Anti-rutting drainage asphalt mixture and preparation method thereof

A technology of drainage asphalt and asphalt mixture, applied in the field of asphalt, can solve the problems of road performance, road oxidation, reduced drainage efficiency, prone to cracks, ruts, potholes, etc., to enhance the ability to disperse stress and reduce protruding edges and corners , the effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

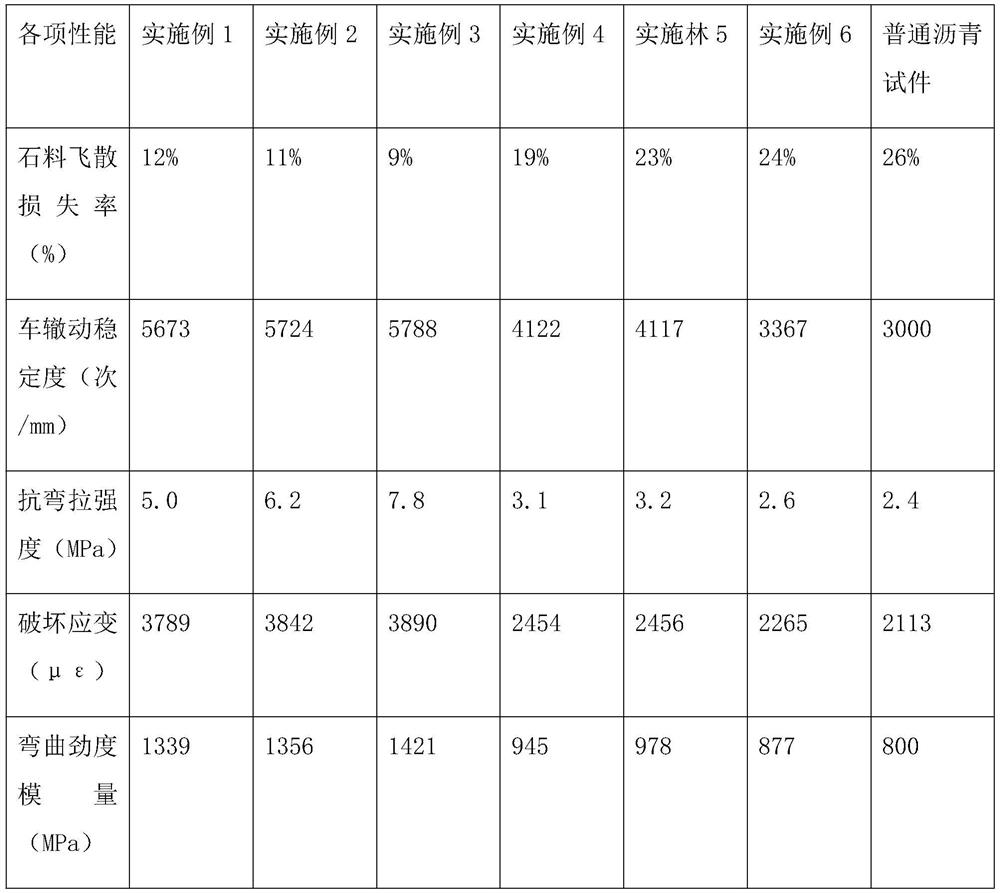

Examples

Embodiment 1

[0050] A rutting-resistant drainage asphalt mixture, the raw material components are as follows: in parts by weight, 100 parts of epoxy asphalt, 60 parts of mineral fiber, 40 parts of styrene, 40 parts of butadiene, 20 parts of initiator , 30 parts of polymerized monomer, 80 parts of carboxyl silicone oil, 30 parts of n-hexylamine, 10 parts of dithiothreitol, 60 parts of carbonate solution, and 60 parts of calcium lactate.

[0051] The polymerized monomers include the following raw material components: in parts by weight, 100 parts of 4-vinylbenzyl chloride monomer, 60 parts of sodium thioacetate, and 70 parts of modified aggregate.

[0052] The modified aggregate includes the following raw material components: in parts by weight, 30 parts of epoxy-based silicone oil, 30 parts of hydroxyl silicone oil, 10 parts of acid-binding agent, 40 parts of 2-bromoisobutyryl bromide, 40 parts of cuprous bromide 30 parts, 30 parts of pentamethyldiethylenetriamine, 25 parts of dodecafluoroh...

Embodiment 2

[0067] A rutting-resistant drainage asphalt mixture, the raw material components are as follows: in parts by weight, 150 parts of epoxy asphalt, 70 parts of mineral fiber, 60 parts of styrene, 60 parts of butadiene, 25 parts of initiator , 40 parts of polymerized monomer, 90 parts of carboxyl silicone oil, 45 parts of n-hexylamine, 20 parts of dithiothreitol, 70 parts of carbonate solution, and 70 parts of calcium lactate.

[0068] The polymerized monomers include the following raw material components: in parts by weight, 150 parts of 4-vinylbenzyl chloride monomer, 70 parts of sodium thioacetate, and 75 parts of modified aggregate.

[0069] The modified aggregate includes the following raw material components: in parts by weight, 35 parts of epoxy silicone oil, 35 parts of hydroxyl silicone oil, 15 parts of acid binding agent, 50 parts of 2-bromoisobutyryl bromide, 50 parts of cuprous bromide Parts, 35 parts of pentamethyldiethylenetriamine, 30 parts of dodecafluoroheptyl acr...

Embodiment 3

[0084] A kind of anti-rutting drainage asphalt mixture, the raw material components are as follows: in parts by weight, 200 parts of epoxy asphalt, 80 parts of mineral fiber, 80 parts of styrene, 80 parts of butadiene, 30 parts of initiator , 50 parts of polymerized monomer, 100 parts of carboxyl silicone oil, 60 parts of n-hexylamine, 30 parts of dithiothreitol, 80 parts of carbonate solution, and 80 parts of calcium lactate.

[0085]The polymerized monomers include the following raw material components: in parts by weight, 200 parts of 4-vinylbenzyl chloride monomer, 80 parts of sodium thioacetate, and 80 parts of modified aggregate.

[0086] The modified aggregate includes the following raw material components: in parts by weight, 40 parts of epoxy-based silicone oil, 40 parts of hydroxyl silicone oil, 20 parts of acid-binding agent, 60 parts of 2-bromoisobutyryl bromide, 60 parts of cuprous bromide 40 parts, 40 parts of pentamethyldiethylenetriamine, 35 parts of dodecafluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com