Foaming agent for admixture foam light soil and preparation method thereof

A technology of foam light soil and foaming agent, which is applied in the field of building materials, can solve the problems of unsatisfactory performance of admixture foam light soil, and achieve the effect of good performance, high-efficiency quality, technical and economic goals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

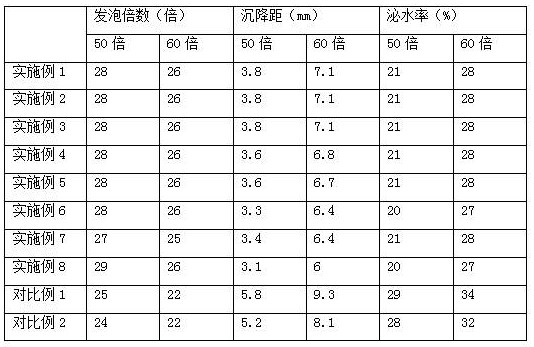

Examples

Embodiment 1

[0038] A foaming agent for admixture foam light soil, comprising the following raw materials in parts by weight: 200 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 30 parts of silicone resin polyether emulsion, 50 parts of magnesium chloride, 150 parts of n-butanol parts and 180 parts of water.

[0039] Described a kind of preparation method for the foaming agent of admixture foam light soil, comprises the following steps:

[0040] (1) Take by weight the parts by weight of each raw material of the foaming agent used for the admixture foam light soil;

[0041] (2) First add 180 parts of water to the reactor, start the heater, and heat while stirring;

[0042] (3) When the water temperature rises to 40 degrees Celsius, stop heating, and add 150 parts of diluent to the reaction kettle;

[0043] (4) Add 200 parts of foaming agent into the reactor and stir until uniform;

[0044] (5) Finally, add 30 parts of foam stabilizer to the reactor and stir evenly;

[0045]...

Embodiment 2

[0047] A foaming agent for admixture foam light soil, comprising the following raw materials in parts by weight: 250 parts of sodium lauryl sulfate, 40 parts of coconut oil fatty acid diethanolamide, 60 parts of sodium silicate, sec-butanol 180 parts and 200 parts water.

[0048] Described a kind of preparation method for the foaming agent of admixture foam light soil, comprises the following steps:

[0049] (1) Take by weight the parts by weight of each raw material of the foaming agent used for the admixture foam light soil;

[0050] (2) First add 200 parts of water to the reactor, start the heater, and heat while stirring;

[0051] (3) When the water temperature rises to 40 degrees Celsius, stop heating and add 180 parts of diluent to the reaction kettle;

[0052] (4) Add 250 parts of foaming agent into the reactor and stir until uniform;

[0053] (5) Finally, add 40 parts of foam stabilizer to the reactor and stir evenly;

[0054] (6) After the above materials are unif...

Embodiment 3

[0056] A foaming agent for admixture foam light soil, comprising the following raw materials in parts by weight: 300 parts of tea saponin, 40 parts of hydroxypropyl methylcellulose, 60 parts of triethanolamine, 180 parts of ethanol and 205 parts of water share.

[0057] Described a kind of preparation method for the foaming agent of admixture foam light soil, comprises the following steps:

[0058] (1) Take by weight the parts by weight of each raw material of the foaming agent used for the admixture foam light soil;

[0059] (2) First add 205 parts of water to the reactor, start the heater, and heat while stirring;

[0060] (3) When the water temperature rises to 40 degrees Celsius, stop heating and add 180 parts of diluent to the reaction kettle;

[0061] (4) Add 300 parts of foaming agent into the reactor and stir until uniform;

[0062] (5) Finally, add 40 parts of foam stabilizer to the reactor and stir evenly;

[0063] (6) After the above materials are uniform, add 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com