Method for preparing mixed-valence (Cr(IV) and Cr(VI)) chromate Ca5Cr3O12

A mixed valence, ca5cr3o12 technology, applied in the direction of chromate/dichromate, etc., can solve the problems of residue, large calcination temperature span, low yield, etc., to achieve increased yield, convenient reaction process, and high output rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

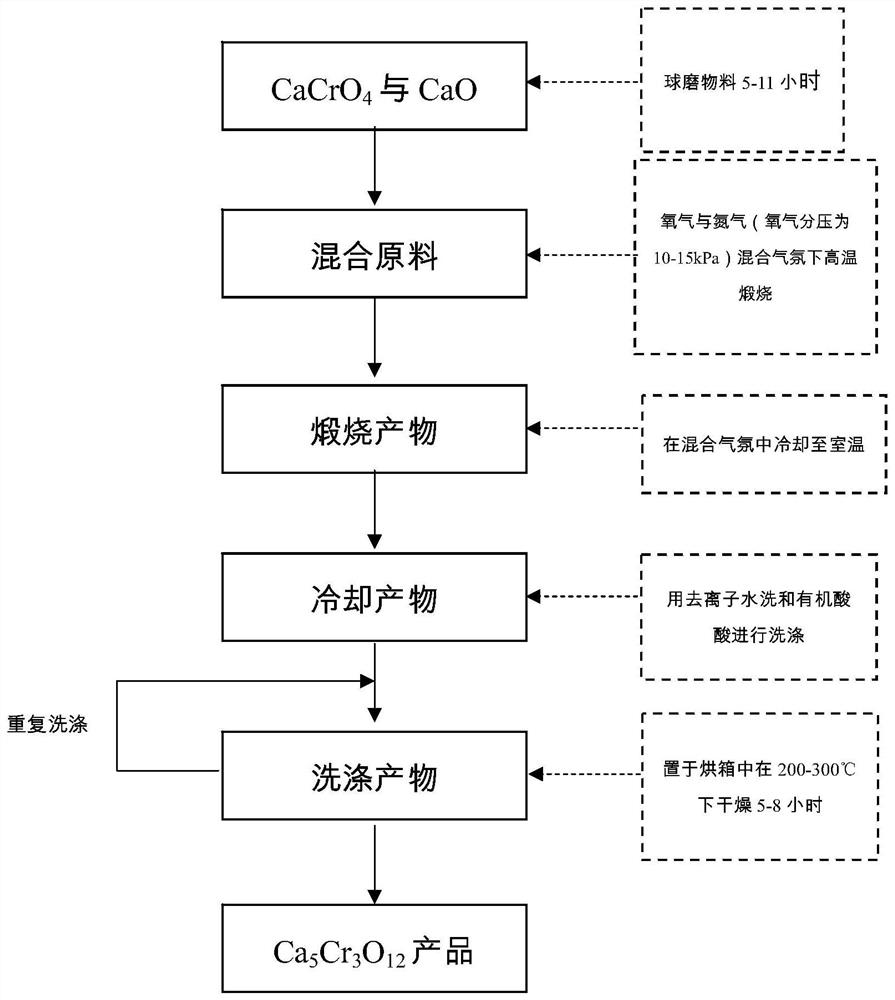

Method used

Image

Examples

Embodiment 1

[0021] CaO and CaCrO 4 The mixture is mixed with a ball mill, the mass percentage of CaO in the raw material is 40%, CaCrO 4 The mass percentage is 60%, and the mixed raw materials are calcined at a high temperature in an atmosphere box furnace in a mixed atmosphere of oxygen and nitrogen (oxygen partial pressure is 10kPa), the calcination temperature is 1300 ° C, and the calcination time is 5h. The calcined product is cooled in a mixed atmosphere, and the product is washed with deionized water, and then the cooled product is washed with formic acid with a pH value of 5. The solid-to-liquid ratio of the acid to the washed sample is 1:15. After 1 hour of separation of the product, use a suction filter to separate, pickle the filter residue once more according to the above process, wash the filter residue with deionized water and filter. The filter residue obtained after suction filtration was dried in an oven for 5 hours, the drying temperature was maintained at 200°C, and the...

Embodiment 2

[0023] CaO and CaCrO 4 The mixture is mixed with a ball mill, wherein the mass percentage of CaO is 30%, and the mixed raw material is calcined at a high temperature in an atmosphere box furnace in a mixed atmosphere of oxygen and nitrogen (oxygen partial pressure is 15kPa), and the calcining temperature is 1400°C. Calcination time is 6h. The calcined product is cooled in a mixed atmosphere, and the product is washed with deionized water, and then the cooled product is washed with formic acid with a pH value of 6. The solid-to-liquid ratio of the acid to the washed sample is 1:10. After 1 hour of separation of the product, use a suction filter to separate, pickle the filter residue once more according to the above process, wash the filter residue with deionized water and filter. The filter residue obtained after suction filtration was dried in an oven for 5 hours, the drying temperature was maintained at 250°C, and the obtained product was Ca with a purity of 89%. 5 Cr 3 o ...

Embodiment 3

[0025] CaO and CaCrO 4 The mixture is mixed with a ball mill, wherein the mass percentage of CaO is 50%, and the mixed raw material is calcined at a high temperature in an atmosphere box furnace in a mixed atmosphere of oxygen and nitrogen (oxygen partial pressure is 13kPa), and the calcining temperature is 1400°C. Calcination time is 8h. The calcined product is cooled in a mixed atmosphere, and the product is washed with deionized water, and then the cooled product is washed with acetic acid with a pH value of 5. The solid-to-liquid ratio of the acid to the washed sample is 1:20. After 1 hour of separation of the product, use a suction filter to separate, pickle the filter residue once more according to the above process, wash the filter residue with deionized water and filter. The filter residue obtained after suction filtration was dried in an oven for 6 hours, the drying temperature was maintained at 300°C, and the obtained product was Ca with a purity of 86%. 5 Cr 3 o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com