Spherical granulation method of potash magnesium sulphate fertilizer

A potassium-magnesium sulfate fertilizer and potassium-magnesium fertilizer technology, applied in potash fertilizers, inorganic fertilizers, fertilization devices, etc., can solve the problems of high equipment maintenance costs, poor fluidity, and high particle strength, so as to eliminate the introduction of invalid components, uniformity and The effect of good fluidity and high particle strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The embodiments are specifically implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operation processes are given. The raw materials involved in the embodiments are all from SDIC Xinjiang Lop Nur Potassium Salt Co., Ltd.

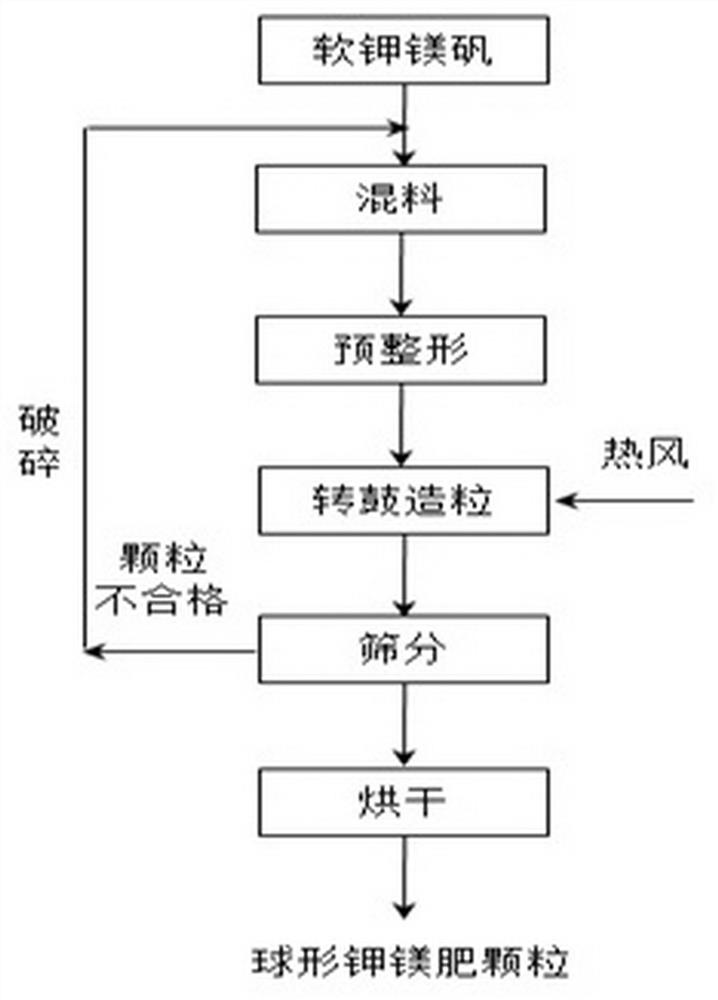

[0011] A method for spherical granulation of potassium magnesium sulfate fertilizer, implemented according to the following steps: as figure 1 As shown, take the refined soft potassium magnesium fertilizer with a free water content of 16.32%, and the returned material crushed to a particle size of <2mm, with a free water content of 3.66%, and mix them evenly in a ratio of 7:3 by mass to obtain a free water content It is 15.1% of the mixture, which enters the spiral shaping machine for pre-shaping, drum granulator granulation, screening, and drying to obtain sph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com