High-salinity sewage treatment process

A technology of high-salt sewage and treatment process, which is applied in water/sewage treatment, heating water/sewage treatment, light water/sewage treatment, etc. problems, to achieve the effect of solving product acidification, high water quality standards, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

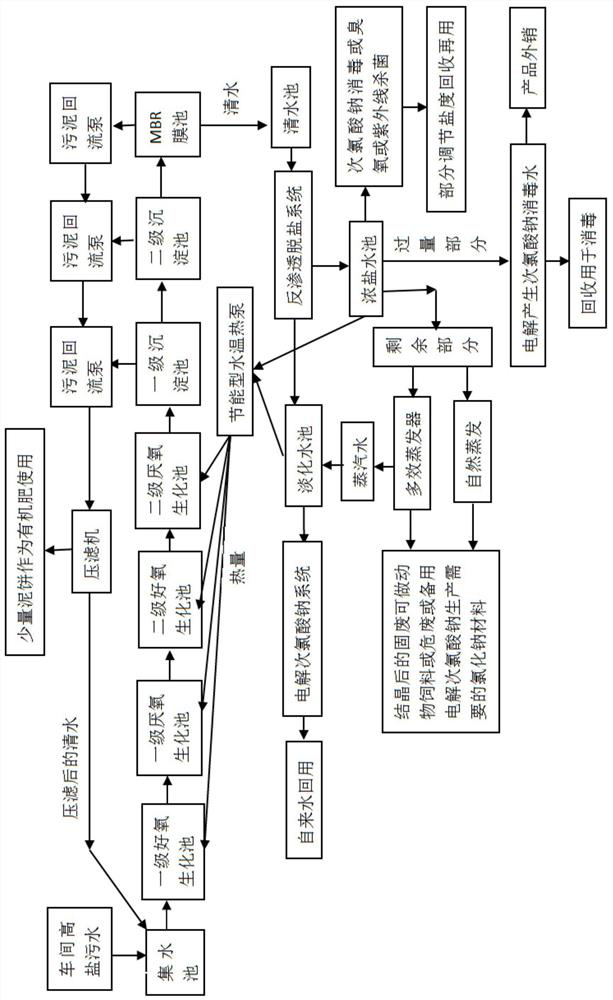

[0012] The present invention will be further described below in conjunction with the accompanying drawings and examples.

[0013] The high-salt sewage treatment process provided by the invention, such as figure 1 As shown, firstly, the high-salt sewage generated by each shift in the workshop is collected to the sump to buffer and balance the water quality. Here, due to the production shift process of the workshop and other reasons, the water quality of the collected high-salt sewage fluctuates greatly, so it is concentrated in the sump Buffer and balance the water quality, which is to ensure the balance and stability of the water quality entering the next biochemical system; then carry out two-stage biochemical treatment in the biochemical system, that is, lead the sewage to the first-level aerobic biochemical pool, the first-level anaerobic biochemical pool, and the second-level The two-stage biochemical treatment is carried out in the aerobic biochemical pool and the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com