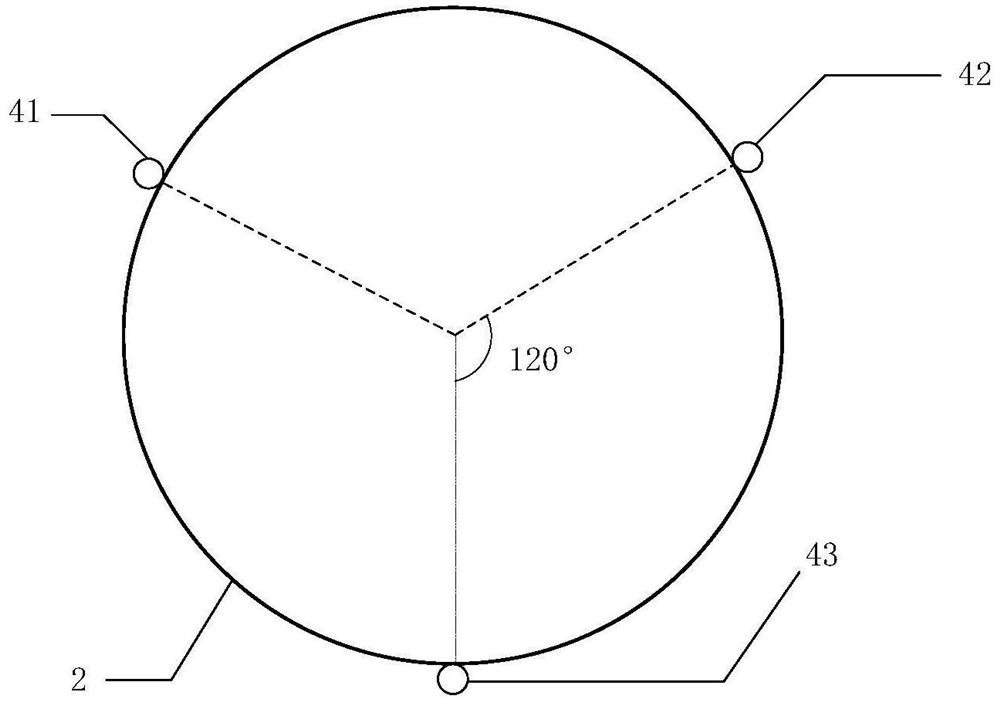

[0029] In order to effectively monitor the three-dimensional axial stress change and physical state of the core rod 2 surface during the brittle fracture of the composite insulator, at least two optical fibers 4 are arranged between the core rod 2 and the sheath 3 of the composite insulator, and each optical fiber 4 A plurality of fiber Bragg gratings 5 for obtaining wavelength offsets to judge brittleness are arranged along the length direction. Specifically, in this embodiment, three optical fibers 4 are provided, which are respectively defined as 1# optical fibers 41, 2 #optical f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com